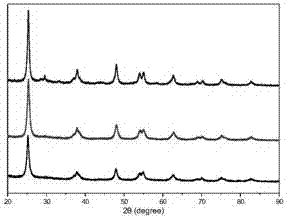

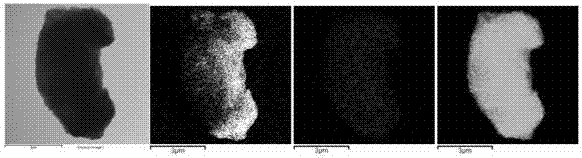

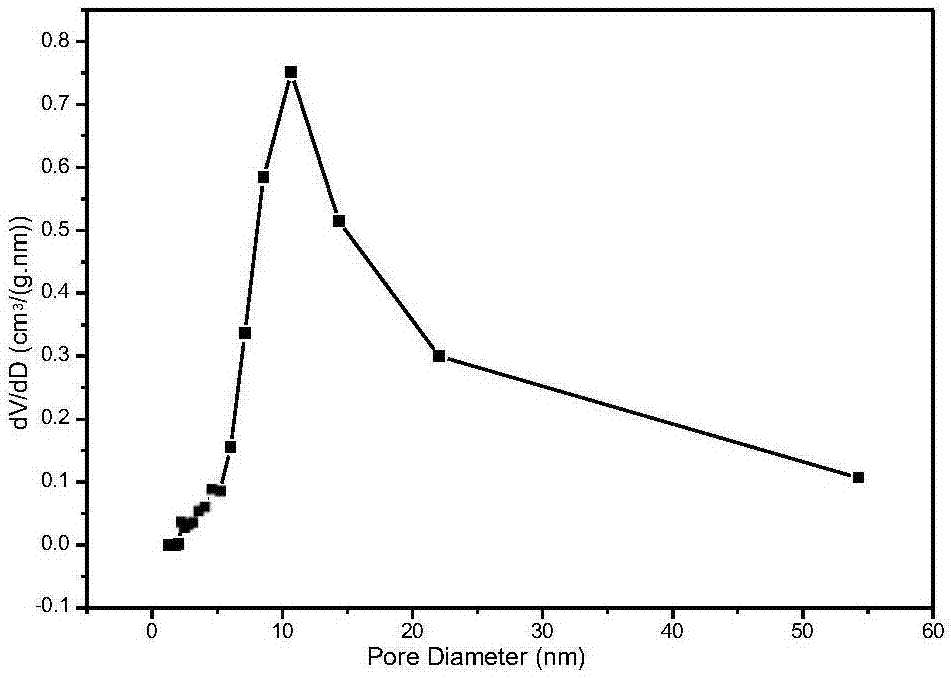

Preparation method of monoatomic catalyst by taking mesoporous titania as carrier

A mesoporous titanium dioxide and catalyst technology, which is applied in the field of single-atom catalyst preparation, can solve the problems of harsh process, complexity, and incapability of large-scale production, and achieve the effect of simple preparation process, mild reaction conditions and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The method for preparing a single-atom catalyst using mesoporous titanium dioxide as a carrier described in this example specifically includes the following steps:

[0021] (1) Dissolve 1.0 g of P123 in 30 g of ethanol solvent, stir at room temperature for 30 minutes to completely dissolve;

[0022] (2) After the P123 is completely dissolved, add 0.55 g of concentrated sulfuric acid (96%) and 1.5 g of concentrated hydrochloric acid (32%) dropwise to the solution, and fully stir to make it evenly mixed;

[0023] (3) Add 3.6 g of isopropyl titanate dropwise to the above solution, and stir at room temperature for 6 hours;

[0024] (4) Add 2ml of chloropalladium acid solution (0.01mol / L) to the above solution, ultrasonically disperse for 30 minutes, then stir at room temperature for 8 hours

[0025] (5) Transfer the above solution to a petri dish, place it in a fume hood and let it stand for 48 hours until the solvent evaporates, then put it in a drying oven and dry it at ...

Embodiment 2

[0029] The method for preparing a single-atom catalyst using mesoporous titanium dioxide as a carrier described in this example specifically includes the following steps:

[0030] (1) Dissolve 1.0 g of P123 in 30 g of ethanol solvent, stir at room temperature for 30 minutes to completely dissolve;

[0031] (2) After the P123 is completely dissolved, add 0.55 g of concentrated sulfuric acid (96%) and 1.5 g of concentrated hydrochloric acid (32%) dropwise to the solution, and fully stir to make it evenly mixed;

[0032] (3) Add isopropyl titanate dropwise to the above solution, and stir at room temperature for 3 hours;

[0033] (4) Add 4ml of chloropalladium acid solution (0.01mol / L) to the above solution, ultrasonically disperse for 30 minutes, then stir at room temperature for 8 hours;

[0034] (5) Transfer the above solution to a petri dish, place it in a fume hood and let it stand until the solvent evaporates, then put it in a drying oven and dry it at 100°C for 24 hours; ...

Embodiment 3

[0038] The method for preparing a single-atom catalyst using mesoporous titanium dioxide as a carrier described in this example specifically includes the following steps:

[0039] (1) Dissolve 2.0g of P123 in 50g of ethanol solvent, stir at room temperature for 30 minutes to completely dissolve;

[0040] (2) After the P123 is completely dissolved, add 1.0 g of concentrated sulfuric acid (96%) and 2.0 g of concentrated nitric acid (67%) dropwise to the solution, and fully stir to make it evenly mixed;

[0041] (3) Add 3.6 g of isopropyl titanate dropwise to the above solution, and stir at room temperature for 6 hours;

[0042] (4) Add 15ml of chloropalladium acid solution (0.01mol / L) to the above solution, ultrasonically disperse for 30 minutes, then stir at room temperature for 8 hours;

[0043] (5) Transfer the above solution to a petri dish, place it in a fume hood and let it stand for 72 hours until the solvent evaporates, then put it in a drying oven and dry it at 100°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com