Method using mulberry silk to prepare viscose silk fibroin hydrogel

A technology of silk fibroin and regenerated silk fibroin, applied in the field of preparation of viscous silk fibroin hydrogel, can solve the problems of hyaluronic acid lack of mechanical strength, short retention time, high price, etc., and achieve considerable social and economic benefits , Improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Put 50g of mulberry silk into 2.5L boiling water containing 15g of melted soap for degumming treatment for 30min, remove the fibrous silk and wring it out, fully wash the soap with deionized water, repeat the above operation twice, Dry in an oven at 60°C for 15 hours to obtain desericinized silk;

[0018] 2) Dissolve the desericin silk obtained in step 1) in 50ml of LiBr solution with a concentration of 9.3M, put it in an oven at 60°C for 5 hours, and put the resulting solution in a dialysis bag and dialyze it with deionized water for 3 days , change the deionized water every 12h, and then use 9.0wt% polyethylene glycol (PEG) solution for reverse dialysis for 12h, then centrifuge the solution at 8000rpm for 30min, remove undissolved residue, and put it in 4°C Store in a refrigerator to obtain a high-concentration regenerated silk fibroin solution with a mass fraction of 6.0 wt %;

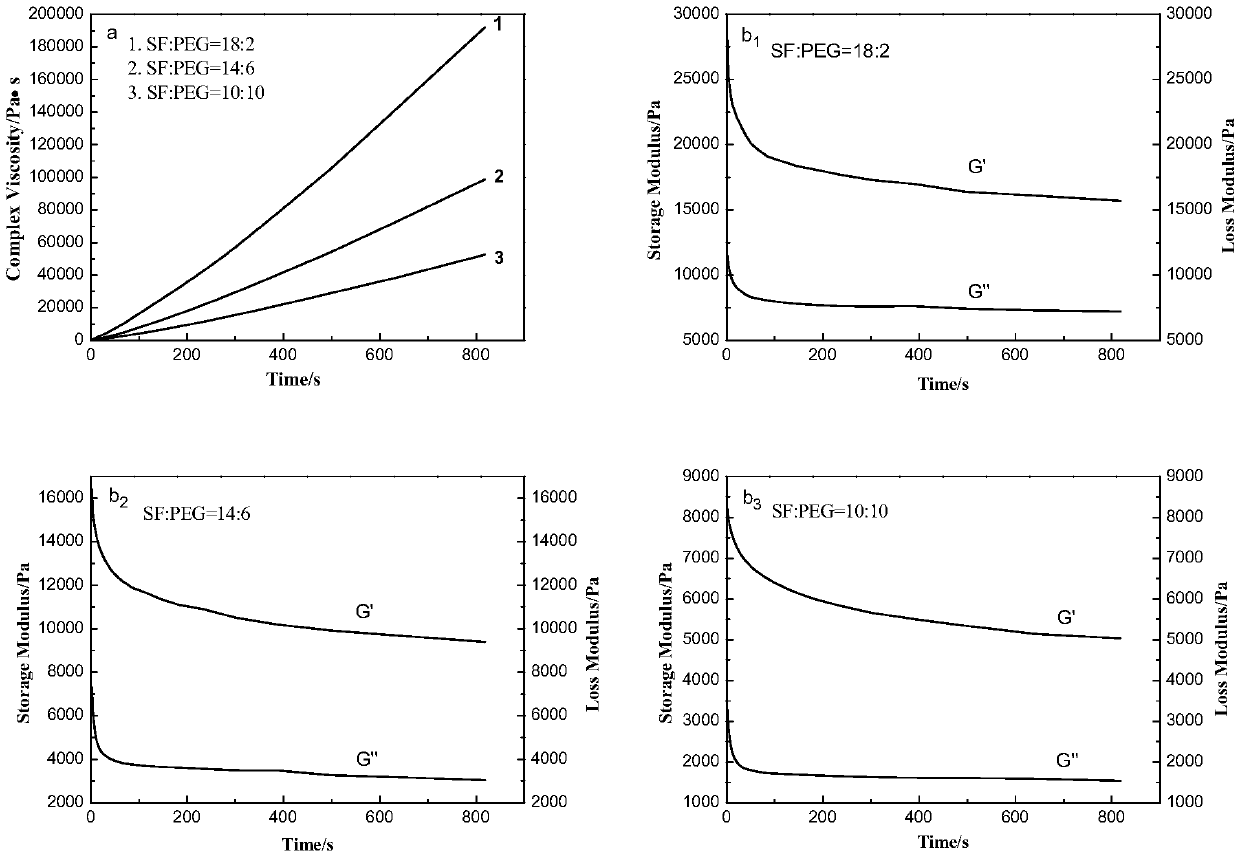

[0019] 3) Mix the high-concentration regenerated silk fibroin solution obtained in st...

Embodiment 2

[0021] 1) Put 50g of mulberry silk into 2.5L boiling water containing 15g of melted soap for degumming treatment for 35min, remove the fibrous silk and wring it out, fully wash the soap with deionized water, repeat the above operation 3 times, Dry in an oven at 55°C for 12 hours to obtain desericinized silk;

[0022] 2) Dissolve the desericin silk obtained in step 1) in 50ml of LiBr solution with a concentration of 9.3M, put it in an oven at 65°C for 4 hours, and put the resulting solution in a dialysis bag and dialyze it with deionized water for 3 days , change the deionized water every 12h, and then use 8.0wt% polyethylene glycol (PEG) solution for reverse dialysis for 18h, and then centrifuge the solution at 8000rpm for 40min to remove undissolved residue, and put it in 4°C Store in a refrigerator to obtain a high-concentration regenerated silk fibroin solution with a mass fraction of 7.0 wt %;

[0023] 3) Mix the high-concentration regenerated silk fibroin solution obtain...

Embodiment 3

[0025] 1) Put 50g of mulberry silk into 2.5L boiling water containing 15g of melted soap for degumming treatment for 40min, remove the fibrous silk and wring it out, fully wash the soap with deionized water, repeat the above operation twice, Dry in an oven at 65°C for 18 hours to obtain desericinized silk;

[0026] 2) Dissolve the desericin silk obtained in step 1) in 50ml of LiBr solution with a concentration of 9.3M, put it in an oven at 55°C for 3 hours, and put the resulting solution in a dialysis bag and dialyze it with deionized water for 3 days , change the deionized water every 12h, and then use 10.0wt% polyethylene glycol (PEG) solution for reverse dialysis for 15h, and then centrifuge the solution at 8000rpm for 35min to remove undissolved residue, and put it in 4°C Store in a refrigerator to obtain a high-concentration regenerated silk fibroin solution with a mass fraction of 8.0 wt %;

[0027] 3) Mix the high-concentration regenerated silk fibroin solution obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com