Polycrystalline diamond superhard material and preparation method thereof

A technology for polycrystalline diamond and superhard material, which is applied in the field of polycrystalline diamond superhard material and its preparation, can solve the problems of poor phase transformation of diamond and affect the thermal stability of polycrystalline diamond material, and achieves the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

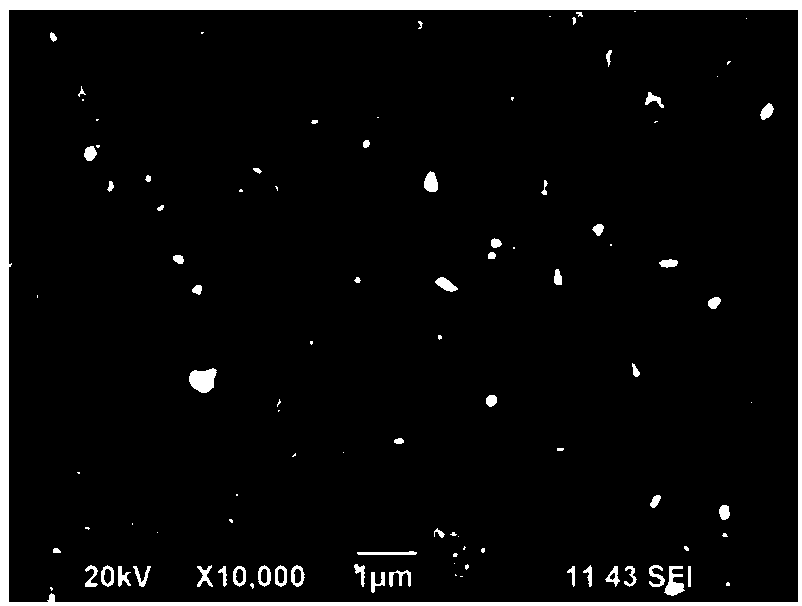

[0037] A polycrystalline diamond superhard material obtained through the following preparation process:

[0038] (1) Raw material preparation

[0039] Mix cubic boron nitride single crystal powder and diamond single crystal powder with an average particle size of 1 micron in a mass ratio of 10:90, and gently grind and mix them with a grinding rod and an appropriate amount of alcohol in a mortar After mixing for about 4 hours, dry the powder after the alcohol volatilizes, weigh 1g of the mixed raw material, put the weighed raw material powder into the metal molybdenum cup, then put the metal molybdenum cup into the mold and press the powder Pre-compression molding is carried out on the tablet machine, the applied pressure is 8MPa, the holding time is 300s, and the size of the molybdenum cup after pre-compression is Φ13*5.0 / mm;

[0040] (2) Impurity removal

[0041] Heat-treat the metal molybdenum cup containing the powder raw material that has been pre-pressed in (1) at 900°C...

Embodiment 2

[0047] (1) Raw material preparation

[0048]Cubic boron nitride single crystal powder and diamond single crystal powder with an average particle size of 0.5 microns are mixed according to a mass ratio of 20:80, and gently ground and mixed with a grinding rod and an appropriate amount of alcohol in a mortar After mixing for about 4 hours, dry the powder after the alcohol volatilizes, weigh 1g of the mixed raw material, put the weighed raw material powder into the metal molybdenum cup, then put the metal molybdenum cup into the mold and press the powder Pre-compression molding is carried out on the tablet machine, the applied pressure is 8MPa, the holding time is 300s, and the size of the molybdenum cup after pre-compression is Φ13*5.0 / mm;

[0049] (2) Impurity removal

[0050] Heat-treat the metal molybdenum cup containing the powder raw material that has been pre-pressed in (1) at 1000°C to remove impurities contained in the powder raw material;

[0051] (3) Ultra-high press...

Embodiment 3

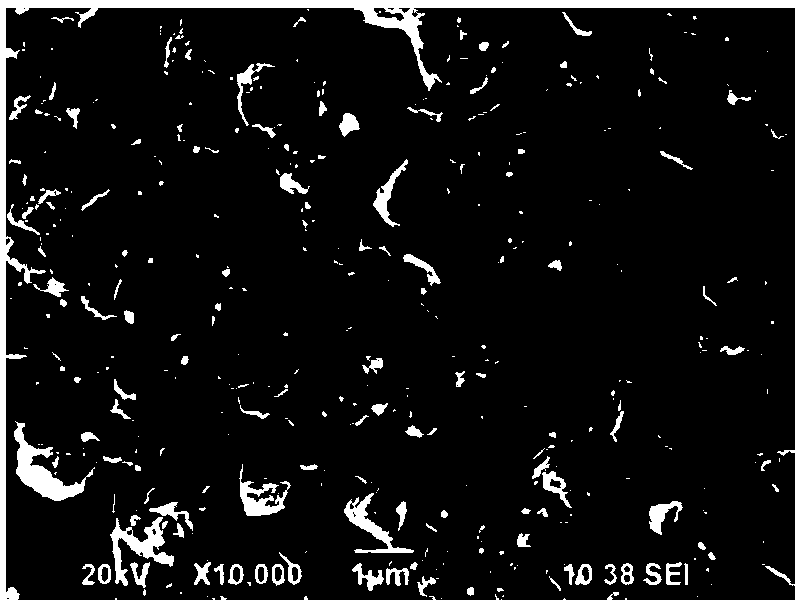

[0056] (1) Raw material preparation

[0057] Cubic boron nitride single crystal powder with an average particle size of 1 micron and diamond single crystal powder with an average particle size of 0.5 micron are mixed according to a mass ratio of 40:60, and mixed with a grinding rod in a mortar. Gently grind and mix an appropriate amount of alcohol. After mixing for about 4 hours, dry the powder after the alcohol volatilizes. Weigh 1g of the mixed raw material, put the weighed raw material powder into the metal molybdenum cup, and then put the metal molybdenum cup into the In the mold and on the powder tablet press for pre-compression molding, the applied pressure is 8MPa, the holding time is 300s, and the size of the molybdenum cup after pre-compression is Φ13*5.0 / mm;

[0058] (2) Impurity removal

[0059] Heat-treat the metal molybdenum cup containing the powder raw material that has been pre-pressed in (1) at 1000°C to remove impurities contained in the powder raw material;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com