Organic light emitting diode substrate and manufacturing method therefor

A technology of light-emitting diodes and substrates, which is applied in the fields of organic semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as uneven voltage distribution, viewing angle deviation, and low cathode transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

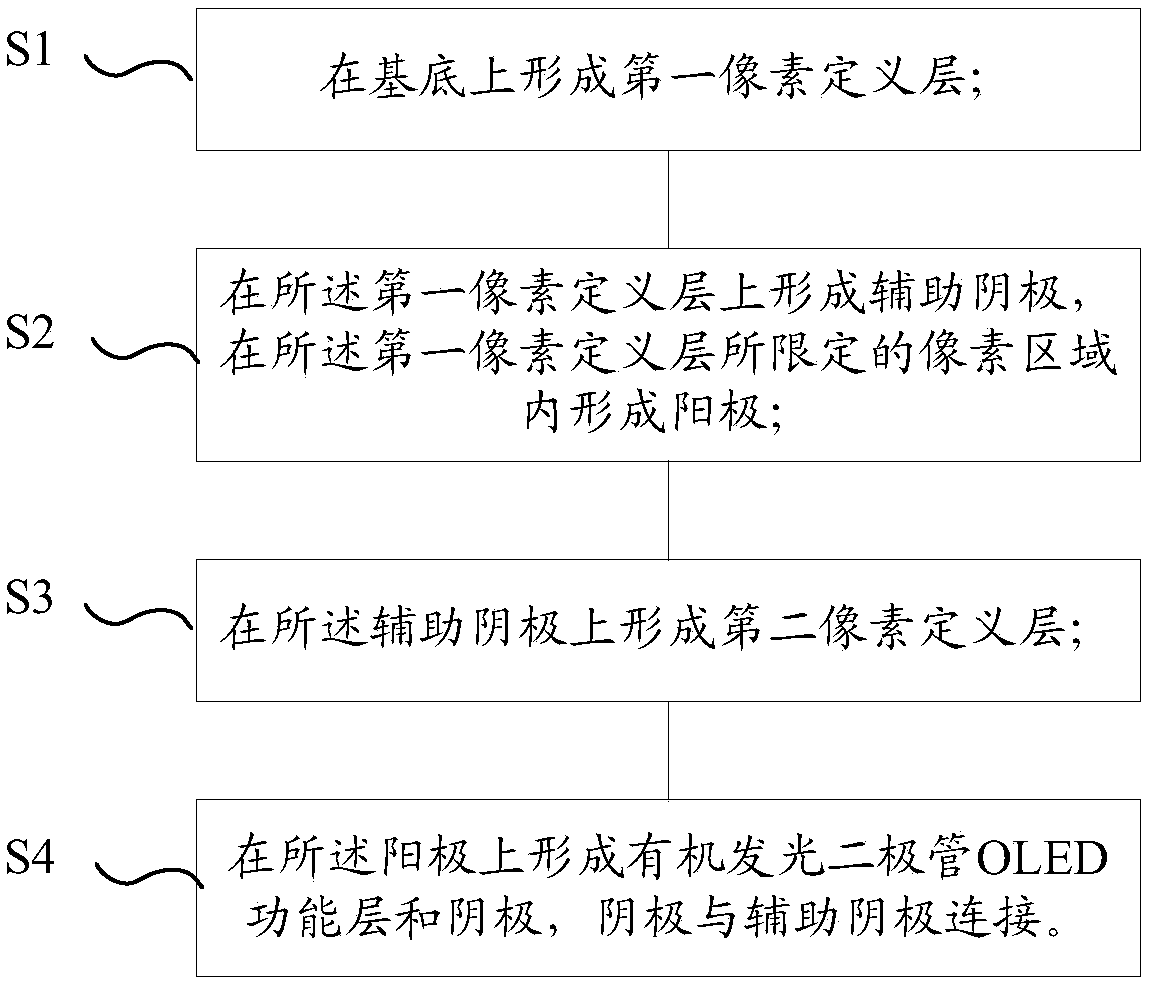

[0052] In order to simultaneously improve the light transmittance and conductivity of the top emission OLED, an embodiment of the present application provides a method for manufacturing an organic light emitting diode substrate. figure 1 It is a flowchart of a method for preparing an organic light emitting diode substrate according to an embodiment of the present invention. like figure 1 As shown, the preparation method of the organic light emitting diode substrate includes:

[0053] S1. Forming a first pixel definition layer on a substrate;

[0054] S2. Forming an auxiliary cathode on the first pixel definition layer, and forming an anode in a pixel region defined by the first pixel definition layer;

[0055] S3. Forming a second pixel definition layer on the auxiliary cathode;

[0056] S4, forming an OLED functional layer and a cathode on the anode, and the cathode is connected to the auxiliary cathode.

