Manufacturing enterprise resource recovery cloud service system and method

A technology of enterprise resources and resource recycling, which is applied in the field of manufacturing enterprise resource recycling cloud service system, can solve problems such as imperfection, pollution, and low efficiency of resource recycling, so as to reduce intermediate transaction links, increase favorability, and ensure stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

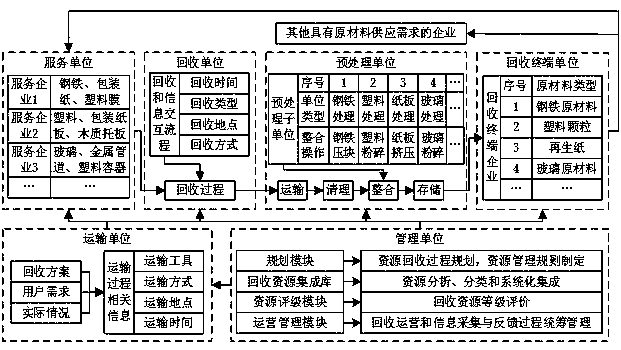

[0031] Embodiment 1: as figure 1 As shown, this embodiment provides a manufacturing enterprise resource recycling cloud service system, including: service unit, recycling unit, preprocessing unit, recycling terminal unit, transportation unit, and management unit.

[0032] Among them, the service unit will produce recyclable waste resources including substandard parts, waste, packaging materials, obsolete equipment, and worn tools during the process of processing products, and needs to purchase raw materials used in the processing and manufacturing process. A collection of different types of manufacturing enterprises that meet the needs of resource recycling, including multiple service enterprises. For example, service enterprise 1 is mainly engaged in the manufacture of steel products, has input demand for steel raw materials, and outputs steel waste, packaging paper, plastic film, etc. Recycling resources, service enterprise 2 is mainly engaged in the manufacture of injection...

Embodiment 2

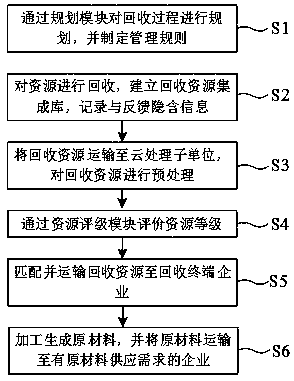

[0040] Embodiment 2: as figure 2 As shown, this embodiment provides a manufacturing enterprise resource recycling cloud service method, which is characterized in that it includes the steps:

[0041] S1: Plan the resource recycling process through the planning module, and formulate management rules including the time delay requirements of the recycling process, delay compensation standards, resource classification standards, classification methods, and rating standards;

[0042] S2: The recycling unit recycles resources from multiple service companies within the service unit, and further establishes a recycling resource integration library, so as to classify and systematically integrate resources, record the implicit information of recycled resources, and further feed back the implicit information to service companies;

[0043] S3: The transportation unit transports the recycled resources to the corresponding preprocessing sub-units in the preprocessing unit according to the ...

Embodiment 3

[0047] Embodiment 3: This embodiment provides an example of executing the recycling process according to the recycling and information interaction process as follows: Through the cooperation agreement reached with the injection molding service enterprise 2, it is arranged by the transportation unit at 8:00-10:00 every morning 1 No. transport vehicle recycles waste plastic resources, packaging cardboard, wooden pallets, scrap injection molding equipment, etc. in the A factory area, and further transports the recycled resources to the preprocessing unit. During the resource recovery process, the management unit records the category of each recycled resource and the weight or quantity of resources, check the appearance of scrapped plastic workpieces by means of sampling inspection, so as to record the location where the scrapped defective products are faulty or incomplete, analyze the reasons for scrapping according to the recorded results, and feed back the information of common s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com