Quick replacement visual positioning system for mechanical arm tool in nuclear environment and positioning method

A technology of visual positioning and positioning methods, which is applied in image analysis, instruments, calculations, etc., and can solve problems such as uncertain nature of work, uncertain working posture, and tool damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

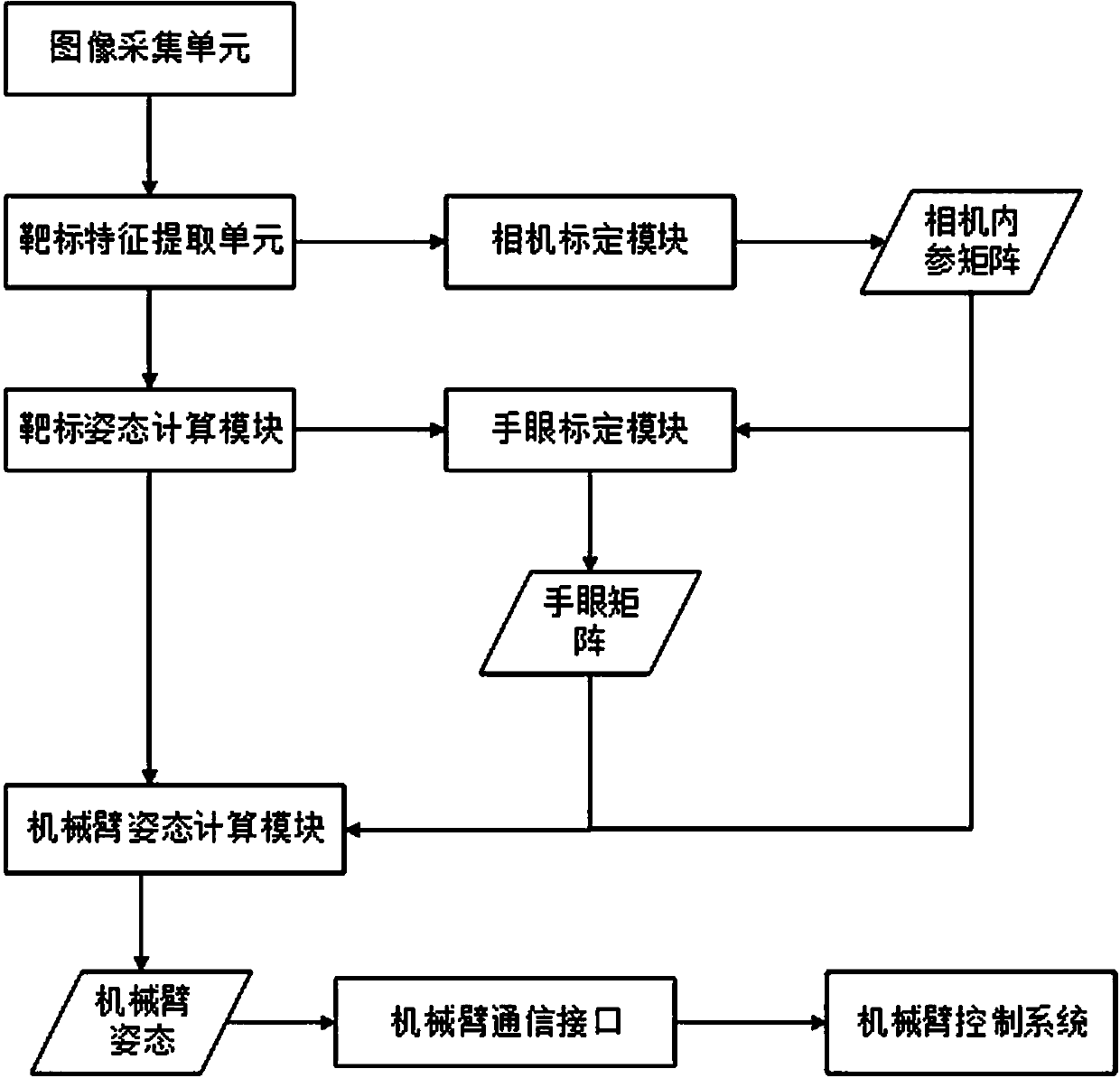

Embodiment 1

[0077] A visual positioning system for manipulator tool quick change in a nuclear environment, including an image acquisition unit, a target feature extraction unit, a target pose calculation module, a manipulator pose calculation module, and a manipulator control system that are sequentially connected by communication, and the target feature extraction unit It is also communicated with the camera calibration module, and the target pose calculation module is also connected with the hand-eye calibration module. The camera calibration module processes the feature data extracted by the target feature extraction unit through its camera internal reference matrix and sends the processing results to the hand-eye calibration module. The hand-eye calibration module combines the processing results of the camera internal reference matrix and the calculation results of the target pose calculation module for data processing and sends the processing results to the manipulator pose calculation...

