Cu-in-ga-se quaternary alloy sputtering target

A cu-in-ga-se, quaternary alloy technology, applied in the direction of sputtering plating, electrical components, metal material coating technology, etc., can solve the problems of unclear manufacturing methods and achieve excellent in-plane uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Weigh Cu, In, Ga and Se as raw materials so that the composition formula CuIn 1-x Ga x Se 2-y where x and y are 0.2 and 0, respectively. In addition, the concentration of each raw material at this time is 25%, 20%, 5%, and 50% for Cu, In, Ga, and Se, respectively.

[0054] These raw materials are put into a quartz ampoule, the inside is evacuated and sealed, and then placed in a furnace for synthesis. The temperature distribution is 5°C / min from room temperature to 100°C, 1°C / min to 400°C, 5°C / min to 550°C, and 5°C / min to 550°C. The rate of temperature increase up to 650°C was 1.66°C / min, and then it was kept at 650°C for 8 hours, and then cooled to room temperature in the inner furnace over 12 hours.

[0055] The CIGS synthesis raw material powder obtained in the above manner was subjected to hot pressing (HP) after passing through a 120-mesh sieve. The conditions for HP are that the temperature increase rate from room temperature to 750°C is 10°C / min, and then it...

Embodiment 2~ Embodiment 6

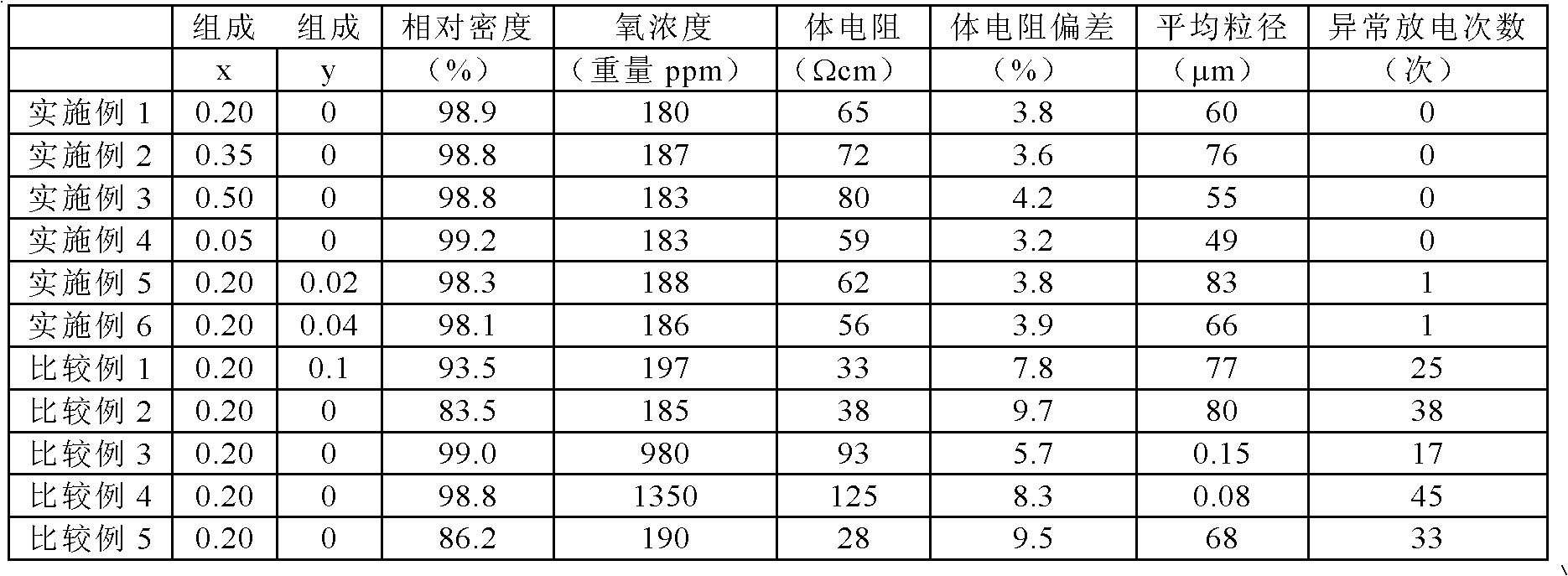

[0059] Table 1 summarizes the results of producing targets by changing the composition in the same manner as in Example 1, and performing sputtering evaluation. As shown in Table 1, in Examples 2 to 6, x representing the Ga concentration (atomic ratio) is in the range of 0<x≤0.5, and y representing the degree of selenium deficiency is in the range of 0≤y≤0.05.

[0060] As shown in Table 1, the relative density of the CIGS sintered body of Example 2 was 98.8%, the oxygen concentration was 187ppm, the volume resistance was 72Ωcm, the variation in volume resistance was 3.6%, and the average particle diameter was 76μm. In addition, regarding the number of abnormal discharges, the number of abnormal discharges in one hour between 20 hours and 21 hours after the sputtering time was counted, and it was 0 times.

Embodiment 3

[0061] The relative density of the CIGS sintered body of Example 3 was 98.8%, the oxygen concentration was 183 ppm, the volume resistance was 80 Ωcm, the variation in volume resistance was 4.2%, and the average particle diameter was 55 μm. In addition, regarding the number of abnormal discharges, the number of abnormal discharges in one hour between 20 hours and 21 hours after the sputtering time was counted, and it was 0 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com