PET (polyethylene terephthalate) composite material and preparation method thereof

A composite material and mixed material technology, applied in the field of PET composite material and its preparation, can solve the problem of low impact strength of PET material, and achieve the effects of increased hardness, environmental protection cost, and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

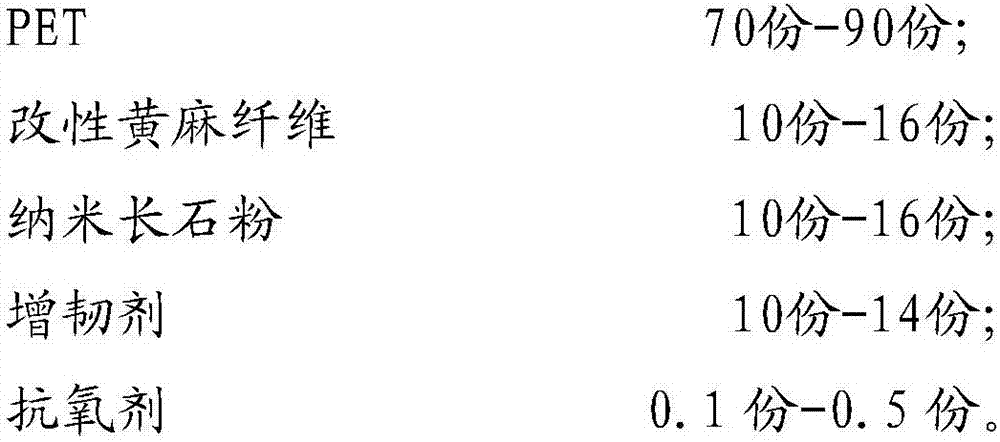

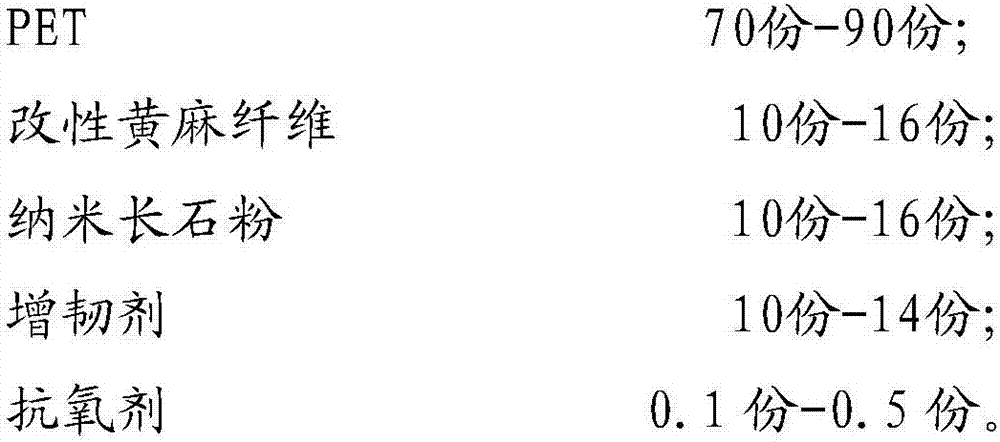

[0038] The preparation method of above-mentioned any kind of PET composite material, comprises the following steps:

[0039] (1) Weigh 70-90 parts of PET, 10-16 parts of modified jute fiber, 10-16 parts of nano-feldspar powder, 10-14 parts of binary ethylene-propylene rubber and 0.1-0.5 parts of antioxidant The agent is mixed and stirred evenly to obtain a mixture;

[0040] (2) extruding and granulating the mixture obtained in the step (1) to obtain a PET composite material.

[0041] Step (2) is specifically:

[0042] Put the mixture obtained in step (1) into the hopper of the twin-screw extruder for extrusion and granulation, wherein the twin-screw extruder includes six temperature zones arranged in sequence, and the temperature of the first zone is 240-260°C , the temperature of the second zone is 280-300°C, the temperature of the third zone is 280-300°C, the temperature of the fourth zone is 280-300°C, the temperature of the fifth zone is 280-300°C, the temperature of the...

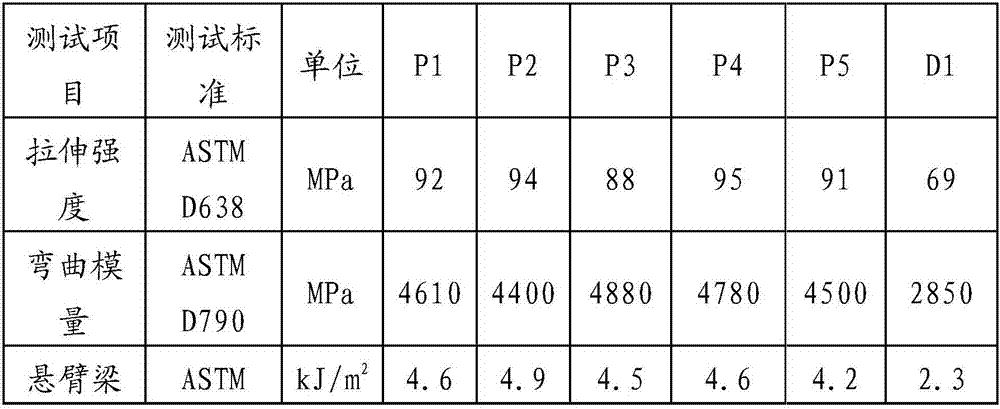

Embodiment 1

[0044] (1) take by weighing 70 parts of PET, 10 parts of modified jute fibers, 10 parts of nano feldspar powder, 10 parts of EPR, 0.1 part of Irganox168 and mix and stir to obtain a mixture;

[0045] (2) Extruding and granulating the mixture obtained in step (1) to obtain PET composite material P1.

[0046] Preferably, step (2) is specifically:

[0047] Put the mixture obtained in step (1) into the hopper of the twin-screw extruder and extrude and pelletize to obtain PET composite materials, wherein the twin-screw extruder includes six temperature zones arranged in sequence, one Zone temperature 240°C, zone 2 temperature 280°C, zone 3 temperature 280°C, zone 4 temperature 280°C, zone 5 temperature 280°C, zone 6 temperature 280°C, head temperature 280°C, screw speed 200r / min.

Embodiment 2

[0049] (1) Take by weighing 90 parts of PET, 16 parts of modified jute fiber, 16 parts of nano-feldspar powder, 14 parts of EPR, 0.1 part of Irganox168, 0.2 part of Irganox1010, 0.2 part of Irganox1330 and mix and stir to obtain a mixture;

[0050] (2) extruding and granulating the mixture obtained in the step (1) to obtain PET composite material P2.

[0051] Preferably, step (2) is specifically:

[0052] Put the mixture obtained in step (1) into the hopper of the twin-screw extruder and extrude and pelletize to obtain PET composite materials, wherein the twin-screw extruder includes six temperature zones arranged in sequence, one Zone temperature 260°C, zone 2 temperature 300°C, zone 3 temperature 300°C, zone 4 temperature 300°C, zone 5 temperature 300°C, zone 6 temperature 300°C, head temperature 300°C, screw speed 280r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com