Axially parallel hybrid rotor motor

A hybrid rotor and rotor motor technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit rotating parts, etc., can solve the problems of unequal internal power factor angle, insufficient mechanical strength, inconvenient installation of permanent magnets, etc., and achieve improved torque High density, high space utilization, and the effect of reducing torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

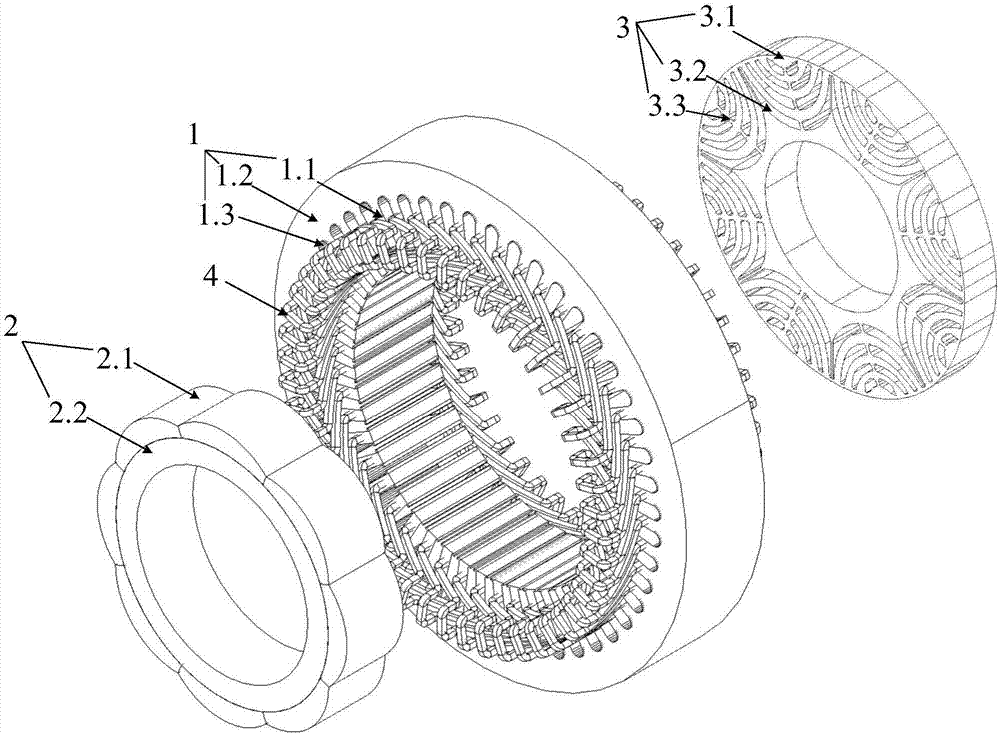

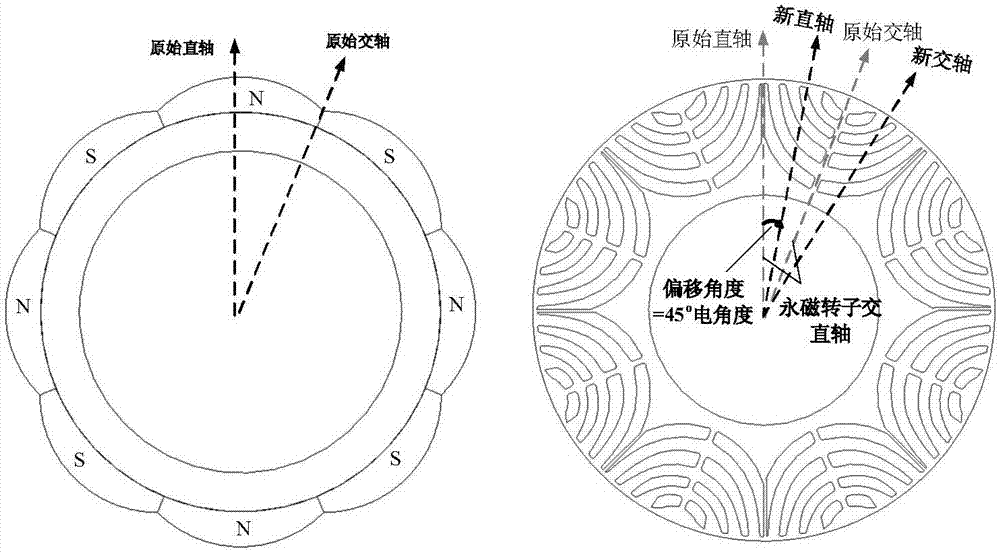

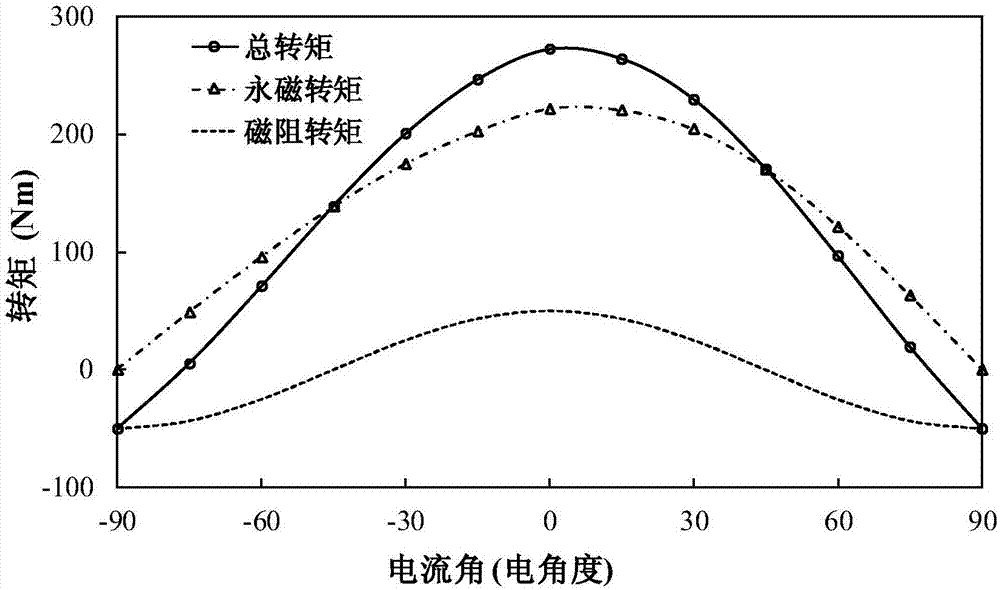

[0027] The hybrid rotor motor of this embodiment adopts a double-stage rotor parallel in the axial direction, and the two-stage hybrid rotors share a stator. Three-phase alternating current is used to drive the rotor to rotate. The direct axis of the two-stage rotor has an angular deviation, which effectively solves the problem of low utilization of the permanent magnet torque and reluctance torque components of the built-in permanent magnet motor, and further improves the torque density of the motor .

[0028] The stator 1 is arranged outside the permanent magnet rotor 2 and the reluctance rotor 3, including armature core teeth 1.1, stator yoke 1.2 and armature winding 4 arranged on the armature core teeth, and the armature core teeth 1.1 are arranged on the stator Between the yoke 1.2 and the rotor 2, a recessed space 1.3 is formed between adjacent armature core teeth 1.1, and the space 1.3 is used to place the armature winding 4 wound on the armature core tooth 1.1. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com