Spiral pipe membrane wall hearth and application thereof

A spiral coil and membrane technology, applied in the field of spiral coil membrane fireplace hearth, can solve the problems of increasing installation workload, reducing heat exchange efficiency, and large amount of deformation of straight tube membrane wall due to thermal expansion and cold contraction , to achieve the effect of reducing installation workload, improving heat exchange efficiency, and unique flow mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

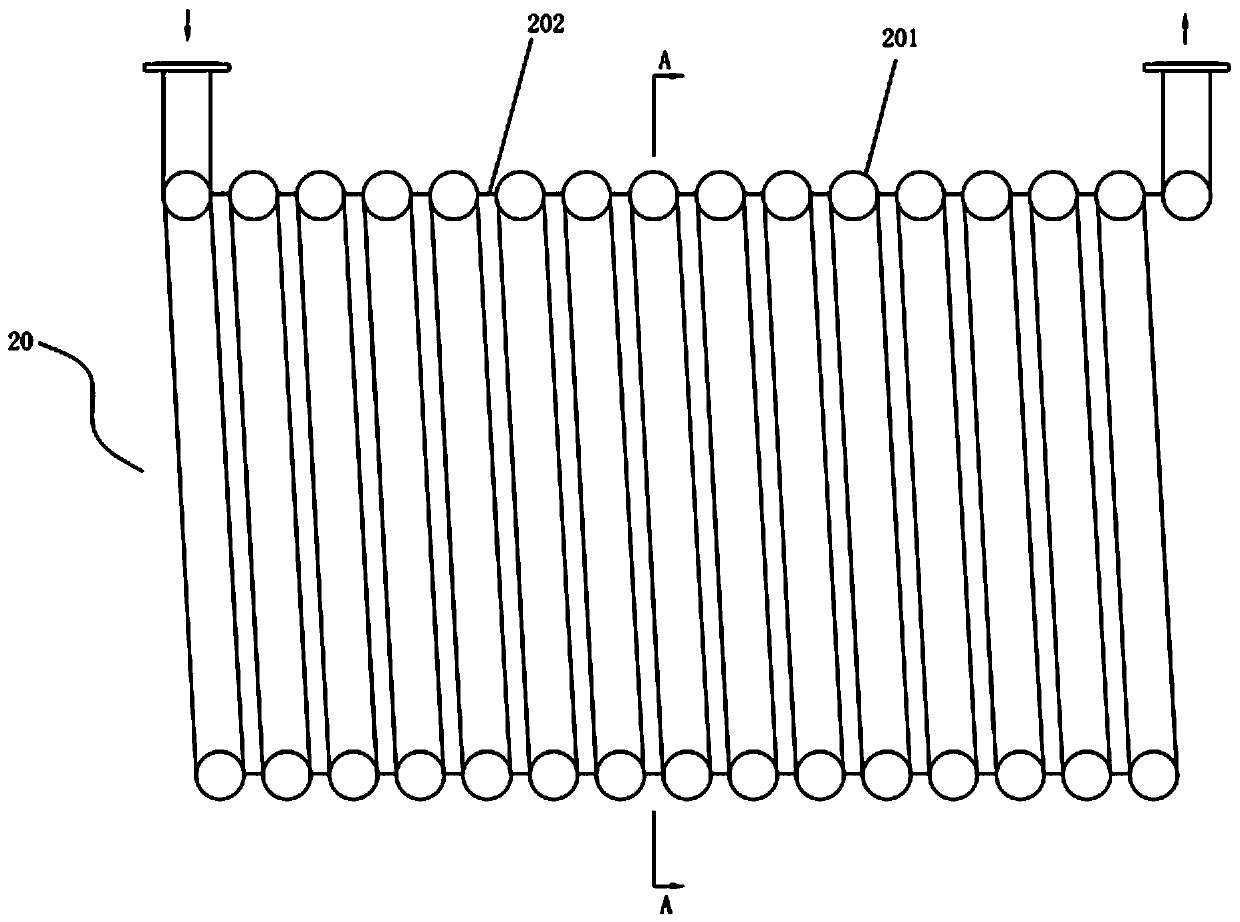

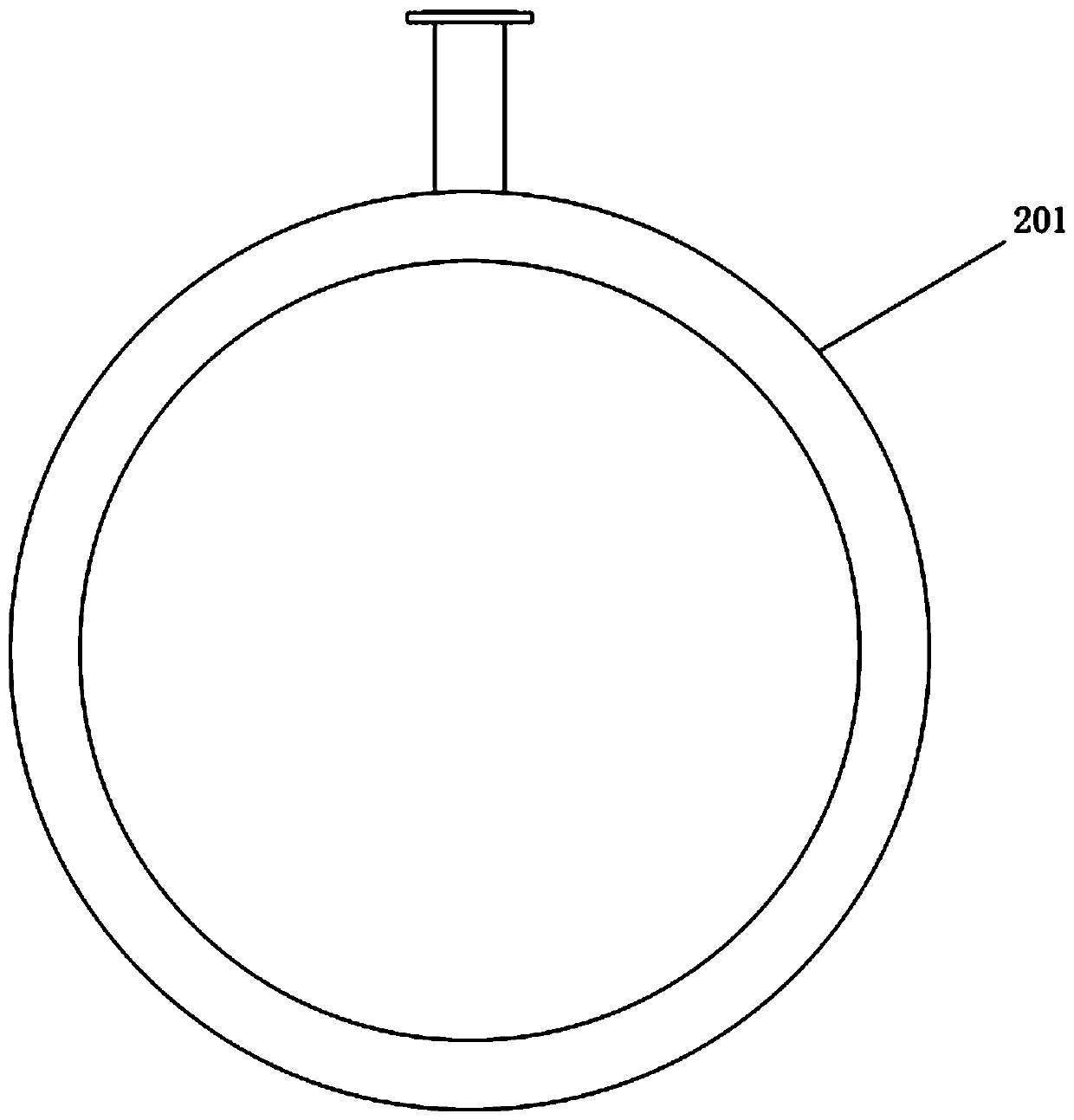

[0032] Such as figure 1 A kind of spiral coil membrane type fireplace hearth shown, it comprises: a spiral coil 201, a spiral sealing plate 202, the gap between each spiral of this spiral coil 201 is welded up with this spiral sealing plate 202, book To form a complete cylindrical membrane hearth 20 .

Embodiment 2

[0034] A spiral coil membrane fireplace body, which is provided with the spiral coil membrane fireplace chamber 20 in Embodiment 1, and end plates (not shown in the figure) are welded at both ends of the spiral coil membrane fireplace chamber 20, By means of this, a complete spiral coil membrane fireplace body 2 is formed.

[0035] The furnace body of embodiment 2 is convenient to use, and the simplest application is such as inputting heat into the furnace 20 of the spiral coil membrane fireplace body 2 through the end plate, such as inputting high-temperature flue gas, and cooling water from one end of the spiral coil tube 201 The cold water is input into the mouth, and the high-temperature flue gas scours the inner wall of the corrugated furnace horizontally, and the cold water is heated into hot water or steam, which is output from the hot water outlet (or steam outlet) at the other end of the spiral coil 201. In the above application, the heated water in the spiral coil 20...

