Coal-fired flue gas denitration and desulfurization method

A technology for coal-fired flue gas and denitrification, which is applied in separation methods, chemical instruments and methods, and air quality improvement, and can solve problems such as cumbersome operations, large floor space, and high investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

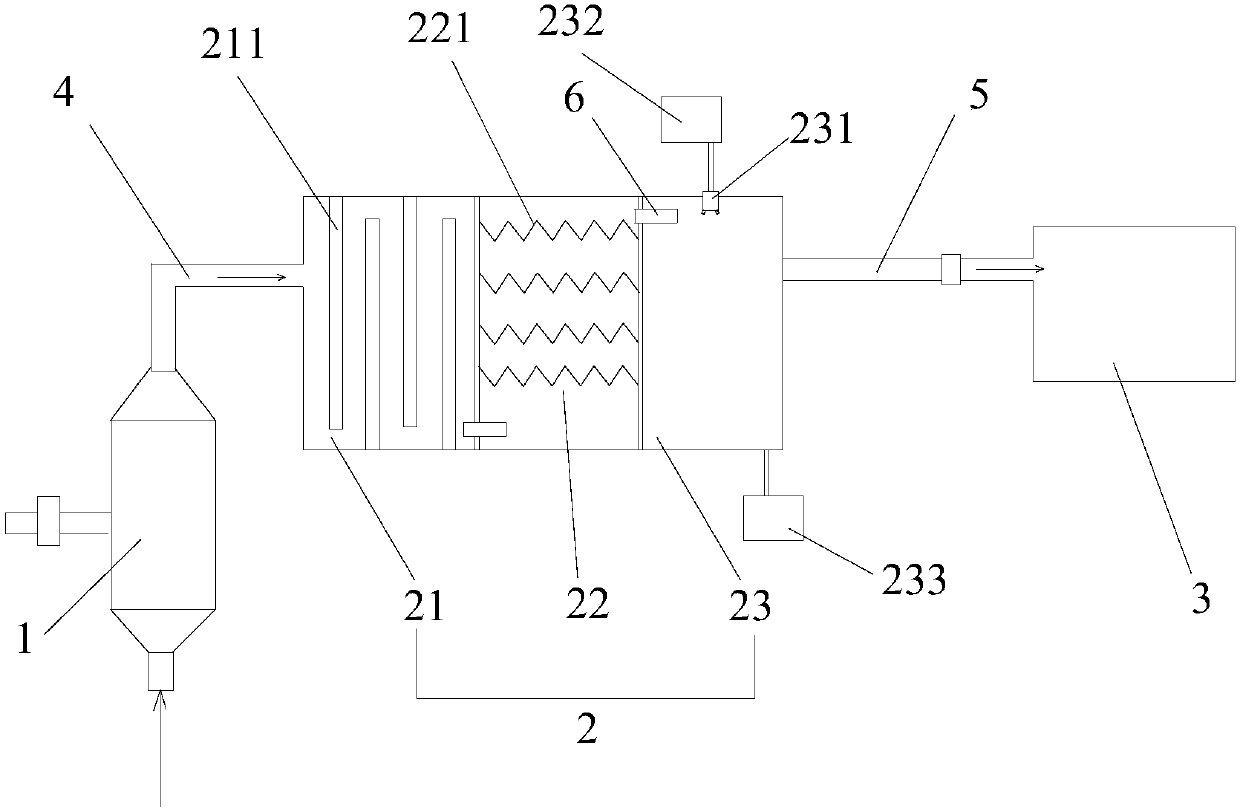

[0024] A method for denitrification and desulfurization of coal-fired flue gas provided by the present invention, the coal-fired flue gas is denitrified and desulfurized through the following steps:

[0025] 1) Pass the coal-burning flue gas into the cyclone 1 for dust removal, and remove dust particles with a particle size greater than or equal to 20um in the flue gas; the purpose is to remove more than 80% of the particle dust in the flue gas;

[0026] 2) The coal-fired flue gas after dust removal enters the desulfurization and denitrification bin 2 to react with denitrification and desulfurization agent and oxygen storage material. The weight ratio of oxygen storage material to denitrification and desulfurization agent is 1:9, and the reaction temperature is 115 °C. 2 and NO X Absorb to obtain preliminary purified flue gas;

[0027] The denitration and desulfurization agent is prepared from the following raw materials in parts by weight: 32 parts of calcium oxide, 20 parts...

Embodiment 2

[0033] A method for denitrification and desulfurization of coal-fired flue gas, wherein the coal-fired flue gas is denitrified and desulfurized through the following steps:

[0034] 1) Pass the coal-burning flue gas into the cyclone 1 for dust removal, and remove dust particles with a particle size greater than or equal to 20um in the flue gas; the purpose is to remove more than 80% of the particle dust in the flue gas;

[0035] 2) The coal-fired flue gas after dust removal enters the desulfurization and denitrification chamber 2 to react with the denitrification and desulfurization agent and the oxygen storage material. 2 and NO X Carry out adsorption to obtain preliminary purified flue gas;

[0036]The denitration and desulfurization agent is prepared from the following raw materials in parts by weight: 45 parts of calcium oxide, 28 parts of manganese dioxide, 18 parts of titanium dioxide, 18 parts of aluminum oxide, and 10 parts of seaweed;

[0037] The oxygen storage mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com