Asphalt seam sealant slurry capable of adapting high temperature environment and preparation method of same

A technology of high temperature environment and seam filling glue, applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of weak adhesion performance, poor anti-aging performance, poor deformation ability, low temperature ductility, etc., to improve high temperature performance. and adhesion performance, improve high and low temperature performance, enhance the effect of anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

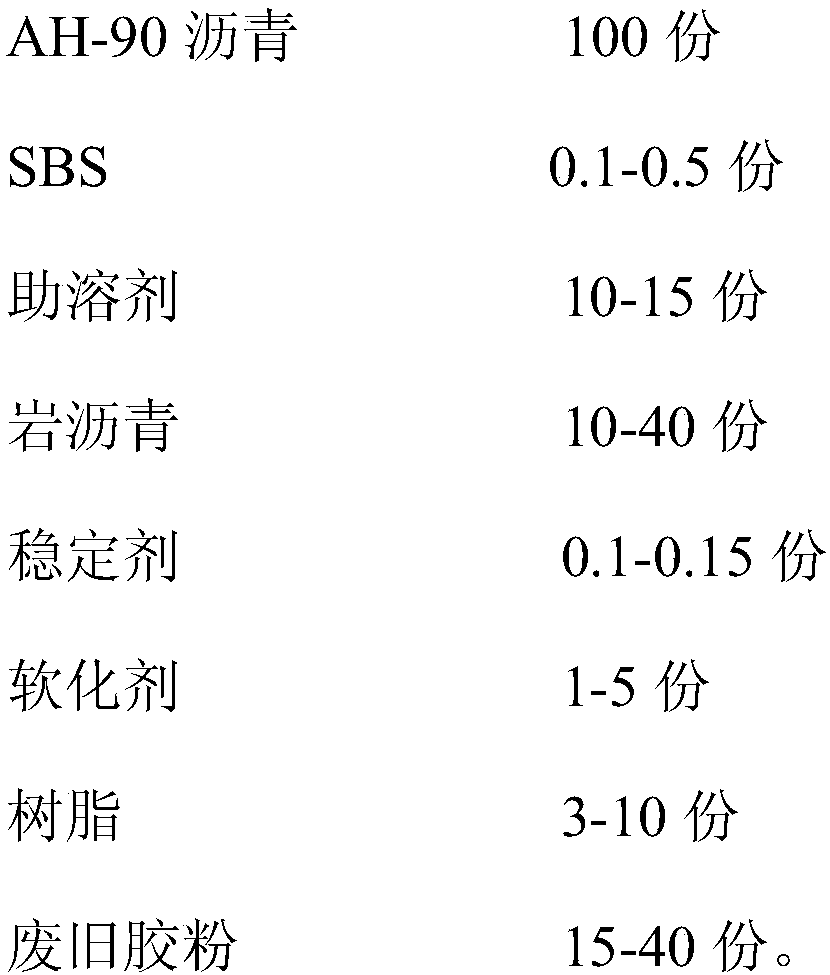

Method used

Image

Examples

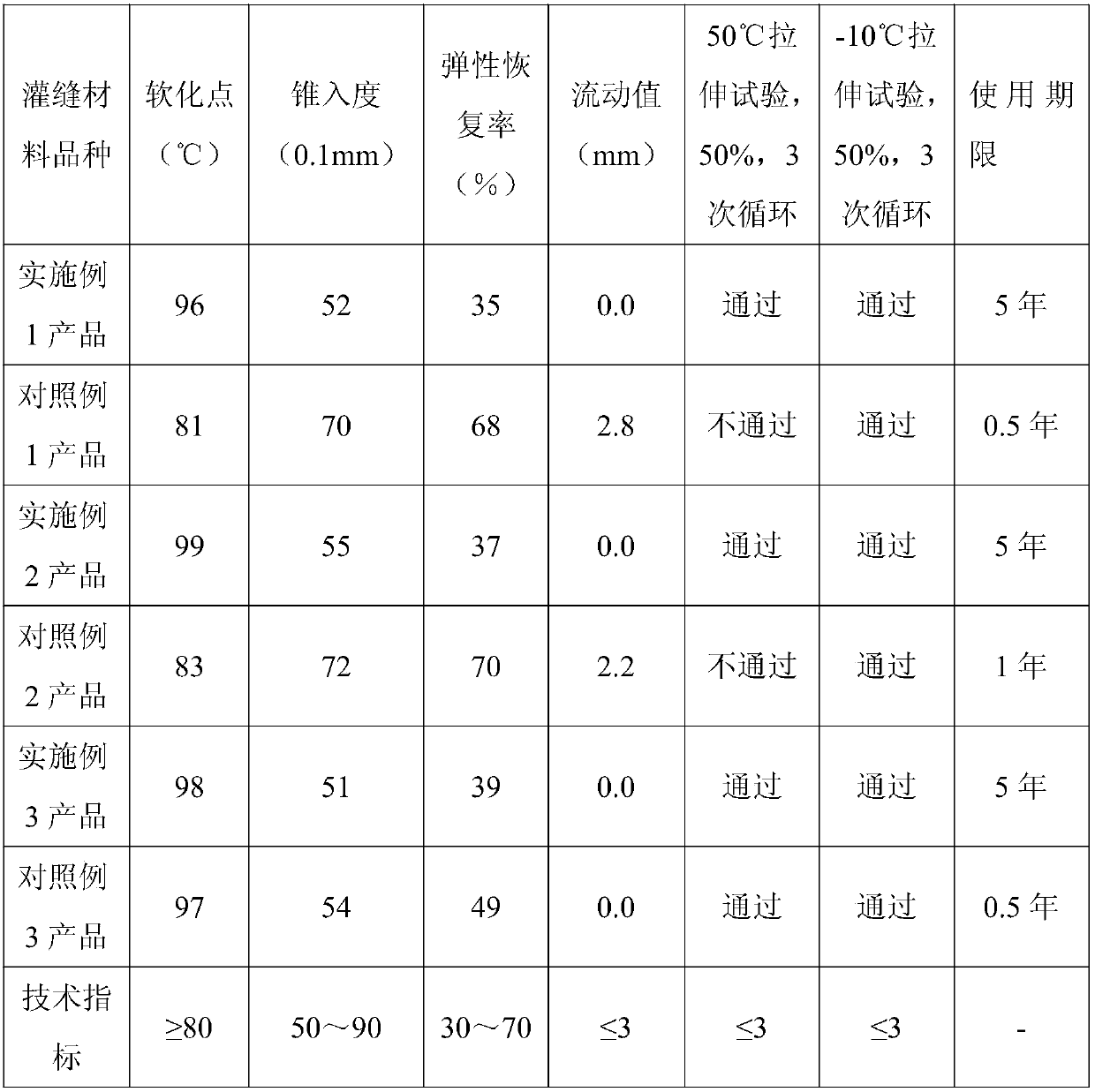

Embodiment 1

[0035] Heat 100 parts of AH-90 petroleum asphalt to a fluid state at 135°C, and when the temperature is raised to 175°C under stirring, add 0.5 parts of SBS (block ratio 20 / 80, molecular weight 300,000) and 10 parts of Co-solvent (petroleum aromatic oil), stirring for 30 minutes, then shearing for 50 minutes, and stirring again, when the process reaches 85 minutes, add 30 parts of rock asphalt (Iranian rock pitch) and 0.1 parts of stabilizer (chromic anhydride) , 3 parts of softening agent (minus second-line oil extraction), 5 parts of resin and 40 parts of waste rubber powder (100 mesh), you can get the asphalt grout suitable for high temperature environment. Wherein 30 parts of Iranian rock asphalt is added in 6 times, 5 parts each time.

Embodiment 2