Embodiment 2

[0080] A visual positioning system for manipulator tool quick change in a nuclear environment, including an image acquisition unit, a target feature extraction unit, a target pose calculation module, a manipulator pose calculation module, and a manipulator control system that are sequentially connected by communication, and the target feature extraction unit It is also communicated with the camera calibration module, and the target pose calculation module is also connected with the hand-eye calibration module. The camera calibration module processes the feature data extracted by the target feature extraction unit through its camera internal reference matrix and sends the processing results to the hand-eye calibration module. The hand-eye calibration module combines the processing results of the camera internal reference matrix and the calculation results of the target pose calculation module for data processing and sends the processing results to the manipulator attitude calcula...

Embodiment 3

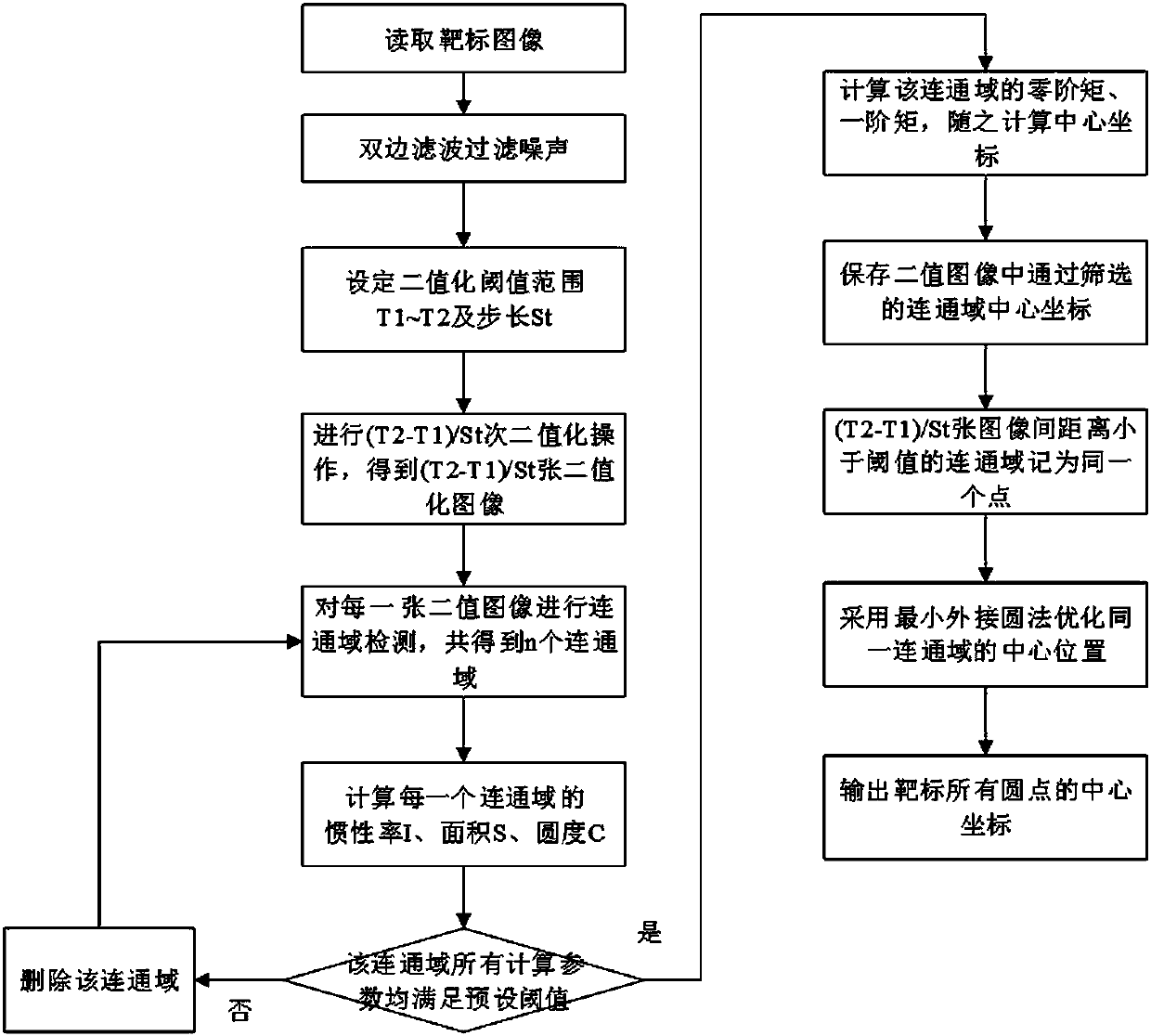

[0083] Such as Figure 1 to Figure 6 A positioning method for a tool quick change visual positioning system of a manipulator in a nuclear environment, comprising the following steps:

