Composite material pile-anchor supporting method

A composite material, pile anchor technology, applied in excavation, sheet pile walls, construction, etc., can solve the problems of speeding up construction progress, waste of environmental pollution, non-reusable, etc., to reduce stress concentration, reduce operation and maintenance costs, and production costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

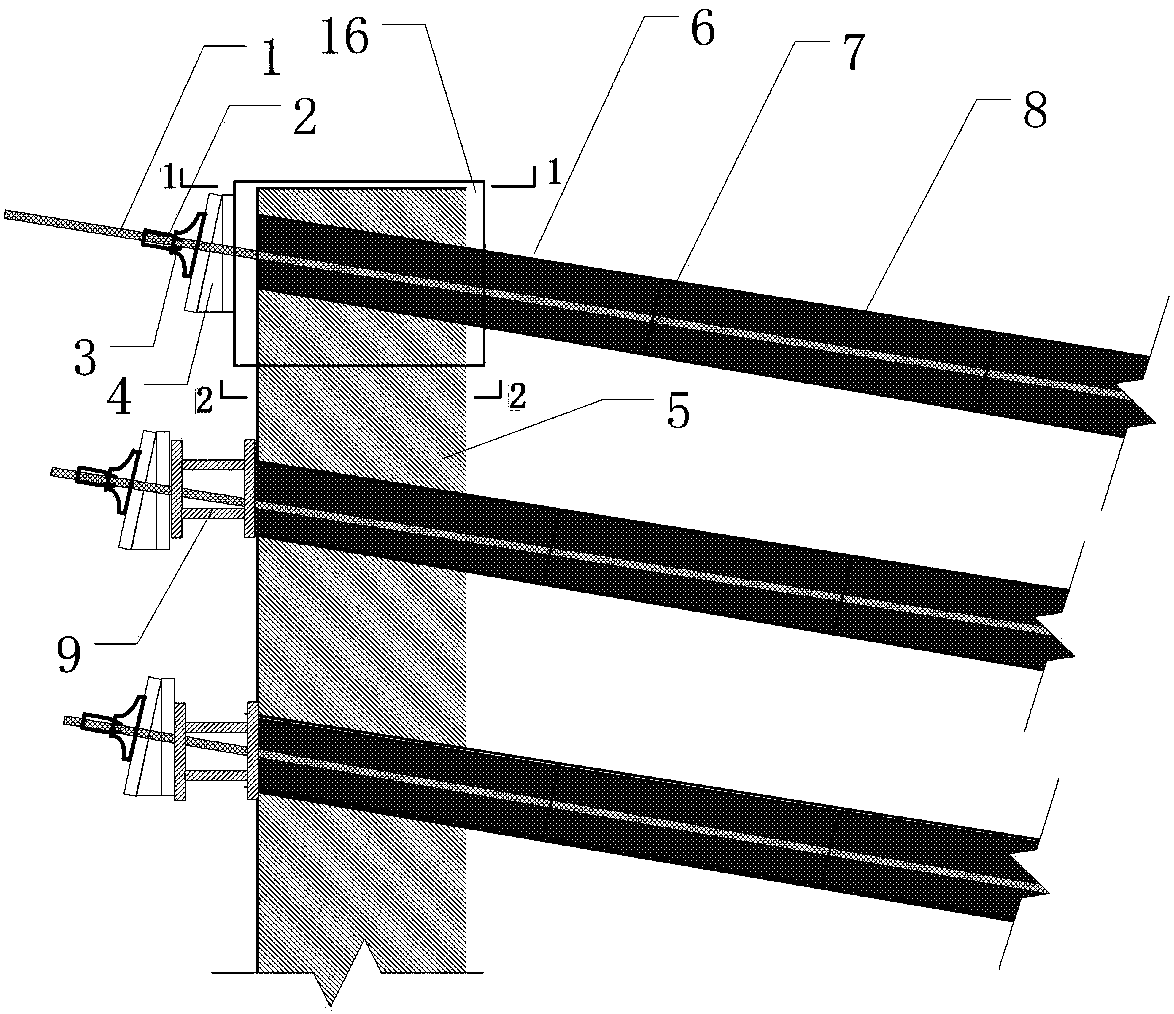

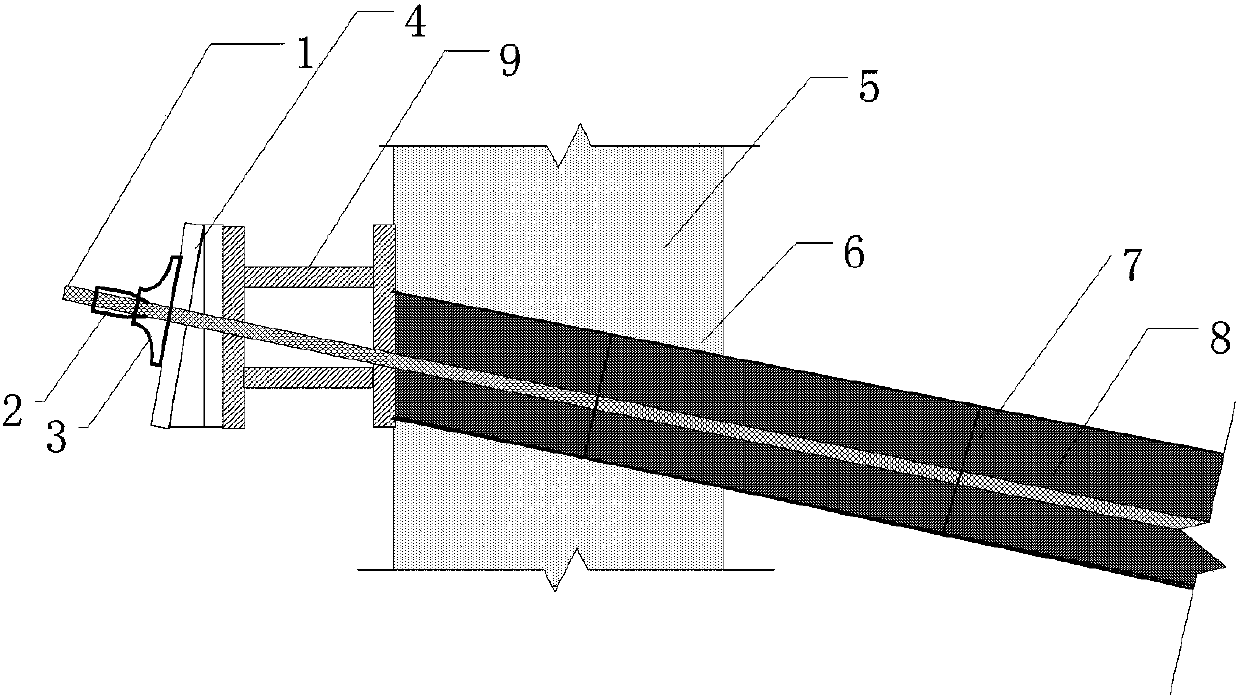

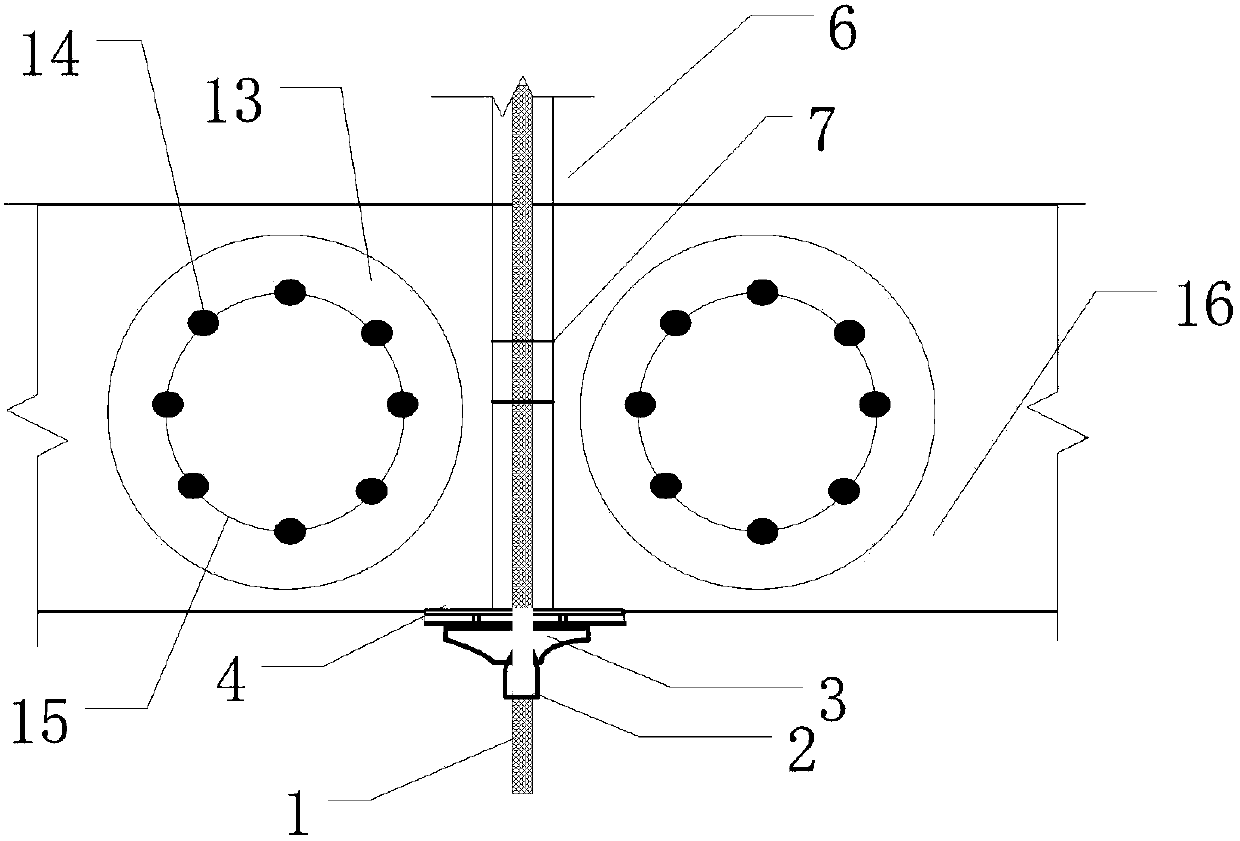

[0028] This embodiment adopts composite material pile-anchor support device to realize, and its specific process is:

[0029] (1) Bind the main reinforcement 14 and the spiral stirrup 15 into a reinforcement cage according to the actual design requirements. When binding, the spiral reinforcement 15 is wound around the main reinforcement 14 and bound and fixed with binding wire at the intersection, and the reinforcement cage is put into the pre-set perfusion Concrete is poured into the pile holes to make cast-in-place piles 13. The cast-in-place piles 13 are constructed with pile intervals, and the pile construction is carried out 24 hours after pouring the concrete; the curing time for the cast-in-situ piles 13 to reach the design requirements is 28 days, or the pile body concrete When the strength reaches 75% of the designed compressive strength, a crown beam 16 is constructed at the pile head position of the cast-in-place pile 13, and holes are reserved during the constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com