Preparation method of nitrogen content-adjustable nitrogen-doped ordered mesoporous carbon

A nitrogen-containing, porous carbon technology is applied in the field of preparation of nitrogen-doped ordered mesoporous carbon, which can solve the problems of long aging time, high reaction temperature, time-consuming and energy consumption, and achieves simple process, mild reaction conditions, The effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

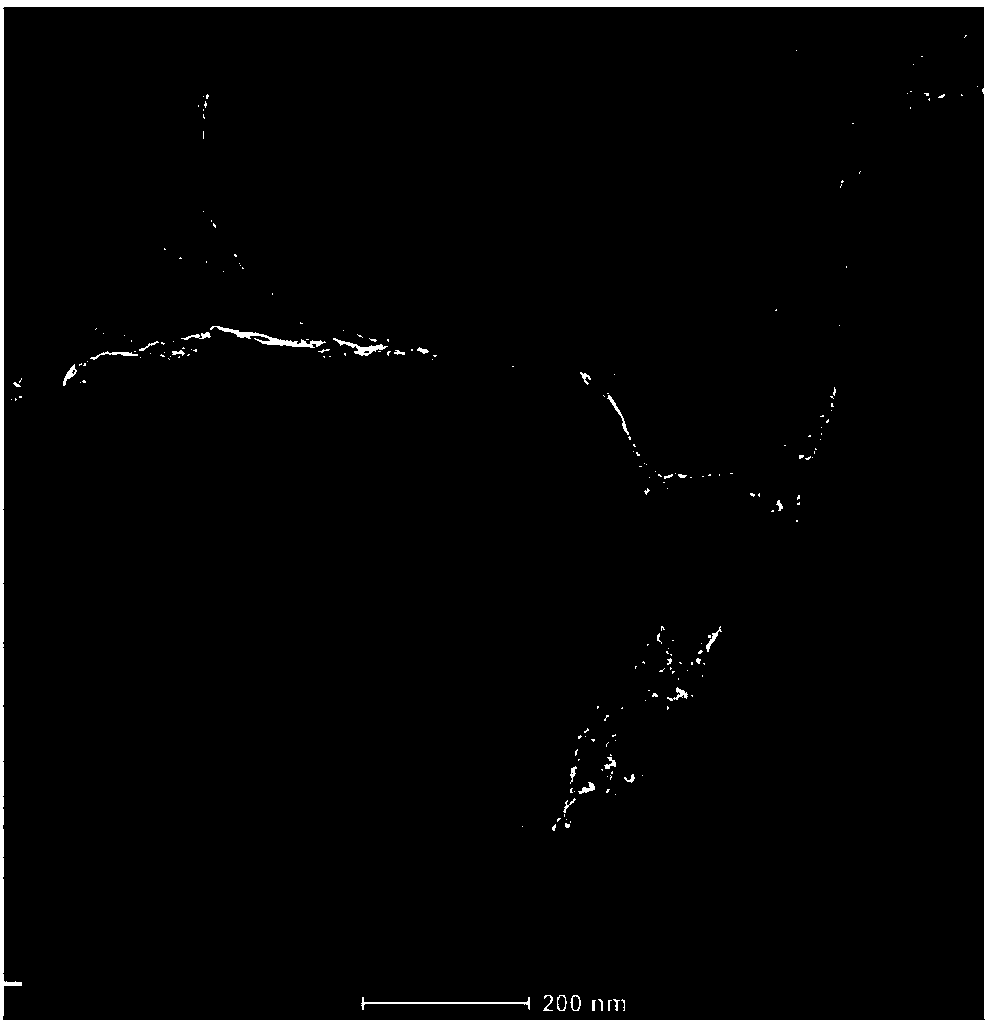

Image

Examples

Embodiment 1

[0017] 28 mg Na at 20°C 2 CO 3 Dissolve 1.68 g of bis-nitrile amine with 11.3 g of 37% formaldehyde solution, add 11.0 g of resorcinol under stirring, and stir for 4 h. Subsequently, the above mixed solution was added to 8.0 g of F127 solution dissolved in 40 mL of water and 64 mL of ethanol, and 5 mL of hydrochloric acid with a concentration of 2 mol / L was added rapidly, and the reaction was stirred for 2 h. After aging at room temperature for 12 h, the supernatant was discarded and dried at 100 °C for 12 h. The dried samples were placed in a tube furnace and carbonized at 600 °C for 3 h under the protection of nitrogen. Nitrogen-doped ordered mesoporous carbon was obtained by heating at 600 °C for 3 h at a rate of 2 °C / min and cooling to room temperature naturally.

Embodiment 2

[0019] 28 mg Na at 20°C 2 CO 3 Dissolve 2.52 g of bis-nitrile amine with 11.3 g of 37% formaldehyde solution, add 11.0 g of resorcinol under stirring, and stir for 3 h. Subsequently, the above mixed solution was added to 8.0 g of F127 solution dissolved in 40 mL of water and 64 mL of ethanol, and 5 mL of hydrochloric acid with a concentration of 2 mol / L was added quickly, and the reaction was stirred for 1 h. After aging at room temperature for 12 h, the supernatant was discarded and dried at 100 °C for 12 h. The dried samples were placed in a tube furnace and carbonized at 600 °C for 3 h under the protection of nitrogen. Nitrogen-doped ordered mesoporous carbon was obtained by heating at 600 °C for 3 h at a rate of 2 °C / min and cooling to room temperature naturally.

Embodiment 3

[0021] 28 mg Na at 20°C 2 CO 3 and 3.36 g of bis-nitrile amine were dissolved with 11.3 g of 37% formaldehyde solution, and 11.0 g of resorcinol was added under stirring, and the reaction was stirred for 2 h. Subsequently, the above mixed solution was added to 8.0 g of F127 solution dissolved in 40 mL of water and 64 mL of ethanol, and 5 mL of hydrochloric acid with a concentration of 2 mol / L was added quickly, and the reaction was stirred for 1 h. After aging at room temperature for 12 h, the supernatant was discarded and dried at 100 °C for 12 h. The dried samples were placed in a tube furnace and carbonized at 600 °C for 3 h under the protection of nitrogen. Nitrogen-doped ordered mesoporous carbon was obtained by heating at 600 °C for 3 h at a rate of 2 °C / min and cooling to room temperature naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com