A kind of modified polycarboxylate water reducing agent and preparation method thereof

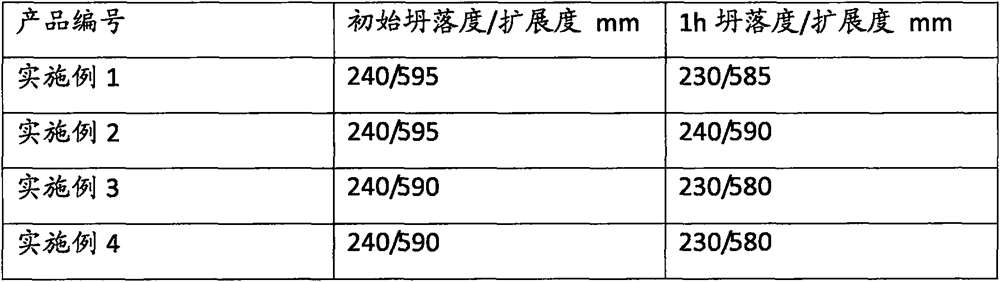

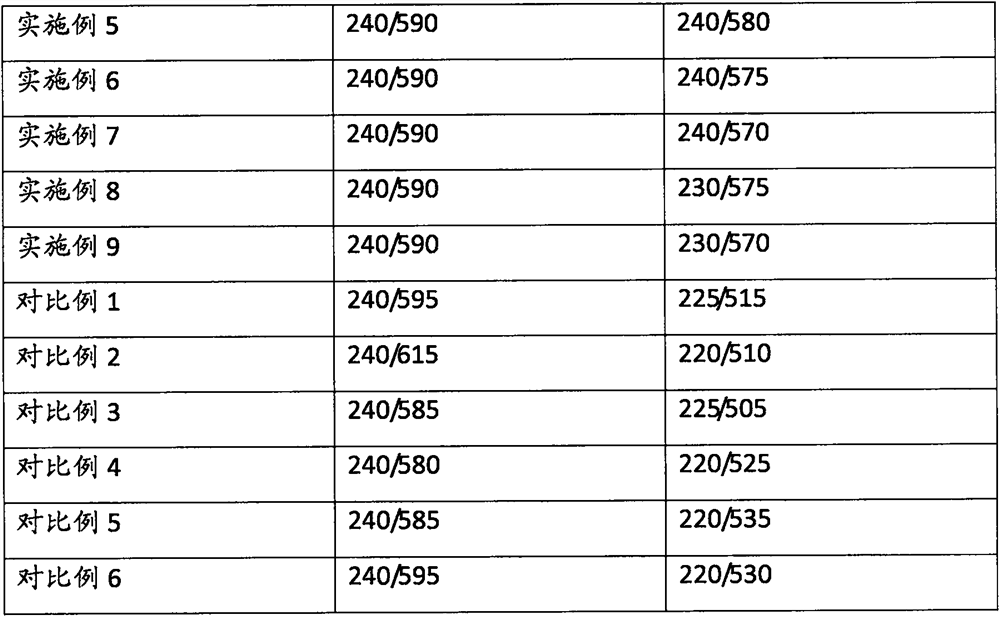

A technology of water reducer and polycarboxylate, which is applied in the field of polycarboxylate water reducer. It can solve problems such as fluctuations in work performance, and achieve the effects of good expansion and superior slump retention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add a certain amount of TPEG, modified monomer X, chain transfer agent SMAS and deionized water into a 500ml four-neck flask equipped with a stirrer, feed nitrogen gas and heat to 50°C, stir to dissolve the macromonomer completely; when the temperature rises After reaching 80°C, add AA and initiator APS dropwise at the same time, dropwise for 3 hours, and keep warm for 2 hours; after the reaction product is cooled, neutralize it with NaOH solution to obtain a modified polycarboxylate water reducer.

[0039] Wherein, the modified monomer X is The dosage of TPEG is 80g, the dosage of modified monomer X is 2g, the dosage of AA is 10g; the dosage of APS is 0.8g, and the dosage of SMAS is 0.3g.

Embodiment 2

[0041] Wherein, the modified monomer X is Others are with embodiment 1.

Embodiment 3

[0043] Wherein, the modified monomer X is Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com