An adjustable anti-splash broadband laser cladding coaxial powder feeding nozzle and its manufacturing method

A technology of laser cladding and coaxial powder feeding, applied in metal material coating process, coating and other directions, can solve the problem of damage to the protective mirror lens of the laser processing head, lack of anti-spatter function of processing molten pool slag, and powder feeding. The cooling water channel of the seat cannot be processed, etc., to achieve obvious powder blowing effect, improve powder utilization rate, and good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

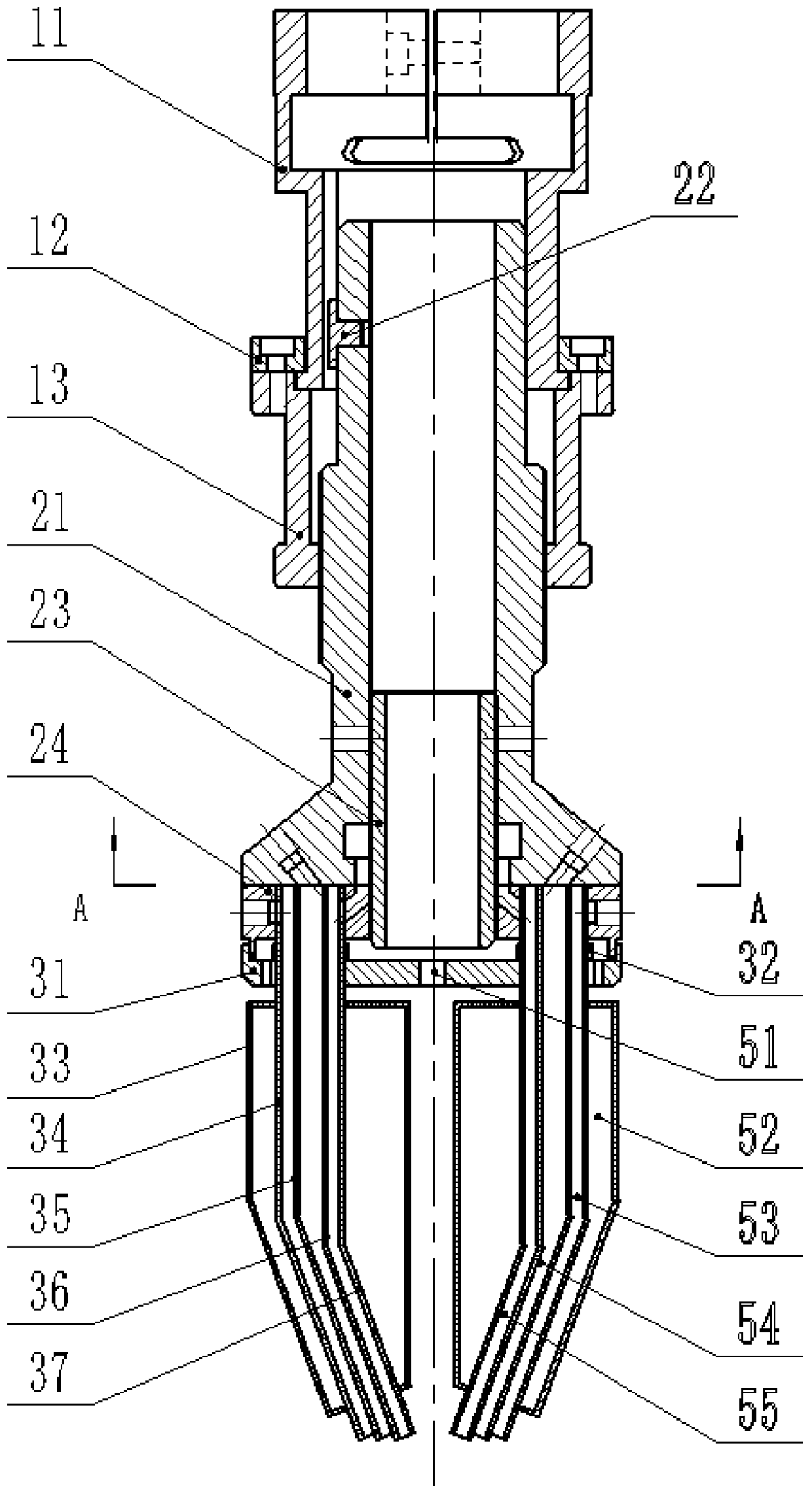

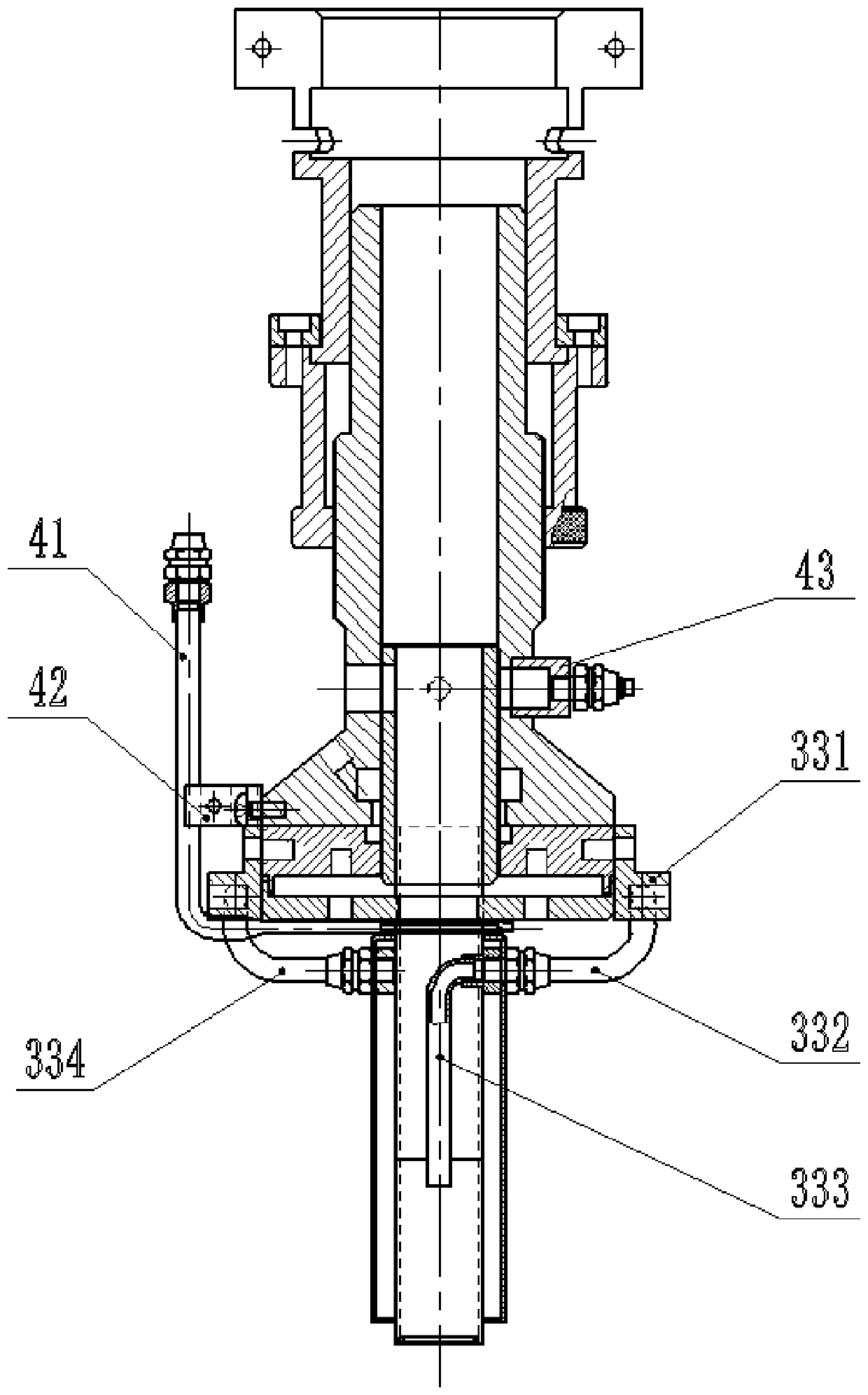

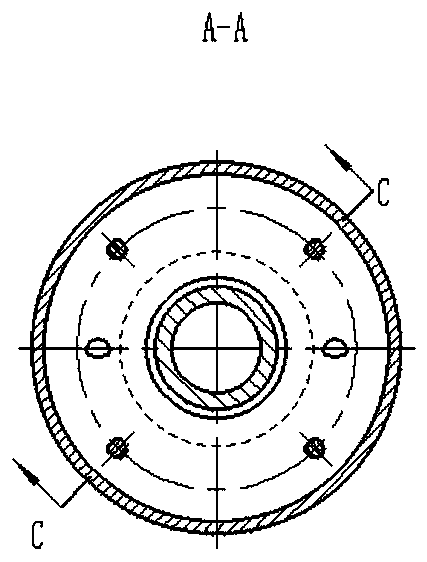

[0041] Such as figure 1 and figure 2As shown, an adjustable anti-splash broadband laser cladding coaxial powder feeding nozzle includes an upper body, an intermediate body, a lower body and an air blowing mechanism; the upper body includes a pressure ring 12 and a connecting hoop 11 with a central hole and an adjustment Nut 13, the upper part of the connecting hoop 11 is a hoop structure connected with the laser processing head, the middle part is provided with an axial groove, and the lower part is provided with a flange, and the flange is located in the top sinking platform of the adjusting nut 13. The pressure ring 12 is cut into left and right halves, which is convenient for assembly) and fixed on the adjusting nut 13 (the pressure ring 12 is connected with the adjusting nut 13 through six uniformly distributed screws) to limit the axial position ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com