Oil processing wastewater treatment process and device thereof

A technology for oil processing and waste water treatment, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc. It can solve the problems of waste water treatment, waste of industrial water resources, and failure to meet production capacity increases. and other problems, to achieve the effect of stable treatment effect, saving money and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A treatment method for oil processing wastewater, using the following process.

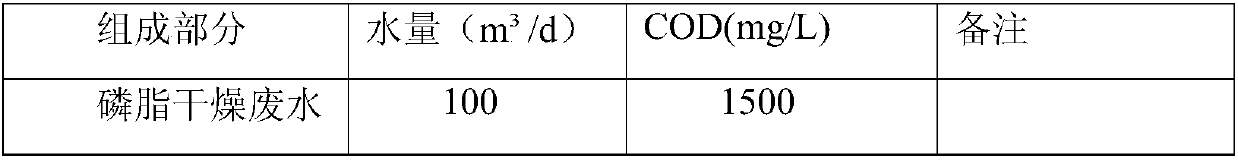

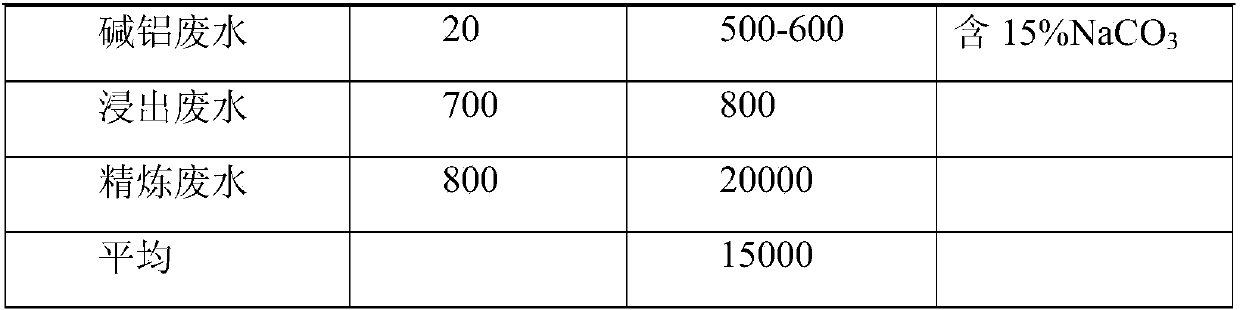

[0047] See Table 1 for wastewater conditions.

[0048] Table 1 Statistical Table of Waste Water Quality and Water Quantity

[0049]

[0050]

[0051] After testing, the COD content of the wastewater is 1500mg / L, the pH is about 9, and the SS is 250-300mg / L.

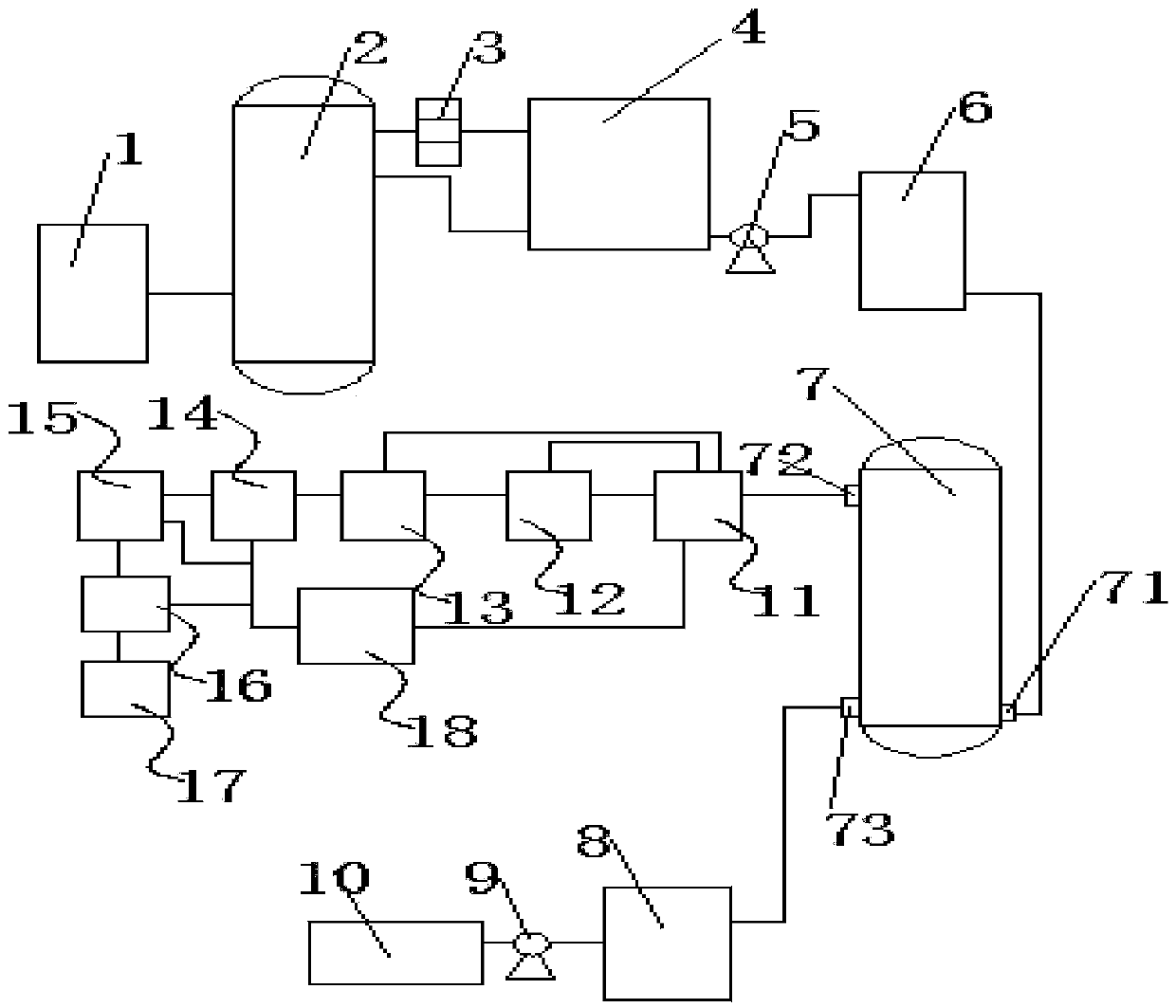

[0052] In the oil processing wastewater treatment method of the present invention, the oil wastewater is composed of: phospholipid drying wastewater, alkali aluminum wastewater, leaching wastewater, and refining wastewater. , intermediate pools, anaerobic tanks, anoxic pools, aerobic pools, secondary sedimentation tanks, biological aerated filters, sand filters, carbon filters, and clear water pools to finally obtain qualified water.

[0053] The specific process steps are as follows: including a grease wastewater treatment step and a sludge treatment step, the steps are as follows:

[0054] (1) Grease wastewater treatment ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com