Condensing unit for solvent recovery

A condensing device and solvent technology, which is applied in steam condensation, chemical instruments and methods, separation methods, etc., can solve the problems of solvents without buffer time, solvents prone to large temperature differences, and solvent backlogs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

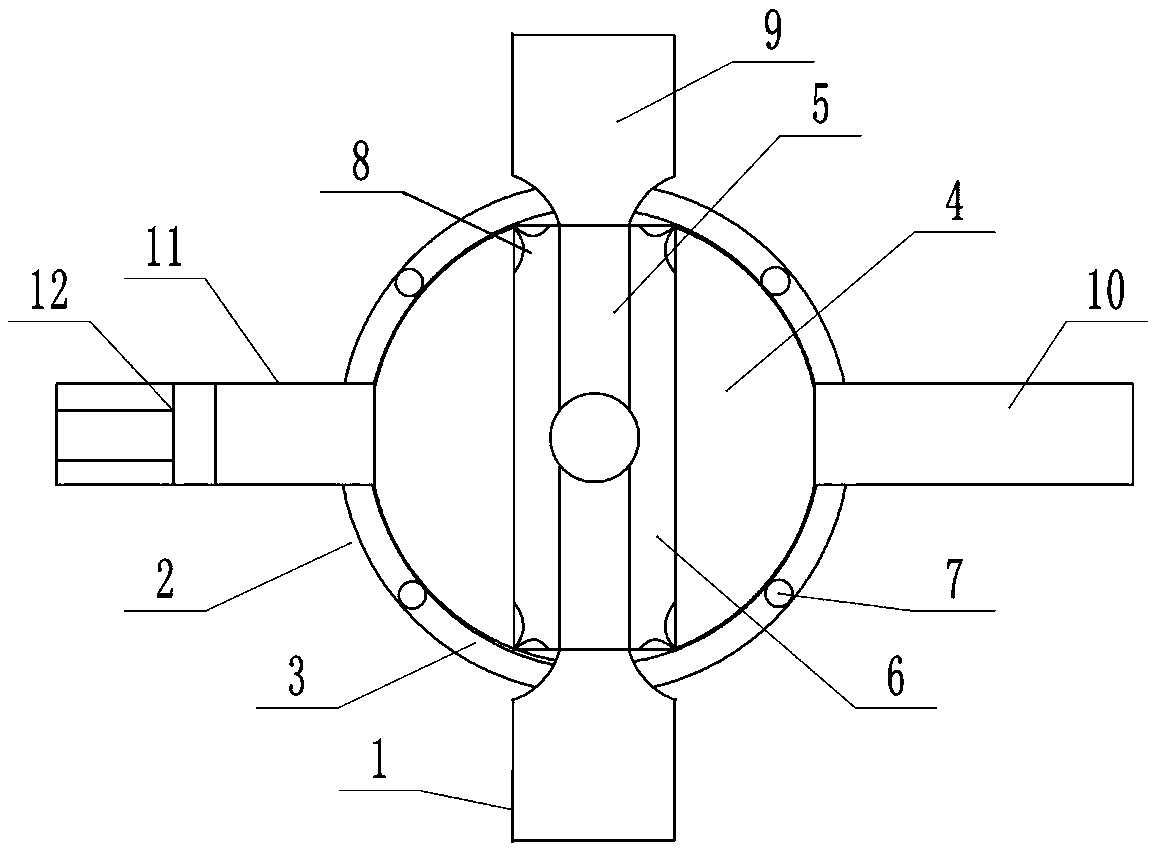

[0016] The reference signs in the drawings of the specification include: outlet pipe 1, ring 2, cooling water pipe 3, turntable 4, transfer pipe 5, condensation pipe 6, impeller 7, water exchange port 8, inlet pipe 9, storage pipe 10, booster Tube 11, piston 12.

[0017] The embodiment is basically as figure 1 Shown:

[0018] The condensing device for solvent recovery in this embodiment includes an inlet pipe 9 for the gaseous solvent that needs to be condensed and an outlet pipe 1 for the uncondensed solvent. The inlet pipe 9 and the outlet pipe 1 are fixedly connected with a ring 2, and the ring 2 A circle of concentric cooling water pipes 3 are arranged in the inner wall of the cooling water pipe 3, and several rotatable impellers 7 are arranged in the cooling water pipes 3, and the rotation direction of the impellers 7 is consistent; Take over the pipe 5, the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com