Fermentation medium and production process for producing oritavancin precursor A82846B

A technology of A82846B, fermentation medium, applied in the field of fermentation medium, can solve the problems of low yield and high impurity content, and achieve the effect of increased yield, low impurity content, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this example 1, in the fermentation medium, glucose is used as the carbon source, and its dosage is 5.0%, and the other conditions and production process are the same as those of comparative example 1.

[0049] As determined by HPLC, the yield of A82846B was 1600mg / L. It can be seen that when 5.0% glucose is used as the carbon source, the yield of A82846B is increased by 11.3% compared to Comparative Example 1.

Embodiment 2-3

[0055] In Examples 2 and 3, glucose was used as the carbon source in the fermentation medium, and the dosages were 6.5% and 8.0% respectively, and other conditions and production processes were the same as in Comparative Example 1.

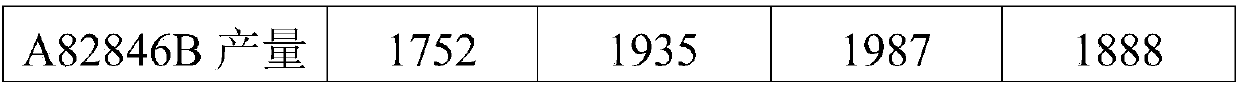

[0056] As determined by HPLC, the yield of A82846B is as follows:

[0057] Numbering

[0058] It can be seen that the best fermentation result is when 8.0% glucose is used as the carbon source, and the yield of A82846B is increased by 19.96% compared with Comparative Example 1.

Embodiment 4

[0068] In Example 4, in the fermentation medium, the carbon source is glucose, and its dosage is 8.0%; the nitrogen source is yeast powder, and its dosage is 0.5%; other conditions and production process are the same as those of Comparative Example 1.

[0069] As determined by HPLC, the yield of A82846B was 1790mg / L. In combination with Comparative Examples 9-11, it can be seen that the best fermentation result is using 0.5% yeast powder as nitrogen source, and the yield of A82846B is increased by 24.48% compared with Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com