[0039] Heat 100 parts of AH-90 petroleum asphalt to a fluid state at 135°C, and when the temperature is raised to 175°C under stirring, add 0.5 parts of SBS (block ratio 10 / 90, molecular weight: 400,000) and 15 parts of Co-solvent (petroleum aromatic oil), stirring for 30 minutes, then shearing for 60 minutes, and stirring again, when it is carried out to 90 minutes, add 40 parts of rock asphalt (Qingchuan rock asphalt), 0.15 parts of stabilizer (sulfurous anhydride) ), 5 parts of softener (minus the oil extracted from the third line), 3 parts of resin and 40 parts of waste rubber powder (200 mesh), you can get the asphalt grout suitable for high temperature environment. Wherein 40 parts of Qingchuan rock asphalt is added in 8 times, each 5 parts.

Embodiment 3

[0042]Heat 100 parts of AH-90 petroleum asphalt to a fluid state at 135°C, and when the temperature is raised to 175°C under stirring, add 0.5 parts of SBS (block ratio 10 / 90, molecular weight: 400,000) and 12 parts of Co-solvent (petroleum aromatic hydrocarbon oil), stirring for 30 minutes, then shearing for 55 minutes, and stirring again, when it was carried out to 80 minutes, 30 parts of rock asphalt (buton rock asphalt), 0.1 part of stabilizer (acetic anhydride ), 4 parts of softener (minus the oil extracted from the third line), 5 parts of resin and 20 parts of waste rubber powder (80 mesh), you can get the asphalt grout suitable for high temperature environment. Wherein 30 parts of Buton rock asphalt was added in 6 times, 5 parts each time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com