Sea-island slice allowing low-alkaline splitting and production method of sea-island slice

A sea island and slicing technology, applied in the direction of single-component copolyester rayon, etc., can solve the problems of large caustic soda consumption, environmental damage, high cost, etc., and achieve the effects of ensuring quality, improving crystallization performance, and good hydrolysis performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

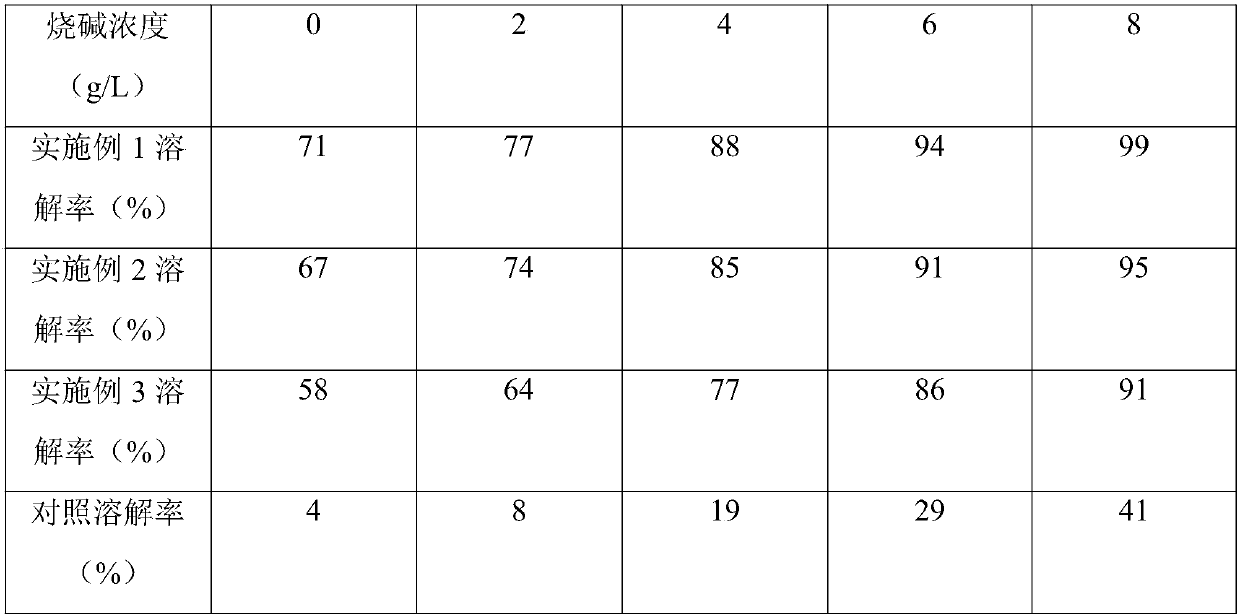

Embodiment 1

[0036] Take 55% of terephthalic acid, 24% of ethylene glycol and 7% of isophthalic acid according to the mass fraction ratio, mix them and pump them into the first esterification kettle, heat up to 255°C and keep 255±3°C for esterification reaction, the reaction In the process, the product of the first esterification tank enters the rectification tower for rectification, and a fraction is produced at the top of the rectification tower, and the esterification rate of the esterification reaction in the first esterification tank is calculated according to the mass of the fraction and the total mass of raw materials. When the esterification rate reaches 97.5%, the reaction is stopped, and the remaining reactants are pressed into the second esterification kettle with high-purity nitrogen containing less than 10 ppm of oxygen; 8% of isophthalic acid-5-sulfonate sodium is prepared into 40%wt Add the esterified solution into the second esterification tank, then take 5.98% of polyether ...

Embodiment 2

[0038] Take 56.5% of terephthalic acid, 28% of ethylene glycol and 6% of isophthalic acid according to the mass fraction ratio, mix them and pump them into the first esterification kettle, raise the temperature to 255°C and keep 255±3°C for esterification reaction. In the process, the product of the first esterification tank enters the rectification tower for rectification, and a fraction is produced at the top of the rectification tower, and the esterification rate of the esterification reaction in the first esterification tank is calculated according to the mass of the fraction and the total mass of raw materials. When the esterification rate reaches 97.5%, the reaction is stopped, and the remaining reactants are pressed into the second esterification kettle with high-purity nitrogen containing less than 10 ppm of oxygen; 4.98% of isophthalic acid-5-sodium sulfonate is prepared into 40%wt The esterification solution is added to the second esterification tank, then 4% of polye...

Embodiment 3

[0040]Take 58% of terephthalic acid, 30% of ethylene glycol and 5% of isophthalic acid according to the mass fraction ratio, mix them and pump them into the first esterification kettle, raise the temperature to 255°C and keep 255±3°C for esterification reaction. In the process, the product of the first esterification tank enters the rectification tower for rectification, and a fraction is produced at the top of the rectification tower, and the esterification rate of the esterification reaction in the first esterification tank is calculated according to the mass of the fraction and the total mass of raw materials. When the esterification rate reaches 97.5%, the reaction is stopped, and the remaining reactants are pressed into the second esterification kettle with high-purity nitrogen containing less than 10 ppm of oxygen; 2.78% of isophthalic acid-5-sodium sulfonate is prepared into 40%wt The esterification liquid is added to the second esterification tank, then 4.2% of polyethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com