Special oil composition for gear hobbing machine and application of special oil composition

A technology of special oil and composition, applied in lubricating composition, petroleum industry, etc., which can solve problems such as unsatisfactory tool protection, poor hydraulic system compatibility, and insufficient lubricating performance of oil products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

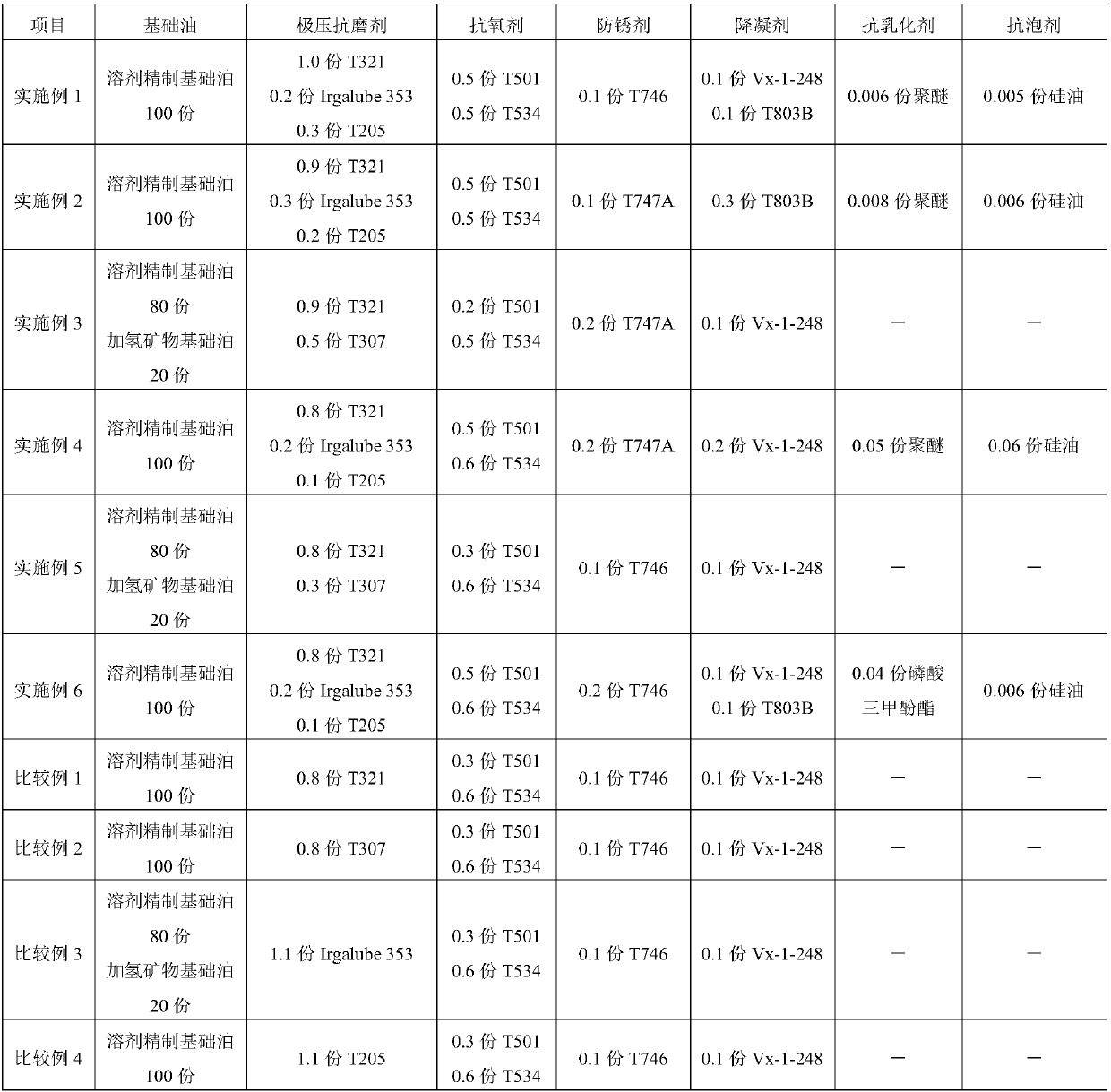

[0031] According to the parts by weight in Table 1, take the required amount of pour point depressant, antirust agent, antioxidant, demulsifier, antifoaming agent and add them to the base oil (viscosity grade is 32, 46, 68) respectively, Heat and stir at 70°C until completely uniform, then lower the temperature to 60°C, add extreme pressure antiwear agent, stir until completely uniform to obtain the special oil composition for gear hobbing machines. The type and amount of each component in the composition are specifically shown in Table 1.

[0032] Among them, T321 is a sulfurized olefin; T307 is a phosphorothioate double ester amine salt; Irgalube 353 is a phosphorothioate; T205 is a zinc dialkyl dithiophosphate derivative; T501 is 2,6-di-tert-butyl p-methyl T534 is alkylated diphenylamine; T746 is alkenyl succinate; T747A is alkenyl succinate half ester; Vx-1-248 is polymethacrylate; T803B is polyalphaolefin; T921 is acrylic acid Ester and ether copolymer.

