A high-level waste liquid vitrification system and its curing method

A high-level waste liquid and vitrification technology, which is applied in the field of spent fuel treatment, can solve the problems of large radioactive material diffusion risk, low efficiency, and high radiation risk of maintenance workers, and achieve the value of extensive engineering application and promotion, and the process design is reasonable , Improve the effect of maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings, and the embodiments of the present invention include but are not limited to the following examples.

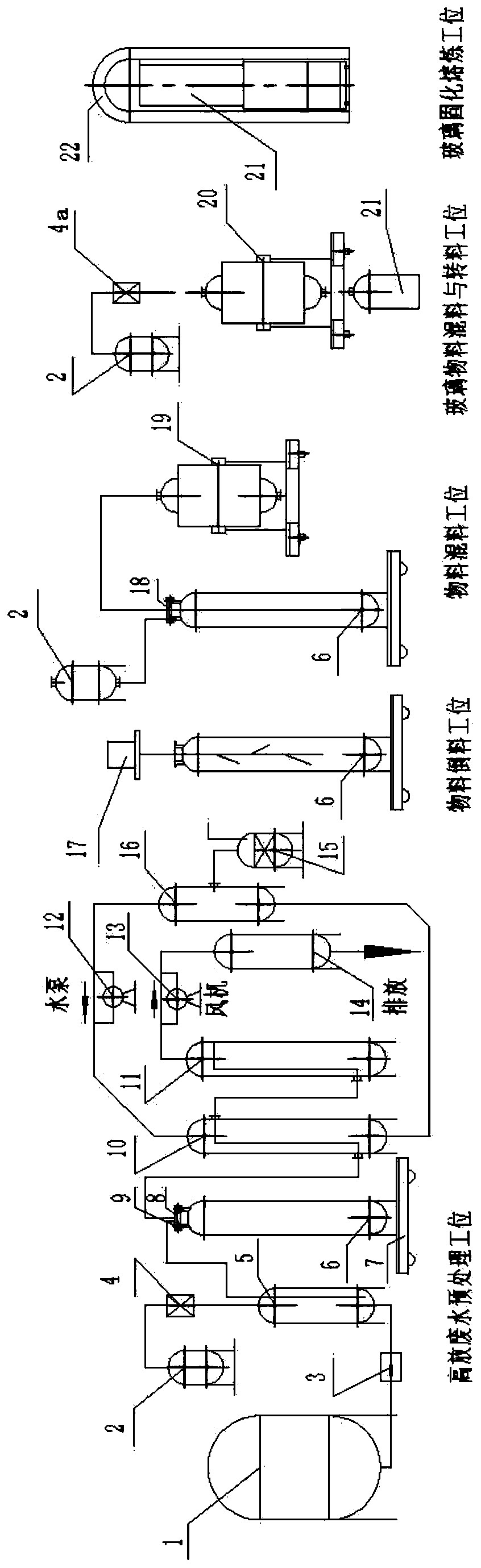

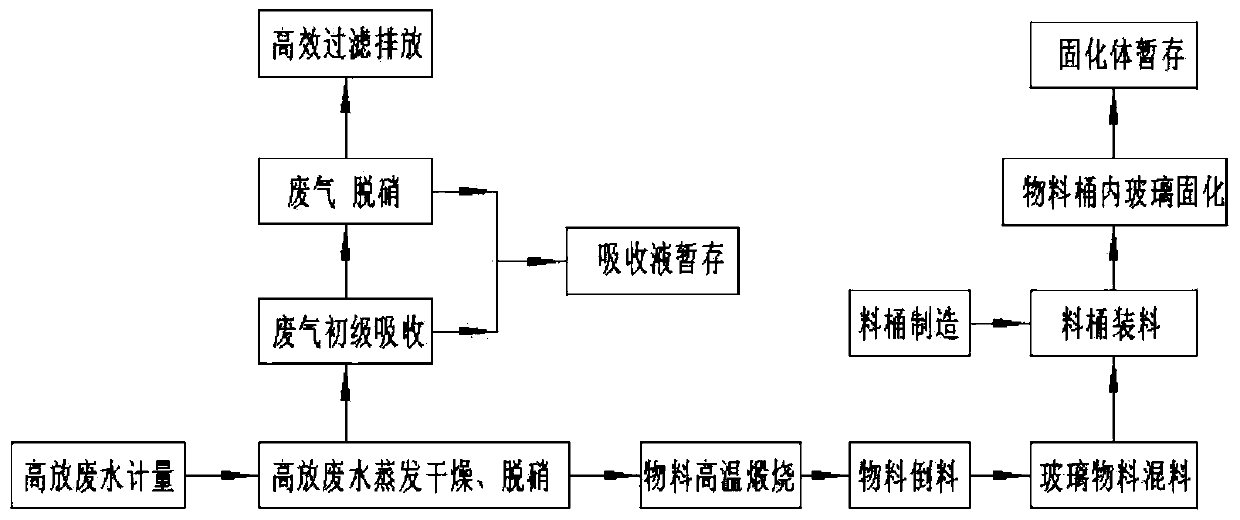

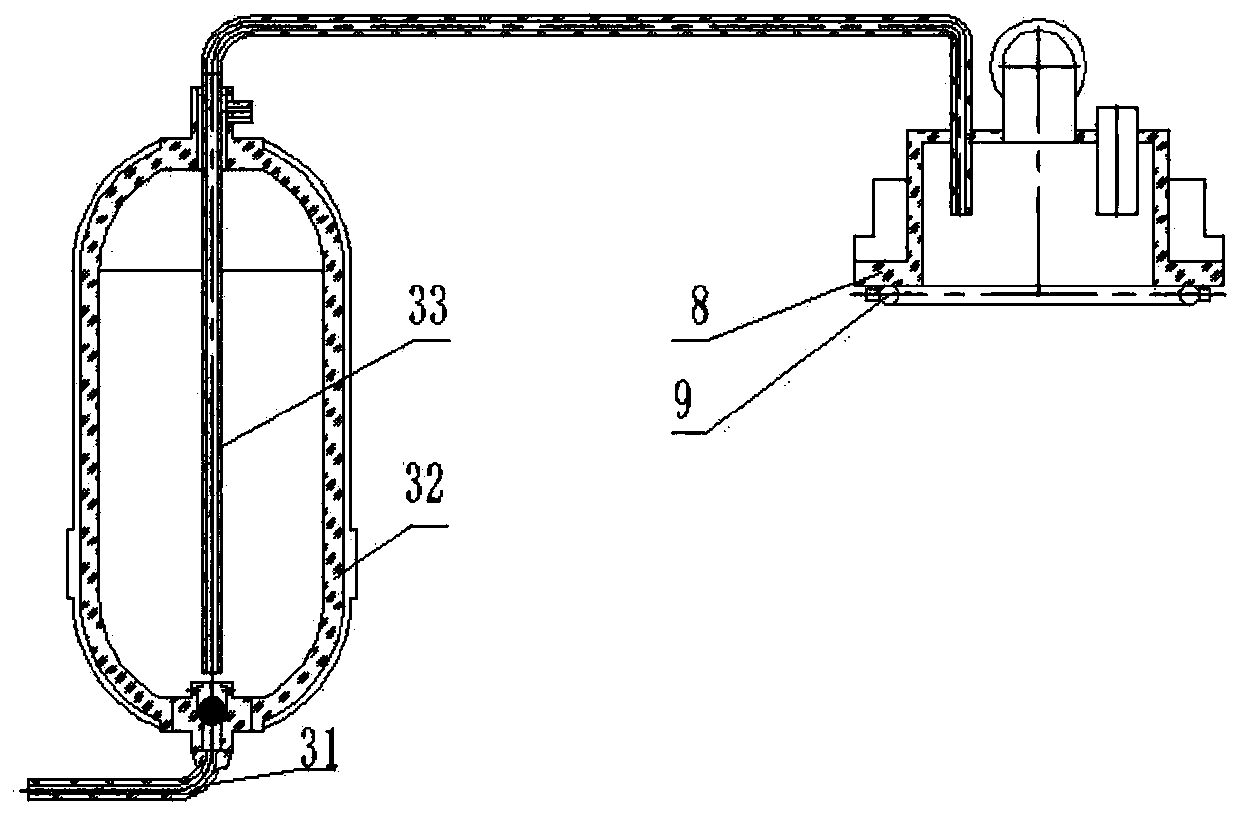

[0035] figure 1 Shown is a high-level waste liquid vitrification system of the present invention, including a high-level waste liquid temporary storage tank 1, a compressed air unit 2, a one-way valve 3, a pneumatic valve 4, a high-level waste liquid measuring tank 5, and a waste liquid Drying and calcination reaction kettle 6, reaction kettle driving mechanism 7, docking flange 8 (existing product), water-cooled sealing gasket 9, primary cooling tower 10, secondary cooling tower 11, circulating water pump 12, fan 13, denitrification Tower 14, water cooling unit 15, heat exchanger 16, slurry stirring device 17, another butt joint flange 18 (on the slurry pouring device), glass material mixer 19, glass material charging machine 20, glass material Bucket 21, vitrification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com