Oil transportation pipeline with corrosion-prevention function

A technology for transporting pipelines and petroleum, which is applied in pipeline protection, pipeline heating/cooling, and pipeline protection through heat insulation. Improved convenience and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

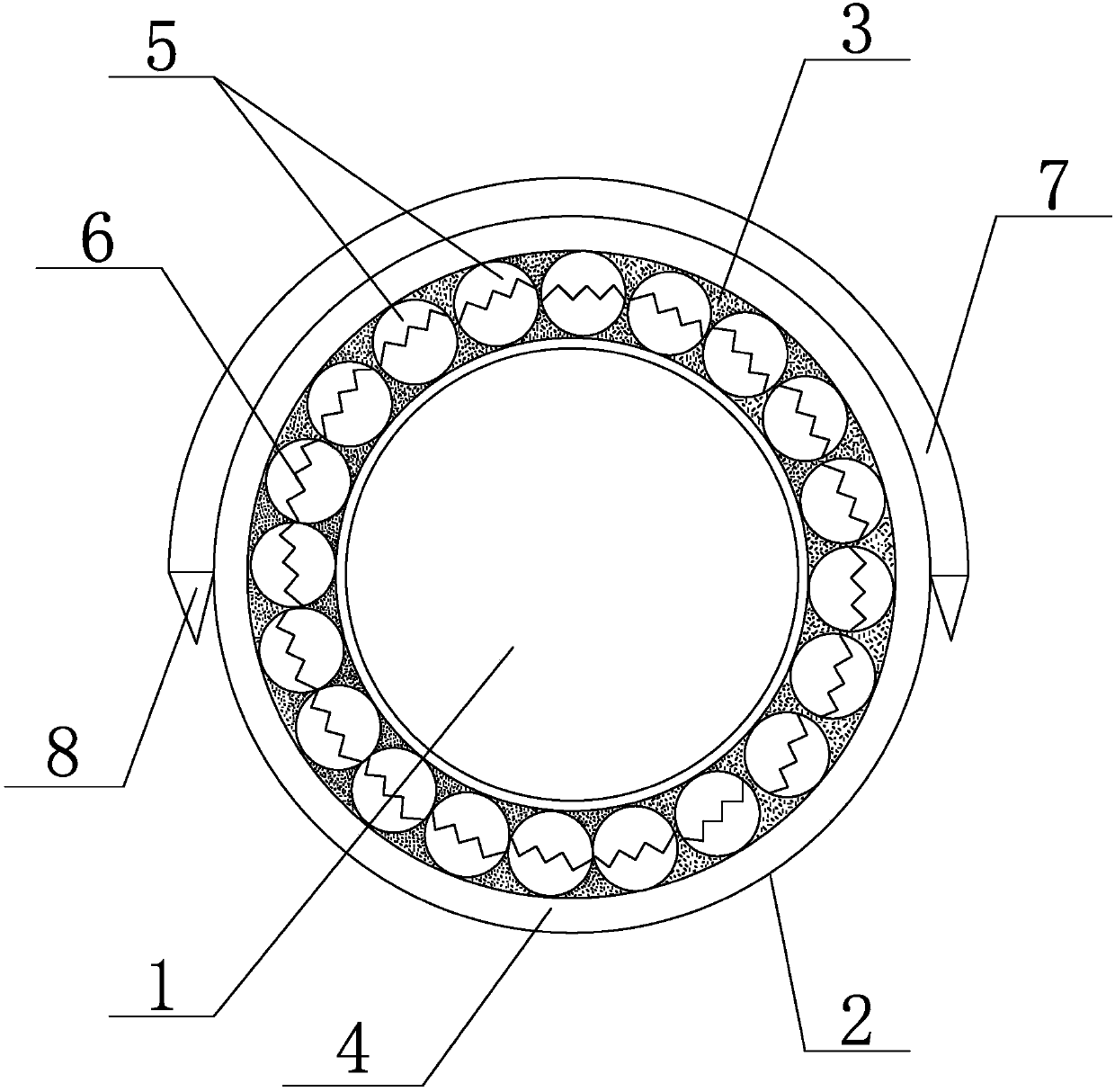

[0022] Such as figure 1 As shown, the oil transportation pipeline with anti-corrosion function of the present invention includes an inner pipeline 1 and an outer pipeline 2 sleeved outside the inner pipeline 1, and an insulating layer 3 and Anti-corrosion layer 4, the thermal insulation layer 3 is provided with a plurality of thermal insulation pipes 5 whose axes are parallel to the axis of the inner pipeline 1 along the circumferential direction of the inner pipeline 1. 5 is provided with a sawtooth-shaped partition plate 6, which is located at the axis of the heat preservation pipe 5 and divides the heat preservation pipe 5 into two cavities close to the inner pipe 1 and away from the inner pipe 1, and close to the inner pipe 1 The cavity of the inner pipe 1 is filled with foam, and the cavity far away from the inner pipe 1 is filled with desiccant; the upper outer wall of the outer pipe 2 is sequentially provided with a plurality of semi-circular drainage rings 7 along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com