[0057] Wherein, step S1 includes: depositing a pixel-defining film...

no. 1 example

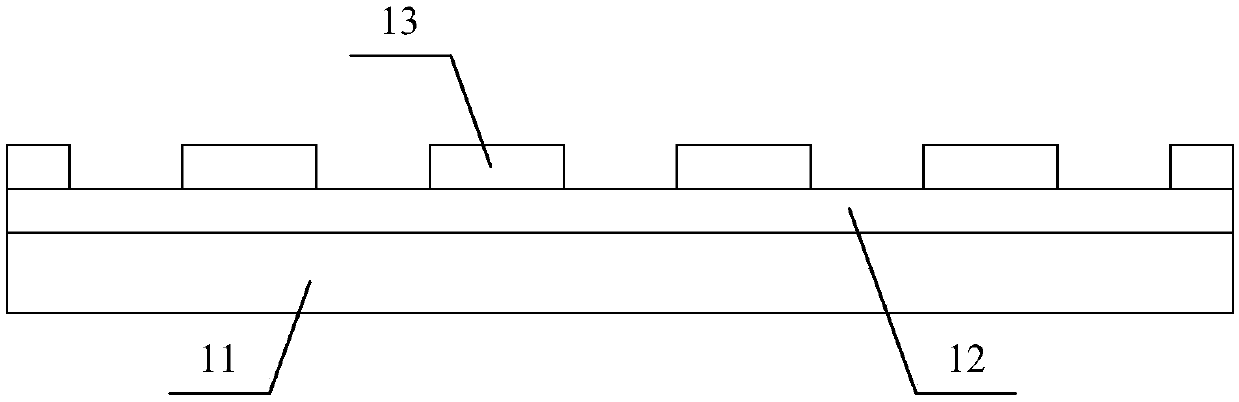

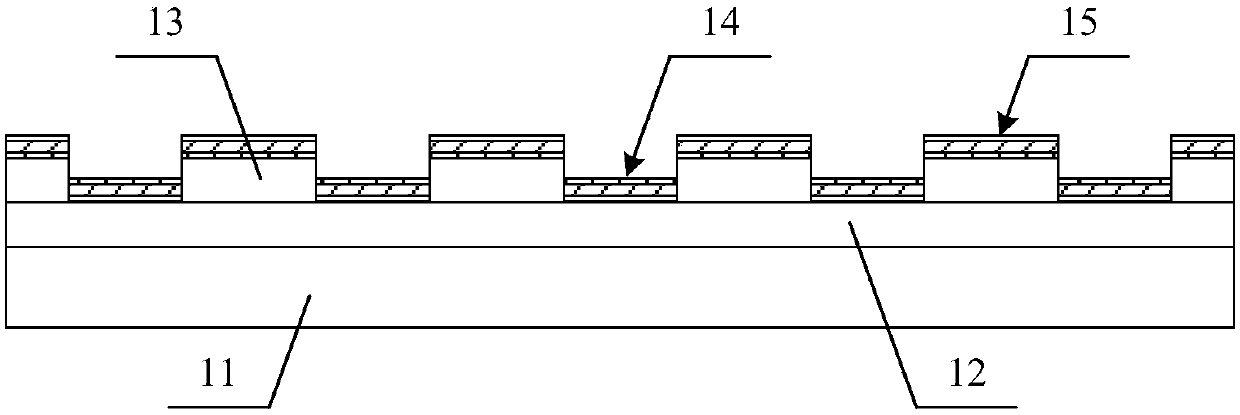

[0072] Figure 2-7 It is a schematic diagram of preparing an OLED substrate according to the first embodiment of the present invention. Combine below Figure 2-7 The method for preparing the organic light emitting diode substrate of this embodiment will be described in detail.

[0073] (1) Forming a pattern of the driving structure layer 12 on the substrate 11 through a patterning process. In this embodiment, the driving structure layer 12 includes a thin film transistor (Thin Film Transistor, TFT), and the structure and manufacturing process of the driving structure layer are the same as the existing manufacturing process. For example, the preparation process may include: cleaning the substrate first, and then sequentially preparing a gate electrode, an insulating layer, an active layer, a source-drain electrode and a flat layer on the substrate through a patterning process. The substrate material can be glass, quartz, polyethylene terephthalate (PET) or a surface-treated ...

no. 2 example

[0118] Figure 8 It is a schematic structural view of the OLED substrate according to the second embodiment of the present invention. The main structure of the OLED substrate of this embodiment is the same as that of the first embodiment, the difference is that the anode 14 and the auxiliary cathode 15 of this embodiment are only formed by a transparent conductive layer, and the thickness of the transparent conductive layer is 140-210 nm. Preferably, the thickness of the transparent conductive layer is 160-170 nm.

[0119] The process of preparing the organic light-emitting diode substrate in this embodiment is also similar to that of the first embodiment, the difference is that after the first pixel defining layer pattern is prepared, a transparent conductive layer is deposited by sputtering to form an anode 14 in the pixel area. pattern, the auxiliary cathode 15 pattern is formed on the first pixel defining layer, and the anode 14 and the auxiliary cathode 15 only include a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com