Device and method for preparing graphene from carbon material in laser shock liquid medium

A liquid medium, laser shock technology, applied in graphene, nanocarbon and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

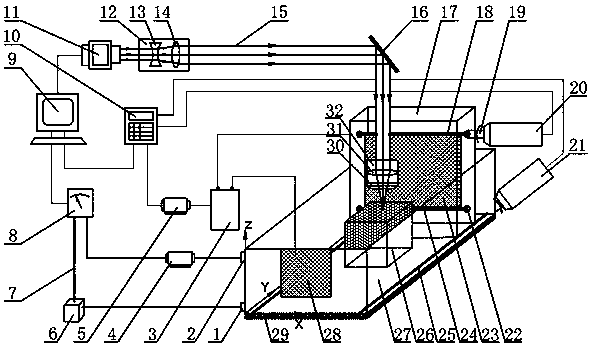

[0018] The technical solution of the present invention will be described in more detail below in conjunction with the accompanying drawings, but it is not intended to limit the present invention.

[0019] Such as figure 1 As shown, it includes a laser generating system and a reaction vessel 27 positioned below the laser generating system. Lead screws 25 in the Y-axis direction are provided on both sides of the bottom of the reaction vessel 27, and a support plate 17 is installed on the lead screws 25. The support Driven by the second motor 21, the plate 17 can move back and forth in the Y-axis direction on the lead screw 25. The support plate 17 is equipped with a second rotating shaft 24 and a first rotating shaft 18, and on the second rotating shaft 24 A copper foil 23 is wound, and a first motor 20 is installed on the first rotating shaft 18 , and the copper foil 23 moves from the second rotating shaft 24 to the first rotating shaft by the rotation of the first motor 20 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com