Bismuth/carbon nitride composite catalyst, and preparation method and applications thereof

A composite catalyst and bismuth-based technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of weak visible light response and low photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Bismuth / C 3 N 4 The preparation method of composite catalyst comprises the steps:

[0058] (1) Bi 2 o 3 / C 3 N 4 preparation of

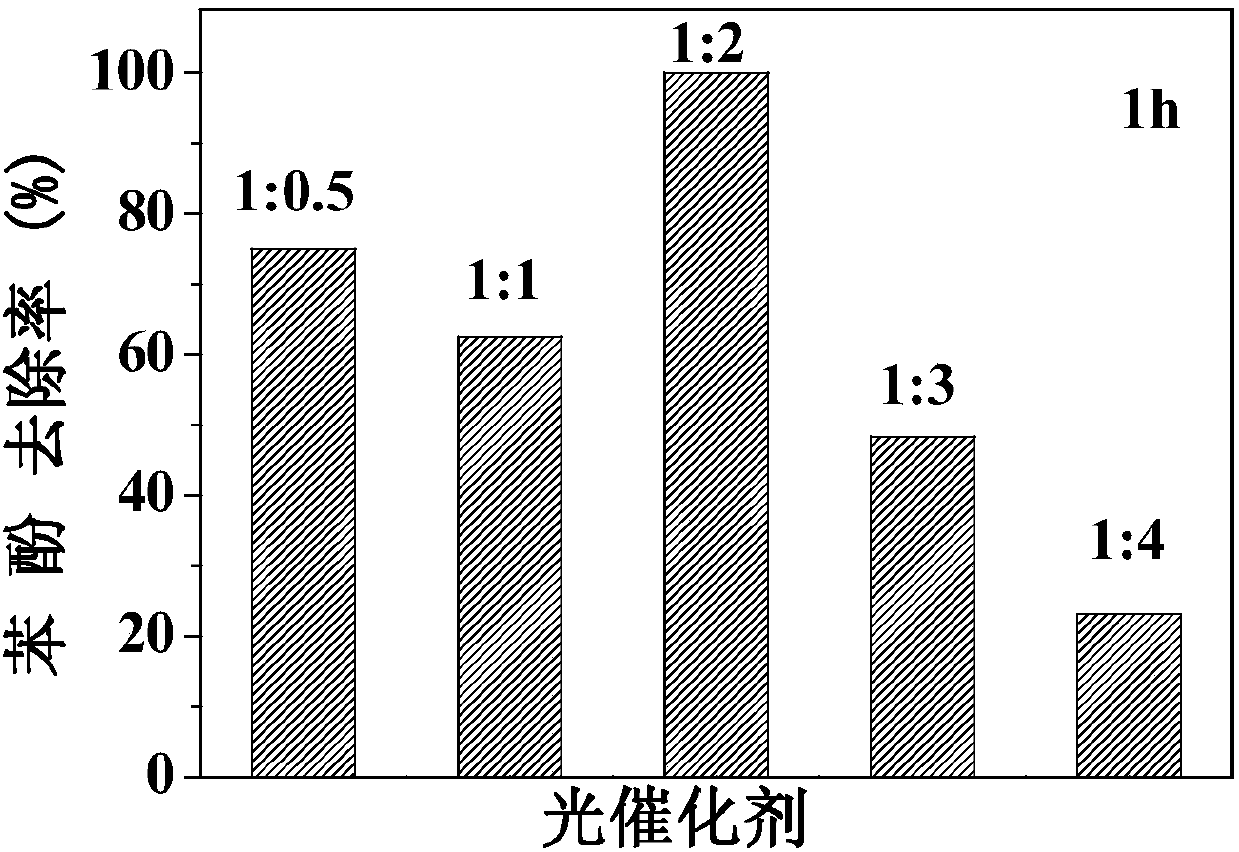

[0059] The catalyst uses melamine, dicyandiamide and urea as C 3 N 4 precursors. In order to exclude carbon nitride (C 3 N 4) effect on the performance of the catalyst (the molar ratio of fixed elements Bi and C, the initial ratio is set to 1:2, that is, Bi:C=1:2) set five ratios 1:1 to 1:5. The specific method is as follows (take 1:2 as an example):

[0060] 1) Mix 0.526g urea (urea) with 4.85g bismuth nitrate pentahydrate (Bi(NO 3 ).5H 2 (purity: 99.0%) placed in an agate mortar and mixed evenly, after grinding finely, using a dropper to drop 4-5 drops of deionized water and continue grinding, finally showing a thick white paste.

[0061] 2) Mix 0.368g melamine with 4.85g bismuth nitrate pentahydrate (Bi(NO 3 ).5H 2 (purity 99.0%) was placed in an agate mortar and mixed evenly, and then step 1 was repeated.

