Anisotropic scattering film

An anisotropic, scattering film technology, applied in the field of anisotropic scattering films, can solve the problems of difficulty in maintaining a uniform dispersion state, poor uniformity, etc., and achieve good in-plane uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] (Example)

[0072] The polymerizable liquid crystal composition (A) of the composition shown below was prepared.

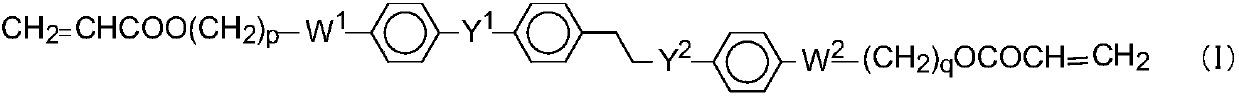

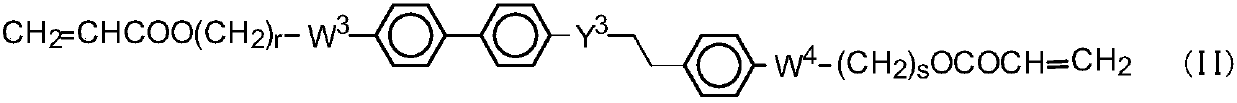

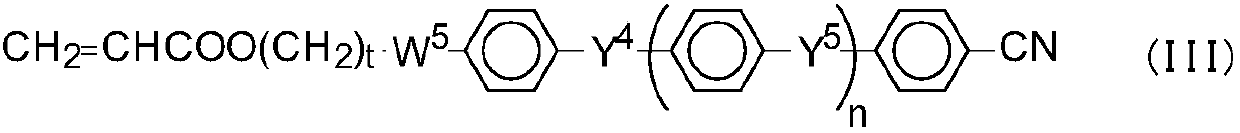

[0073] [chemical 9]

[0074]

[0075] The polymerizable liquid crystal composition (A) transforms into a nematic phase at 70° C. and a smectic A phase at 35° C. when it is heated once to an isotropic liquid phase and then cooled. This smectic A phase also remains at room temperature. Composition (A-1) was prepared by adding 3% of photopolymerization initiator IRGACURE 907 (manufactured by Ciba Specialty Chemicals) and 0.01% of polypropylene with a mass average molecular weight of 1650 as a horizontal alignment additive to this composition (A). . Furthermore, composition (A-1) was dissolved in propylene glycol monomethyl ether acetate so that the concentration might become 30%, and coating composition (A-2) was prepared.

[0076] Next, a TAC film (50 μm in thickness) having a width of 15 cm and a length of 15 cm was prepared, and rubbing treatment was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com