Green high-precision flexible printing corrugated carton

A flexible printing and corrugated box technology, applied in papermaking, paper coatings, rigid containers, etc., can solve the problems of non-compliance with environmental protection requirements, aggravate environmental pollution and recycling, and achieve good buffering effect, reduce vibration, and eliminate pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0025] refer to Figure 1 to Figure 2 , propose an embodiment of the green high-precision flexible printing corrugated box of the present invention:

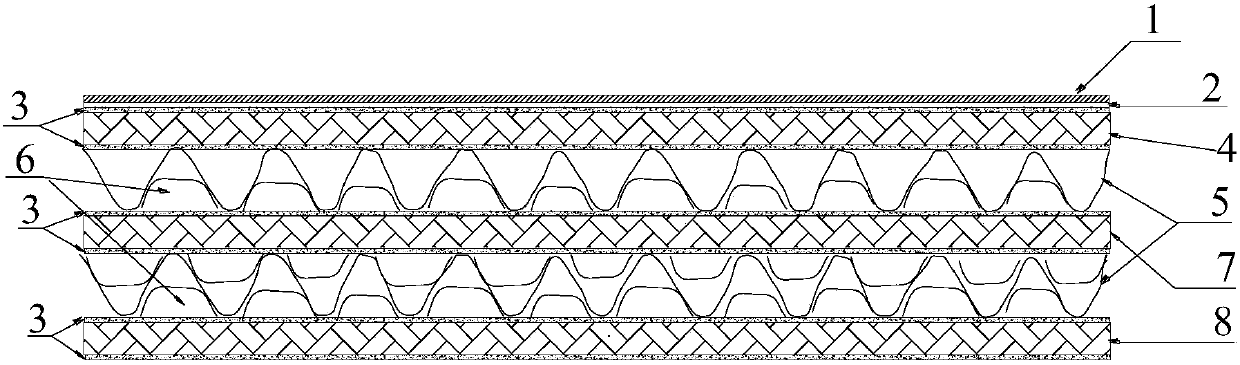

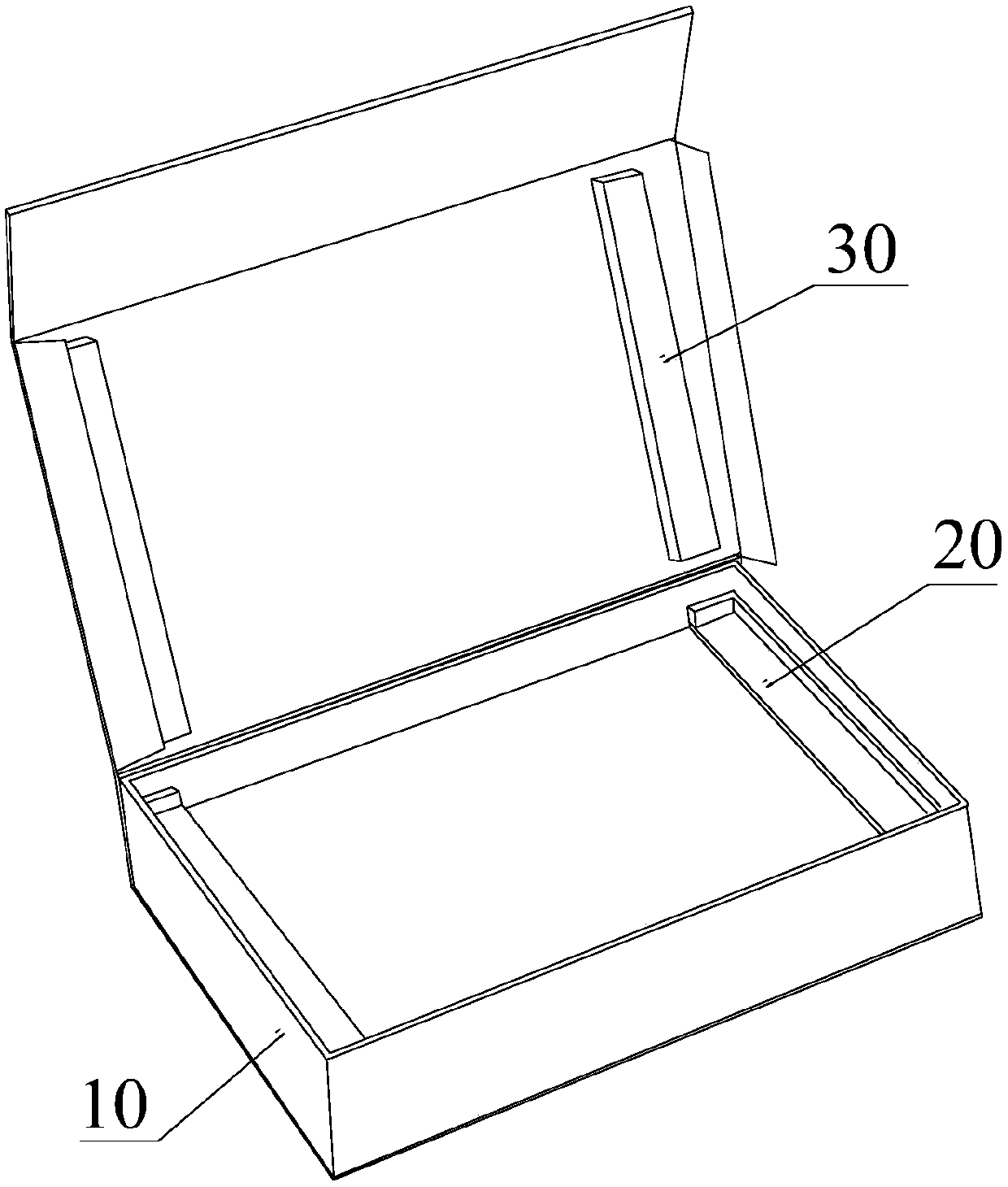

[0026] A green high-precision flexible printed corrugated cardboard box is made of corrugated boards. The box body 10 includes a box bottom plate, a front side plate, a rear side plate, a left side plate, a right side plate and a cover plate connected to the rear side plate. The boards of the bottom board, front side board, rear side board, left side board, right side board and cover board all include bottom paper 8, face paper 4 and corrugated core structure. The corrugated core structure is formed by bonding two layers of corrugated paper 5 and plane core paper 7. The plane core paper 7 is bonded between adjacent corrugated paper 5. The ribs 6 and reinforcing ribs 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com