Temperature control method for green ball drying system of rotary hearth furnace

A temperature control method and drying system technology, applied in the field of metallurgy, can solve the problems affecting drying effect, fluctuation of material volume, unstable temperature control, etc., and achieve the effect of improving production operation rate, reducing the amount of returned materials, and reducing large-scale fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

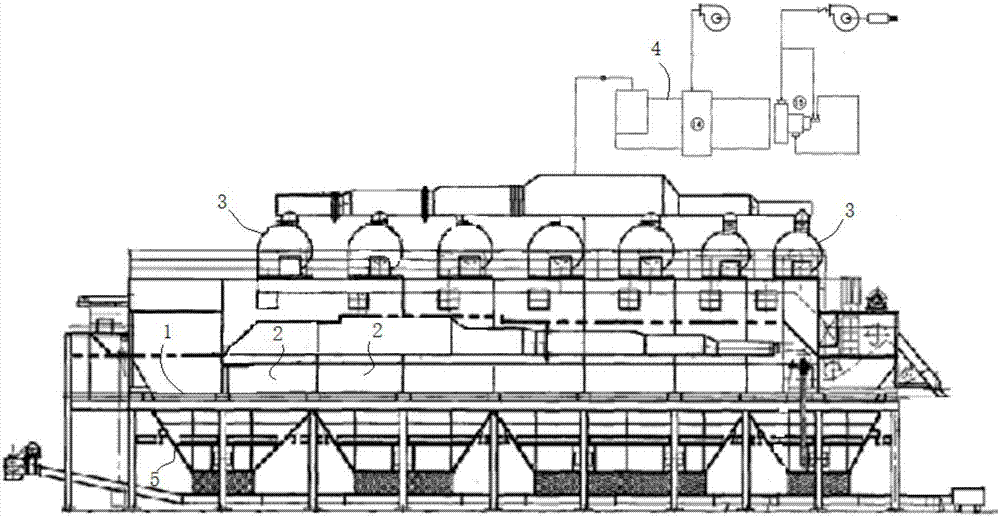

[0038] In the temperature control method of a rotary hearth furnace green pellet drying system in this embodiment, the coke oven gas pressure entering the flue gas furnace 4 is 3KPa; the coke oven gas flow rate is 1000Nm 3 / h; the air-fuel ratio in the flue gas furnace 4 is 1:0.7; the final air temperature of the flue gas furnace 4 is 300°C, and the flow rate of hot air entering the drying chamber 2 is 37000Nm 3 / h; The material surface thickness on the ball-losing net belt 1 in the drying chamber 2 is 150mm, and the speed of the ball-losing net belt 1 is 38Hz.

[0039] In this embodiment, the temperature of the 7-stage drying chamber 2 is designed intermittently by area. Specifically, along the transmission direction of the green balls, the temperatures of the 7-stage drying chamber 2 are 105°C, 125°C, 140°C, 160°C, 170°C, 180°C, 185°C, the green balls are effectively dried step by step, which not only ensures that the moisture content of the dried green balls can be reduced ...

Embodiment 2

[0053] A kind of temperature control method of the green pellet drying system of the rotary hearth furnace of the present embodiment is basically the same as the embodiment 1, the difference is that the pressure of the coke oven gas entering the flue gas furnace 4 in the present embodiment is 6KPa; the coke oven gas flow rate is 1300Nm 3 / h; the air-fuel ratio in the flue gas furnace 4 is 1:0.8; the final air temperature of the flue gas furnace 4 is 450°C, and the flow rate of hot air entering the drying chamber 2 is 37700Nm 3 / h; The material surface thickness on the ball-losing net belt 1 in the drying chamber 2 is 200mm, and the speed of the ball-losing net belt 1 is 48Hz.

[0054] Along the conveying direction of green balls, the temperatures of the seven-stage drying chamber 2 are 100°C, 120°C, 135°C, 155°C, 165°C, 175°C, and 180°C, respectively.

Embodiment 3

[0056] A kind of rotary hearth furnace green pellet drying system temperature control method of this embodiment is basically the same as embodiment 1, the difference is that the coke oven gas pressure entering the flue gas furnace 4 in the present embodiment is 5KPa; the coke oven gas flow rate is 1200Nm 3 / h; the final air temperature of the flue gas furnace 4 is 380°C, and the hot air flow rate entering the drying chamber 2 is 37500Nm 3 / h; The material surface thickness on the ball-losing net belt 1 in the drying chamber 2 is 180mm, and the speed of the ball-losing net belt 1 is 42Hz.

[0057] Along the conveying direction of green balls, the temperatures of the seven-stage drying chamber 2 are 110°C, 130°C, 145°C, 165°C, 175°C, 185°C, and 190°C, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com