Embodiment 7

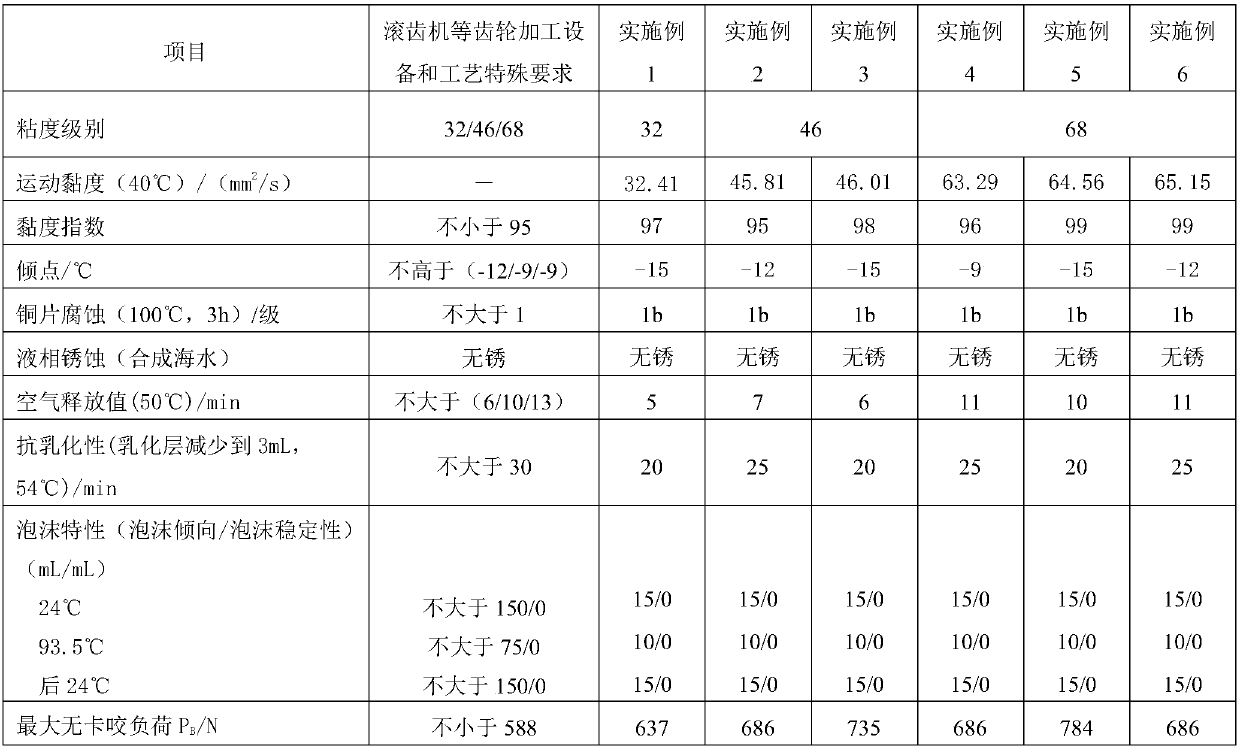

[0034] For the extreme pressure and wear resistance (maximum non-seizing load PB) of the compositions in [Examples 1 to 6], compatibility with hydraulic systems of gear processing machine tools such as gear hobbing machines (viscosity index, pour point, copper sheet corrosion, Liquid phase corrosion, air release value, foam characteristics, anti-emulsification performance) were tested, and the test results are shown in Table 2.

Embodiment 5

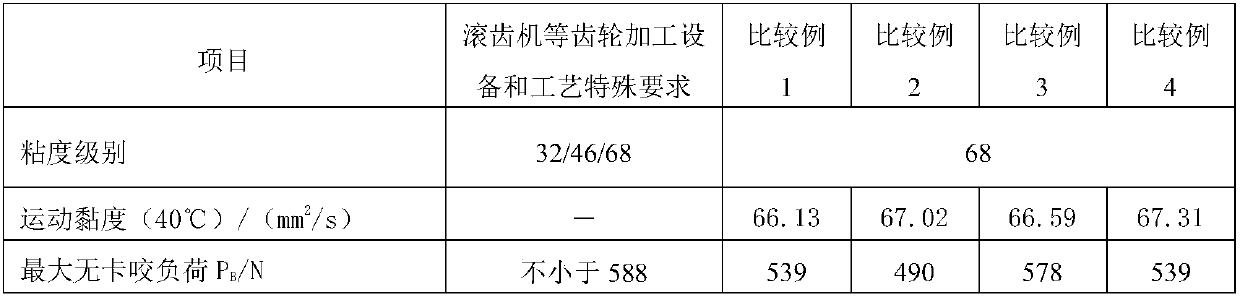

[0035] Extreme pressure and anti-wear properties are one of the most important properties of special oils for gear hobbing machines. For each composition in [Examples 1-6], the maximum non-seize load PB index was tested. The larger the maximum non-jamming load PB value, the better the extreme pressure and anti-wear performance of the special oil for gear hobbing machines. [Examples 1-6] Among the extreme pressure and anti-wear properties of each composition, the maximum non-seizing load P B The values are all greater than 588N, indicating that each composition can meet the special requirements of gear hobbing and other processing techniques. In comparison, the maximum non-jamming load PB value of each combination is as follows: [Example 5] > [Example 3] > [Example 2] = [Example 4] = [Example 6] > [Example 1】. Therefore, based on the above evaluation of the extreme pressure and anti-wear performance of special oil for gear hobbing machine, the maximum non-jamming load P B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com