Curing agent for expansible heavy metal polluted clay as well as preparation method and using method of curing agent

A heavy metal and curing agent technology, applied in chemical instruments and methods, applications, soil conditioning materials, etc., can solve the problems of lack of economical and efficient special curing agent treatment design methods, heavy metal contaminated clay is immature, and affects the improvement effect, etc., to achieve Good economic and environmental benefits, good curing effect, beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

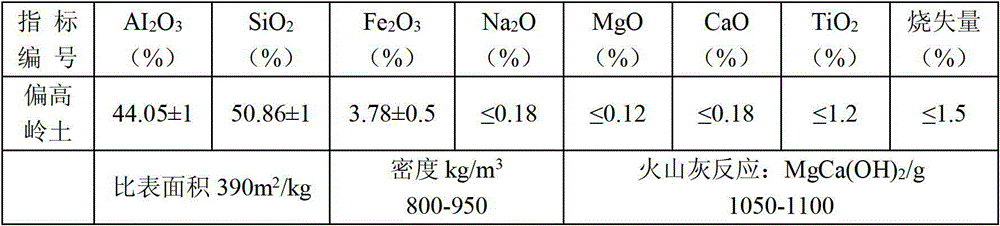

[0029] The preparation method of above-mentioned solidifying agent comprises the following steps:

[0030] Step 10): preparing modified carbide slag.

[0031] Step 10) specifically includes step 101)-step 104):

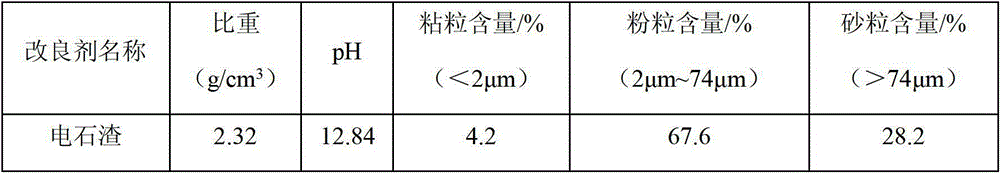

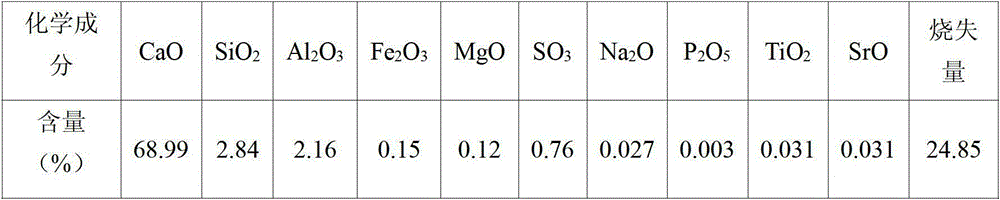

[0032] Step 101): drying the spent caustic slag so that the moisture content of the spent caustic soda slag is less than 2%, passing through a 1mm sieve, and then mixing the spent caustic soda slag with a sodium hydroxide solution with a molar concentration of 0.3-0.5mol / L according to the ratio of 1 kg of spent caustic soda slag and Mix the ratio of 1L sodium hydroxide solution, then add sodium dodecylsulfonate, stir evenly to obtain a cloudy liquid, wherein the quality of added sodium dodecylsulfonate is 1-3% of the quality of dry waste alkali residue ; Add sodium tripolyphosphate dispersant to the turbid solution, wherein the added sodium tripolyphosphate dispersant accounts for 3-5% of the quality of the dry waste alkali residue; then leave the turbid solution fo...

Embodiment 1

[0062] According to the preparation method of the present invention, the above-mentioned test materials are used to prepare the curing agent. The performance of the prepared curing agent is shown in Table 5.

[0063] The prepared curing agent was mixed with the expansive heavy metal-contaminated clay sample prepared in test material 3), and the amount of the curing agent was 3% (the curing agent accounted for the mass of the expansive heavy metal-contaminated clay sample). The water content is controlled at 18%-22%, and the three mixture soil samples that have been stirred evenly are sealed with a fresh-keeping bag and placed in a curing room at 24°C and 100% humidity for curing.

Embodiment 2

[0065] The preparation process was the same as in Example 1, except that the amount of curing agent was 4% (the curing agent accounted for the weight of the expansive heavy metal-contaminated clay sample).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com