Cereal fruit beverage and preparation method thereof

A beverage and fruit technology, which is applied in the field of miscellaneous grain and fruit beverages and its preparation, can solve problems such as indigestion and early satiety, and achieve the effects of simple operation, high nutritional value, and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]

[0038]

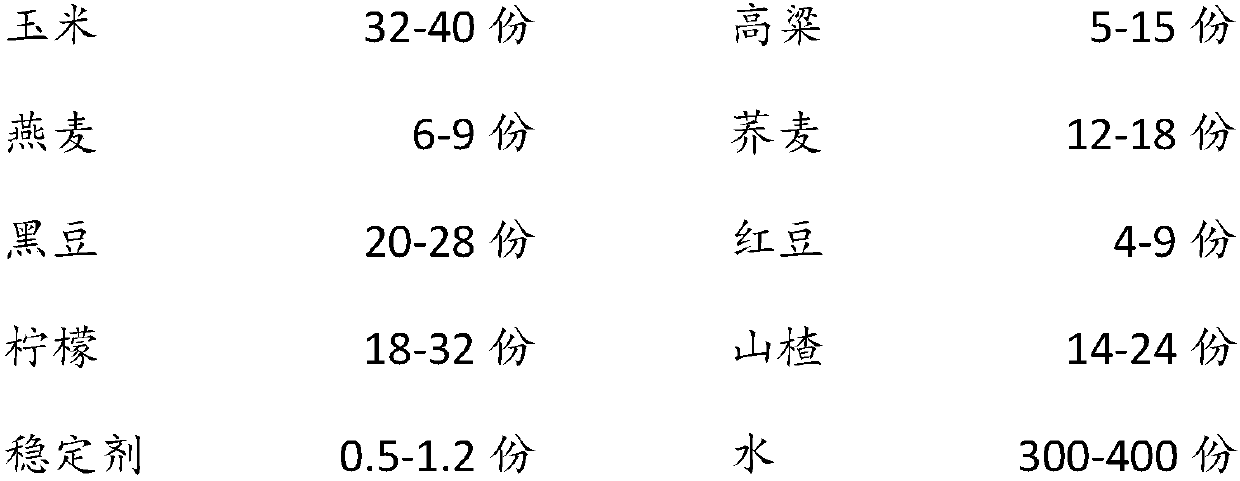

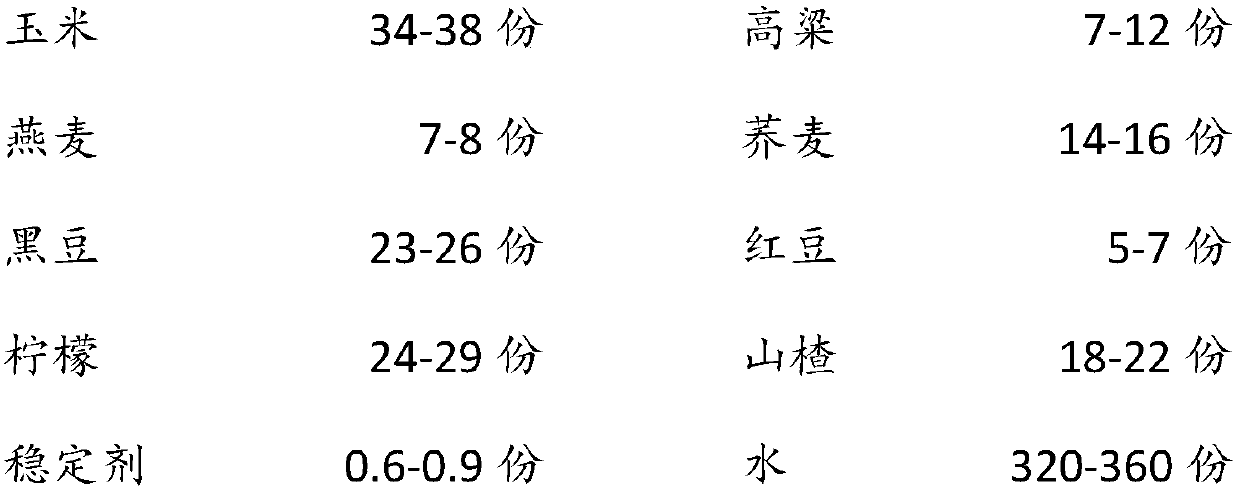

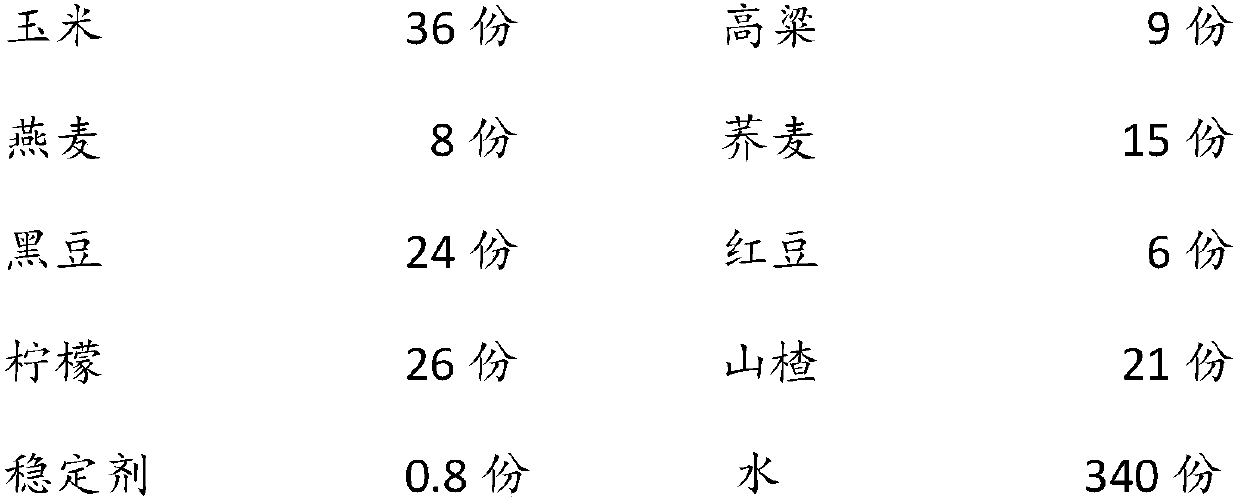

[0039] Multigrain fruit beverage, its raw material components include:

[0040] Its production method is:

[0041] Corn, sorghum, oats, buckwheat, black beans, red beans, lemons, and hawthorns are respectively subjected to impurity removal treatment, and all mud, mildew, insect damage, sprouts, peels, and cores must be selected;

[0042] Soak corn, sorghum, oats, buckwheat, black beans, red beans, lemons, and hawthorn in water for 2 hours, take them out, and dry them at 60°C for 40 minutes;

[0043] The dried corn, sorghum, oats, buckwheat, black beans, red beans, lemons and hawthorn are respectively pulverized with an ultrafine pulverizer to obtain corn flour, sorghum flour, oat flour, buckwheat flour, black bean flour, and red bean flour. powder, lemon powder and hawthorn powder;

[0044] Pour corn flour, sorghum flour, oat flour, buckwheat flour, black bean flour, and red bean flour into the high-speed shear tank, pour 2 / 3 of the component amount o...

Embodiment 2

[0050]

[0051]

[0052] Multigrain fruit beverage, its raw material components include:

[0053] Its production method is:

[0054] Corn, sorghum, oats, buckwheat, black beans, red beans, lemons, and hawthorns are respectively subjected to impurity removal treatment, and all mud, mildew, insect damage, sprouts, peels, and cores must be selected;

