Proton exchange membrane, preparation method and solid high-molecular fuel cell

A proton exchange membrane and molecular sieve technology, applied in the field of proton exchange membranes, can solve the problems of decreased proton conductivity, high proton conductivity, and decreased proton conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

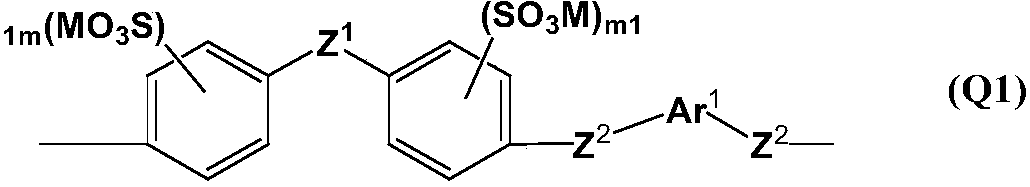

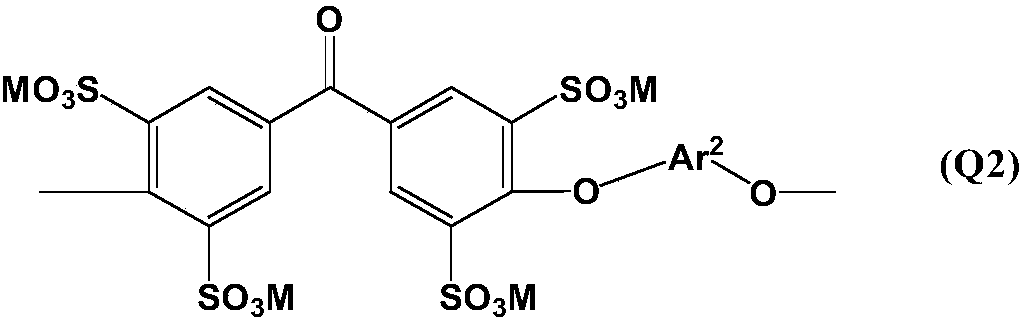

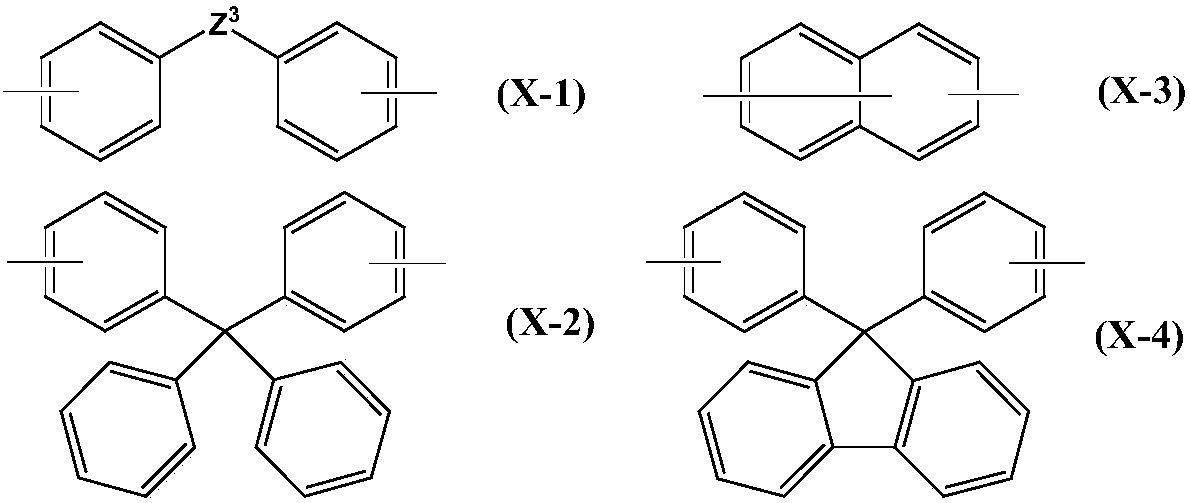

Method used

Image

Examples

Embodiment 1

[0125] 20 g of the sulfonic acid group-containing block copolymer b1 was dissolved in 80 g of N-methyl-2-pyrrolidone (NMP) to obtain a transparent solution with a solid content of 20% by weight. The obtained transparent solution was filtered under pressure using a glass fiber filter to obtain Solution 1. Take 30 g of solution 1, which contains about 6 g of sulfonic acid group-containing block copolymer b1, add 0.9 g of MCM-41 to it, and ultrasonically disperse for 30 minutes to obtain solution 2. Solution 1 was cast-coated (liquid film thickness: 50 μm) on a PET substrate, and dried at 50° C. for 0.5 hour to form the first layer of film. Solution 2 was cast-coated (liquid film thickness: 200 μm) on the dried first film, and dried at 60° C. for 1 hour to form the second film. Continue to cast solution 1 (liquid film thickness 50 μm) on the dried second film, dry at 60° C. for 1 hour, and then dry at 100° C. for 3 hours. The finally obtained membrane with a three-layer structu...

Embodiment 2

[0127] 20 g of the sulfonic acid group-containing block copolymer b1 was dissolved in 80 g of N-methyl-2-pyrrolidone (NMP) to obtain a transparent solution with a solid content of 20% by weight. The obtained transparent solution was filtered under pressure using a glass fiber filter to obtain Solution 1. Take 30 g of solution 1, which contains about 6 g of sulfonic acid group-containing block copolymer b1, add 0.9 g of MCM-41 to it, and ultrasonically disperse for 30 minutes to obtain solution 2. Solution 1 was cast-coated (liquid film thickness: 50 μm) on a PET substrate, and dried at 100° C. for 4 hours to form the first layer of film. Solution 2 was cast-coated (liquid film thickness: 200 μm) on the dried first film, and dried at 100° C. for 4 hours to form the second film. Continuously cast solution 1 (liquid film thickness: 50 μm) on the dried second film, and dry at 100° C. for 4 hours. The finally obtained membrane with a three-layer structure is immersed in 10% by we...

Embodiment 3

[0129] Except that the type and amount of silicon-based mesoporous molecular sieves are changed to 0.9g MCM-48 to obtain solution 2, the same operation as in Example 1 is used to manufacture proton exchange membrane F3 with a three-layer structure, and the performance of F3 is as shown in table 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com