Embodiment 3

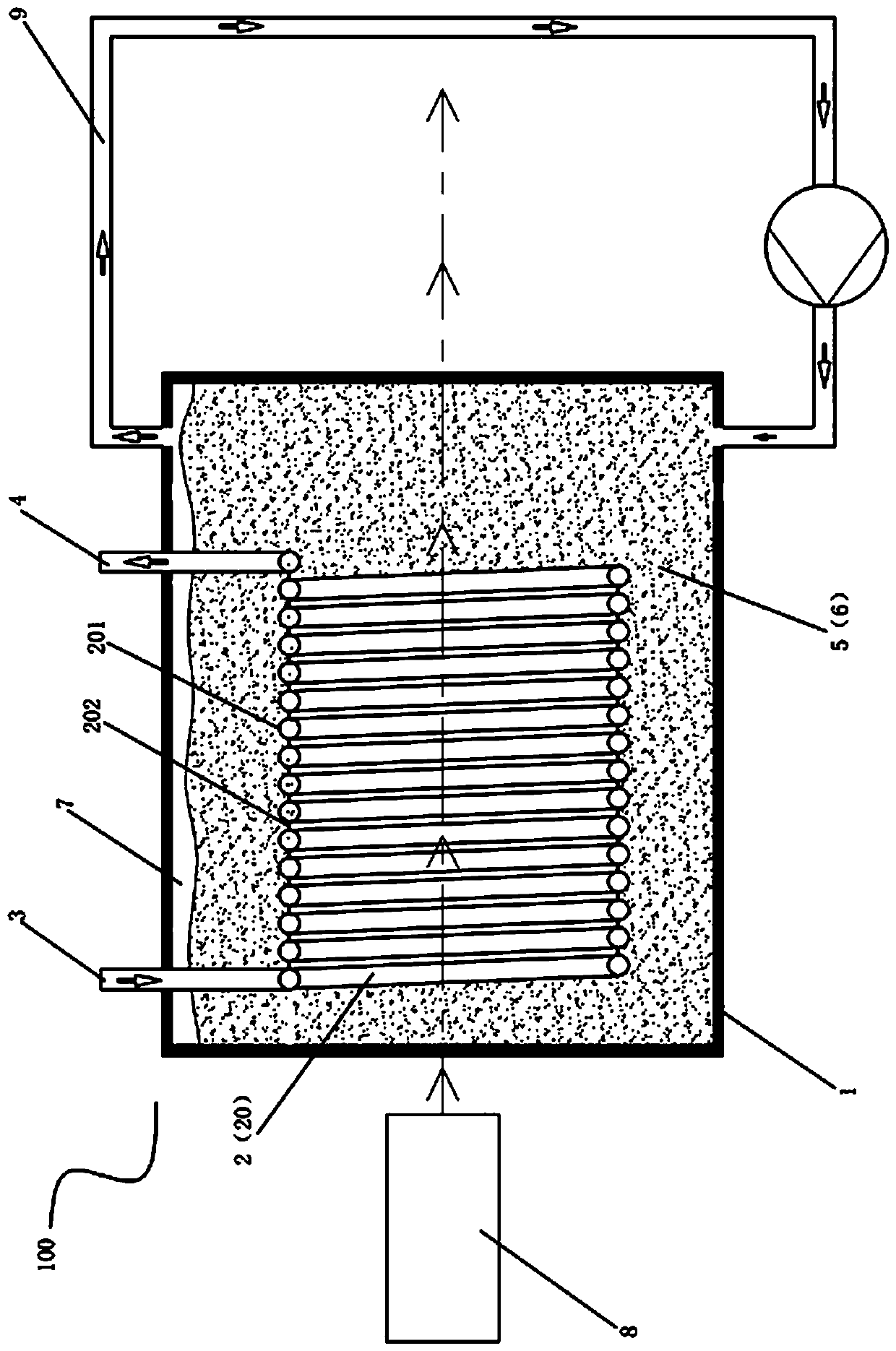

[0037] Such as image 3 A heat supply device 100 is shown, which includes: an oil tank cylinder 1, a spiral coil membrane fireplace body 2 in Embodiment 2, a water inlet pipe 3, a water vapor output pipe 4, and a gas-liquid circulation System 9, wherein the spiral coil membrane fireplace body 2 includes a furnace 20, the furnace 20 includes a spiral coil 201, a spiral sealing plate 202, and the gap between each spiral of the spiral coil 201 is welded with the spiral sealing plate 202 , the two ends of the furnace 20 are welded with end plates (not shown in the figure), the furnace body 2 is placed in the oil storage cylinder body 1, and a jacket space 5 is formed between the oil storage cylinder body 1 and the furnace body 2 , there is a high-boiling point liquid layer 6 in the jacket space 5, the high-boiling point liquid layer 6 is composed of a high-boiling point liquid energy-carrying medium with a boiling point of 340 ° C, and an air gap is formed between the high-boiling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com