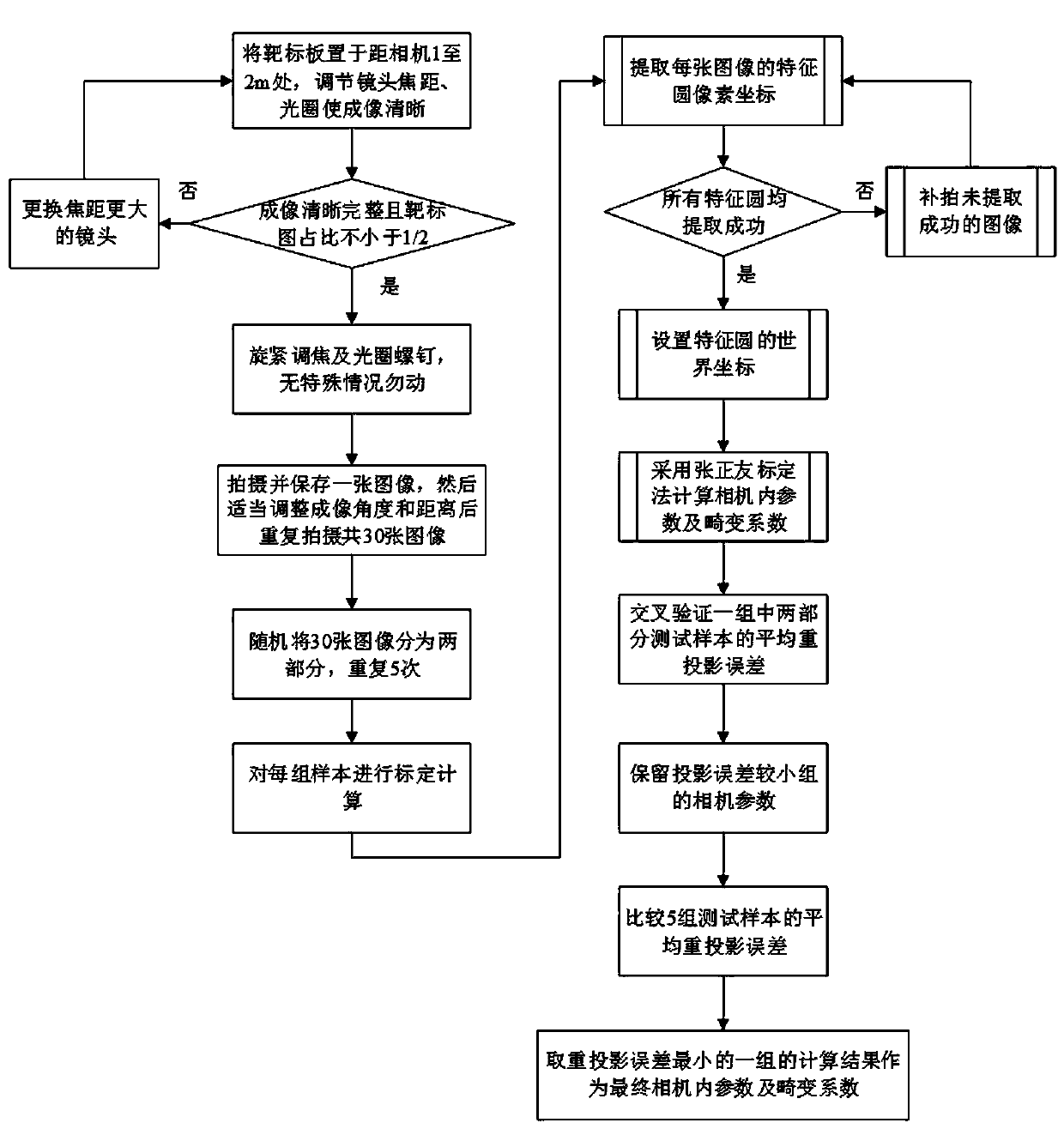

[0084] Camera calibration step, adjust the focal length and aperture of the camera until the image is clear, take a set of target images from different angles and heights, so that the target imaging covers 50% to 75% of the target image frame, and randomly divide a set of target images into two Use two groups of target images to calculate the internal parameters and distortion coefficients of the camera using the "Zhang Zhengyou calibration method" and alternately re-project to obtain the re-projection error, and keep the camera parameters calculated by the group with smaller errors;

[0085]The hand-eye calibration step of the robotic arm is to install the calibrated camera on the end bracket of the robotic arm, move the robotic arm above the target, and make the target image complete and clear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com