Air-entraining agent microcapsule and its preparation method

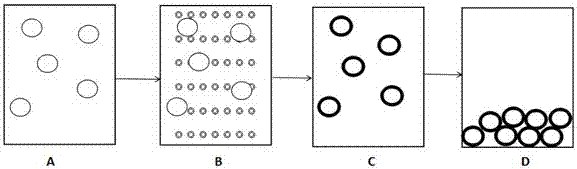

A technology of microcapsules and air-entraining agents is applied in the field of concrete admixtures, which can solve the problems of rapid disappearance of air bubbles and difficulty in achieving the performance indicators of anti-freeze-thaw concrete, and achieve the goal of improving concrete performance, increasing core competitiveness, and improving effective air bubbles. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 The preparation method of air-entraining agent microcapsules

[0026] The preparation method for concrete air-entraining agent microcapsules adopts the following steps:

[0027] (1) First, add ethyl cellulose into the beaker of ethanol solution with a mass fraction of 98%. Completely dissolve the cellulose until the solution reaches a half-saturated state, then add sodium dodecylbenzenesulfonate, wherein the mass ratio of sodium dodecylbenzenesulfonate to ethyl cellulose is 1:3, and stir.

[0028] (2) After stirring the solution obtained in step (1) continuously for 15 minutes, put the solution into a constant temperature water bath and heat it. The temperature of the constant temperature water bath is controlled at 80°C. Sodium alkylbenzene sulfonate forms a precipitate. In this step, since the boiling point of ethanol is 78.3°C, the temperature of the water bath is chosen to be 80°C, which can effectively guarantee the volatilization of ethanol without ...

Embodiment 2

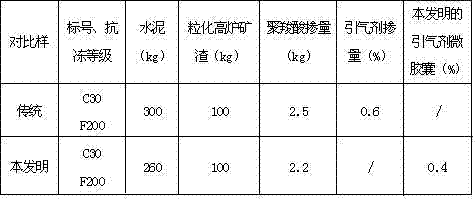

[0032] In the pouring process of the same project, the traditional method of adding air-entraining agent and the method of adding air-entraining agent microcapsules prepared in Example 1 of the present invention were used successively for comparison (see Table 1 for the amount of materials, and Table 2 for the test results) .

[0033] In order to better compare the difference between the tradition and the present invention, we adopt the main component of the air-entraining agent used in the traditional method to be selected as sodium dodecylbenzenesulfonate, and the admixture of the air-entraining agent is 1 / 2 of the total cementitious material quality of concrete. 0.6%. Traditional freeze-thaw-resistant concrete is directly mixed with air-entraining agent in the process of concrete mixing, because the air-entraining agent will release continuously in the concrete from the beginning, and because the release effect is too early, the air content of concrete will also continue to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com