Dry etching apparatus and dry etching method

A dry etching, etching gas technology, applied in coatings, electrical components, circuits, etc., can solve problems such as insufficient etching speed, and achieve the effect of high etching speed and good in-plane uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

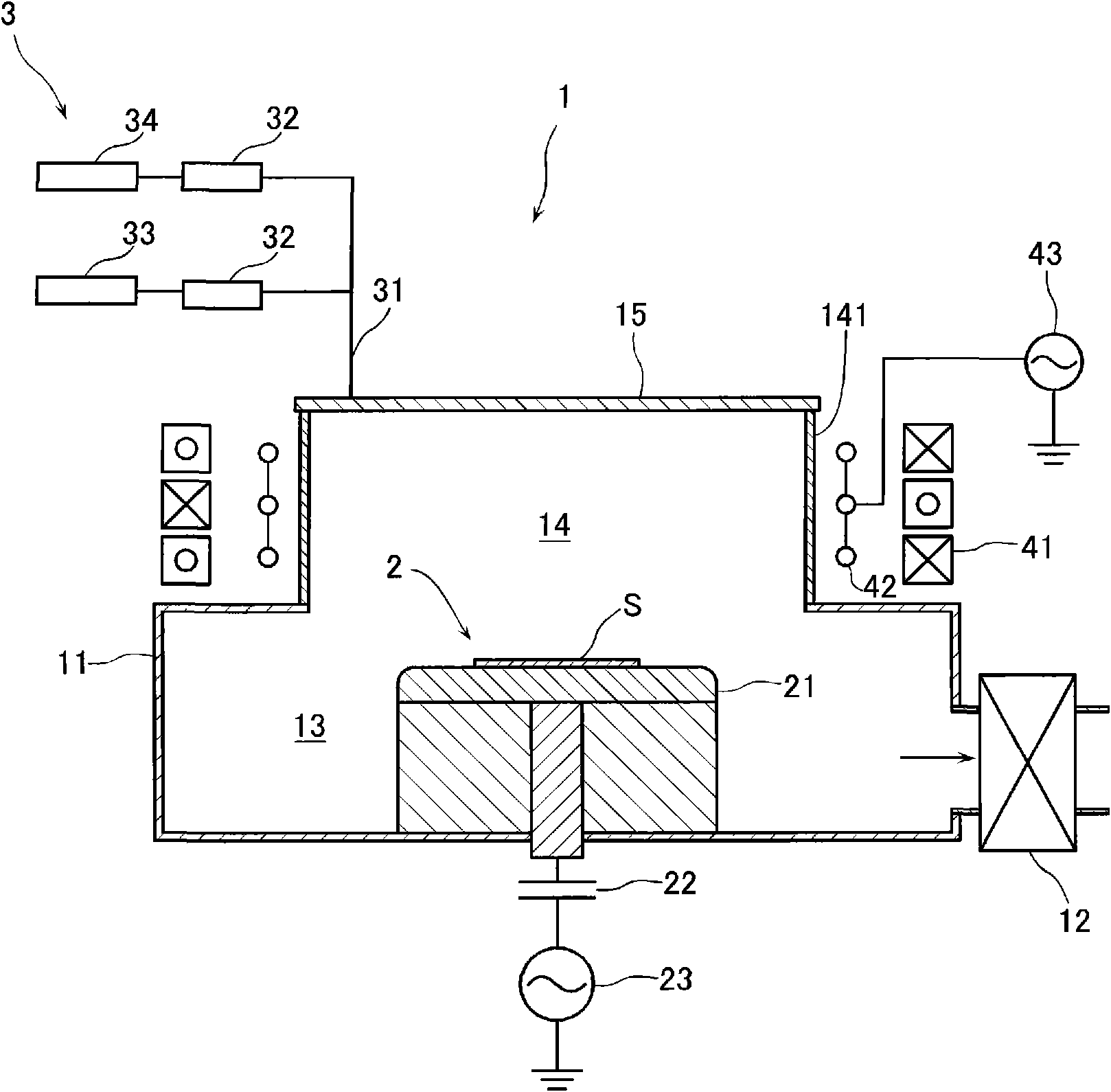

[0039] In this example, use figure 1 The etching device 1 shown performs etching. As the side wall 141, a product named SAPPHAL / Tokyo Ceramics Co., Ltd. was used as the translucent alumina ceramic (specific permittivity: 10, dielectric loss: 1×10 -4 ) to make.

[0040] First, on the substrate mounting table 2 of the etching device 1 in which the side wall 141 of the plasma generation chamber 14 is made of high-purity translucent alumina, a SiO substrate having a thickness of 1 μm is placed. 2 The substrate S to be processed, which is thin film and made of Si, generates plasma by the second high-frequency power supply 43, and at the same time introduces 3 f 8 The etching gas of gas 8 sccm and Ar gas 152 sccm etch the substrate S to be processed. The etching conditions were 400 W for the first high-frequency power supply (substrate side), 1200 W for the second high-frequency power supply (antenna side), set substrate temperature: -20° C., and pressure: 0.6 Pa.

[0041] Afte...

Embodiment 2

[0045] In this example, the difference from Example 1 is that a G-line resist layer was formed with a thickness of 2 μm as the resist layer, and etching was performed under exactly the same conditions except that. The substrate S to be processed was taken out from the etching apparatus 1, and the in-plane uniformity was examined, and the result was plus or minus 9.58%. In addition, the etching rate was 79.5 nm / min.

Embodiment 3

[0050] In this example, the difference from Example 1 is that the Si substrate was used as a sapphire substrate, and etching was performed under exactly the same conditions except that. The substrate S to be processed was taken out from the etching apparatus 1, and the in-plane uniformity was examined, and the result was plus or minus 5%. In addition, the etching rate was 350 nm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com