Hydrophobic starch with high jetting property and preparation method thereof

A hydrophobic starch and fluidity technology, which is applied in the field of starch modification, can solve the problems that modified starch is difficult to achieve high jet flow, and the comprehensive performance of hydrophobicity and jet flow is poor, so as to improve fluidity and hydrophobicity. Comprehensive performance, the effect of no three wastes discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

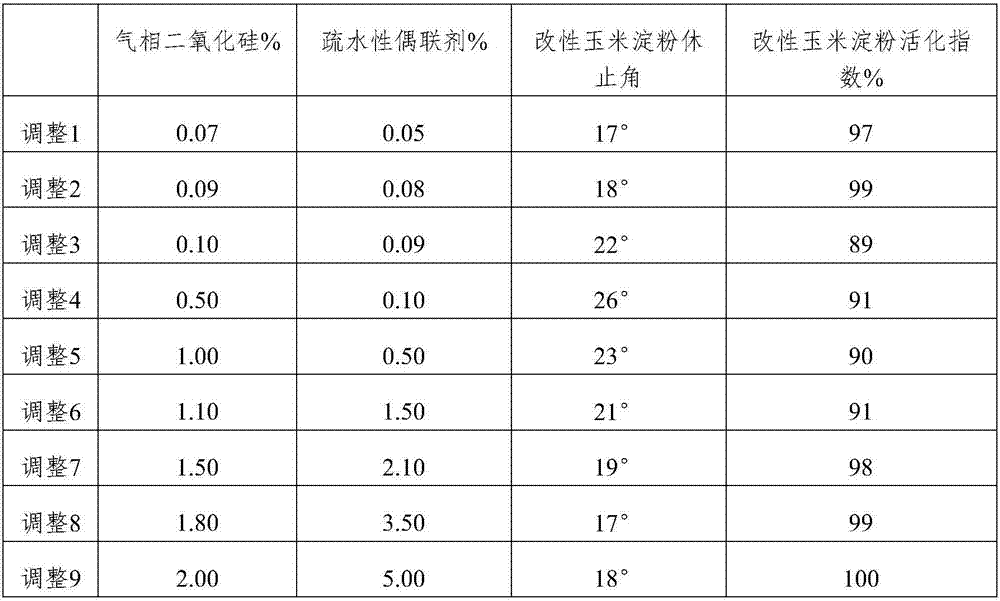

Examples

Embodiment 1

[0028] A kind of preparation method of highly spouting hydrophobic starch, comprises the following steps:

[0029] (1) Add starch into a mixer with stirring and heating functions, heat it to 75°C, and stir at a stirring speed of 1000r / min until no obvious water vapor evaporates, and add starch Mass 0.05% fumed silica, continue to stir for 20min;

[0030] (2) After the materials in step (1) are mixed evenly, and at a stirring speed of 1000r / min, add a hydrophobic coupling agent accounting for 0.5% of the starch mass, keep the temperature at 75°C, activate for 20min, and then Stirring speed is 100r / min, stirring and cooling, that is.

[0031] The starch used in this embodiment is corn starch, and the angle of repose of the dried corn starch measured according to GB 11986-1989 is 35°.

[0032] In this embodiment, the hydrophobic coupling agent is an aluminate coupling agent.

[0033] The modified corn starch obtained in this embodiment was tested for the angle of repose, and t...

Embodiment 2

[0043] A kind of preparation method of highly spouting hydrophobic starch, comprises the following steps:

[0044] (1) Add starch to a mixer with stirring and heating functions, heat to 90°C, and stir at a stirring speed of 2500r / min until no obvious water vapor evaporates, and add starch Mass 0.09% fumed silica, continue to stir for 60min;

[0045] (2) After the materials in step (1) are mixed evenly, and at a stirring speed of 2500r / min, add a hydrophobic coupling agent accounting for 1.9% of the starch mass, keep the temperature at 90°C, activate for 40min, and then Stirring speed is 500r / min, stirring and cooling, that is.

[0046] The starch that adopts is sweet potato starch;

[0047] The hydrophobic coupling agent used is a silane coupling agent;

[0048] With the sweet potato starch in embodiment 2 and the sweet potato starch after modification, with reference to the detection mode of embodiment 1, carry out the detection of angle of repose and activation index, swe...

Embodiment 3

[0050] Weigh 50kg of potato starch, add it to a mixer with stirring and heating functions, heat and stir, keep the speed at 1500r / min, adjust the temperature at 85±2°C, and dry until no obvious water vapor evaporates. After the starch is dried, add fumed silicon dioxide with a starch mass of 250 g and continue stirring for 20 min. Under the stirring condition of 1500r / min, add 550g of hydrophobic silane coupling agent KH-550 at one time, keep the temperature within the range of 85±2°C, activate it for 25min, then cool slowly under stirring at 300r / min at low speed.

[0051] With the potato starch in embodiment 3 and the modified potato starch, with reference to the detection mode of embodiment 1, carry out the detection of angle of repose and activation index, potato starch is unmodified, and its angle of repose is 36 °, and activation index is 0%, and after being treated according to the modification method of Example 3, the angle of repose is 19°, and the activation index is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com