[0055] Soak corn, sorghum, oats, buckwheat, black beans, red beans, lemons, and hawthorn in water for 1.2 hours, take them out, and dry them at 52°C for 38 minutes;

[0056] The dried corn, sorghum, oat, buckwheat, black bean, red bean, lemon and hawthorn are respectively pulverized with an ultrafine pulverizer to obtain corn flour, sorghum flour, oat flour, buckwheat flour, black bean flour, and red bean flour. powder, lemon powder and hawthorn powder;

[0057] Pour corn flour, sorghum flour, oat flour, buckwheat flour, black bean flour, and red bean flour into the high-speed shear tank, pour 2 / 3 components of 92°C water, set...

Embodiment 3

[0063]

[0064] Multigrain fruit beverage, its raw material components include:

[0065] Its production method is:

[0066] Corn, sorghum, oats, buckwheat, black beans, red beans, lemons, and hawthorns are respectively subjected to impurity removal treatment, and all mud, mildew, insect damage, sprouts, peels, and cores must be selected;

[0067] Soak corn, sorghum, oats, buckwheat, black beans, red beans, lemons, and hawthorn in water for 1 hour, take them out, and dry them at 50°C for 30 minutes;

[0068] The dried corn, sorghum, oats, buckwheat, black beans, red beans, lemons and hawthorn are respectively pulverized with an ultrafine pulverizer to obtain corn flour, sorghum flour, oat flour, buckwheat flour, black bean flour, and red bean flour. powder, lemon powder and hawthorn powder;

[0069] Pour corn flour, sorghum flour, oat flour, buckwheat flour, black bean flour, and red bean flour into the high-speed shear tank, pour 2 / 3 of the component amount of 100°C water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com