[0062] 3) Mix ...

Embodiment 1

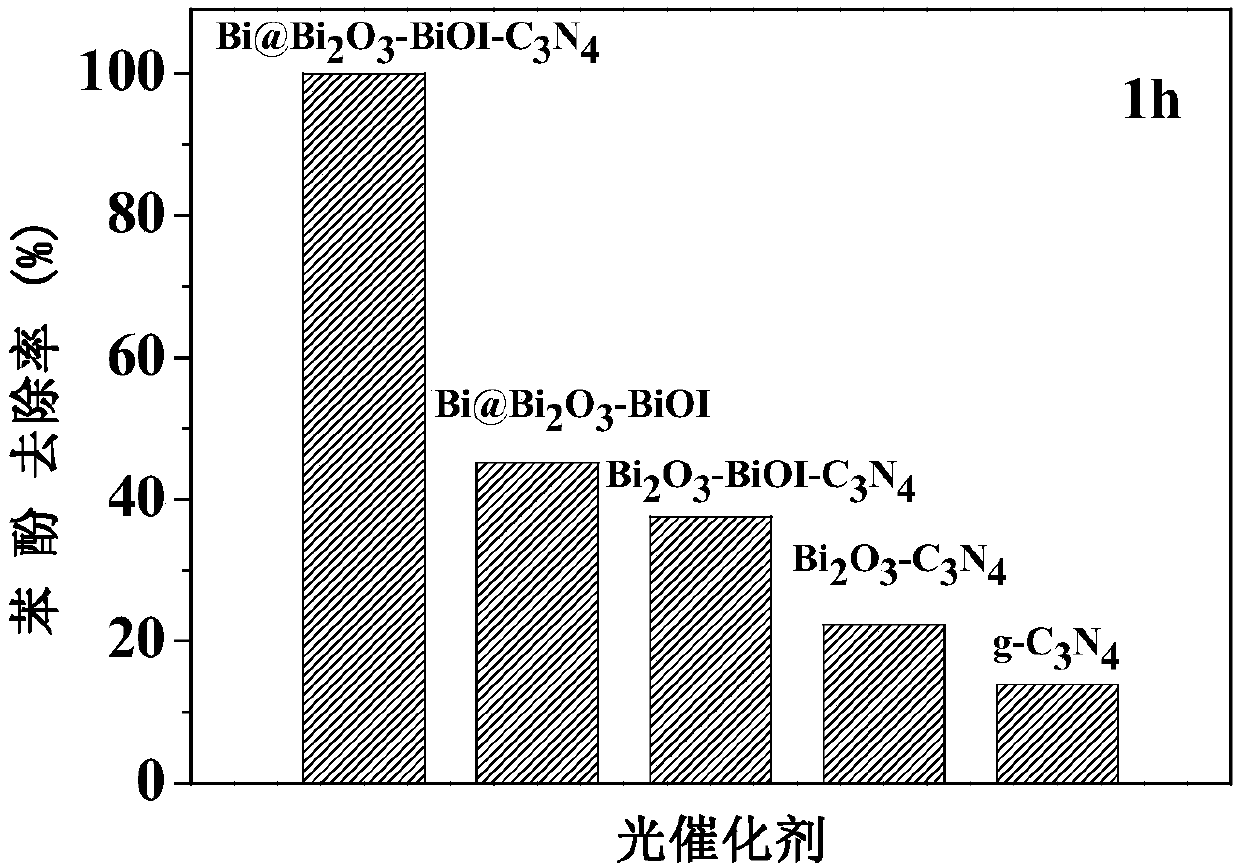

[0082] Catalysts containing 5 different components were selected, and the effectiveness of each component was determined by comparing their degradation performance. Depend on figure 1 , it can be found that when the light intensity is 100mW / m 2 , adding 50 mg of catalyst to 50 ml of 5 mg per liter of phenol solution, the trend of phenol degradation over time. Bi@Bi 2 o 3 -BiOI / C 3 N 4 It has the best degradation effect, and phenol is completely degraded in 60 minutes.

[0083] refer to figure 1 , found that although the degradation effect of the other four catalysts is not very good, and some are relatively poor, but through comparison, it can be found that:

[0084] 1) Compare g / C 3 N 4 and Bi 2 o 3 / C 3 N 4 In terms of degradation efficiency, it can be found that Bi 2 o 3 Doping can improve the catalytic degradation effect of the catalyst to a certain extent.

[0085] 2) Compare Bi 2 o 3 -BiOI / C 3 N 4 and Bi 2 o 3 / C 3 N 4 From the degradation efficie...

Embodiment 2

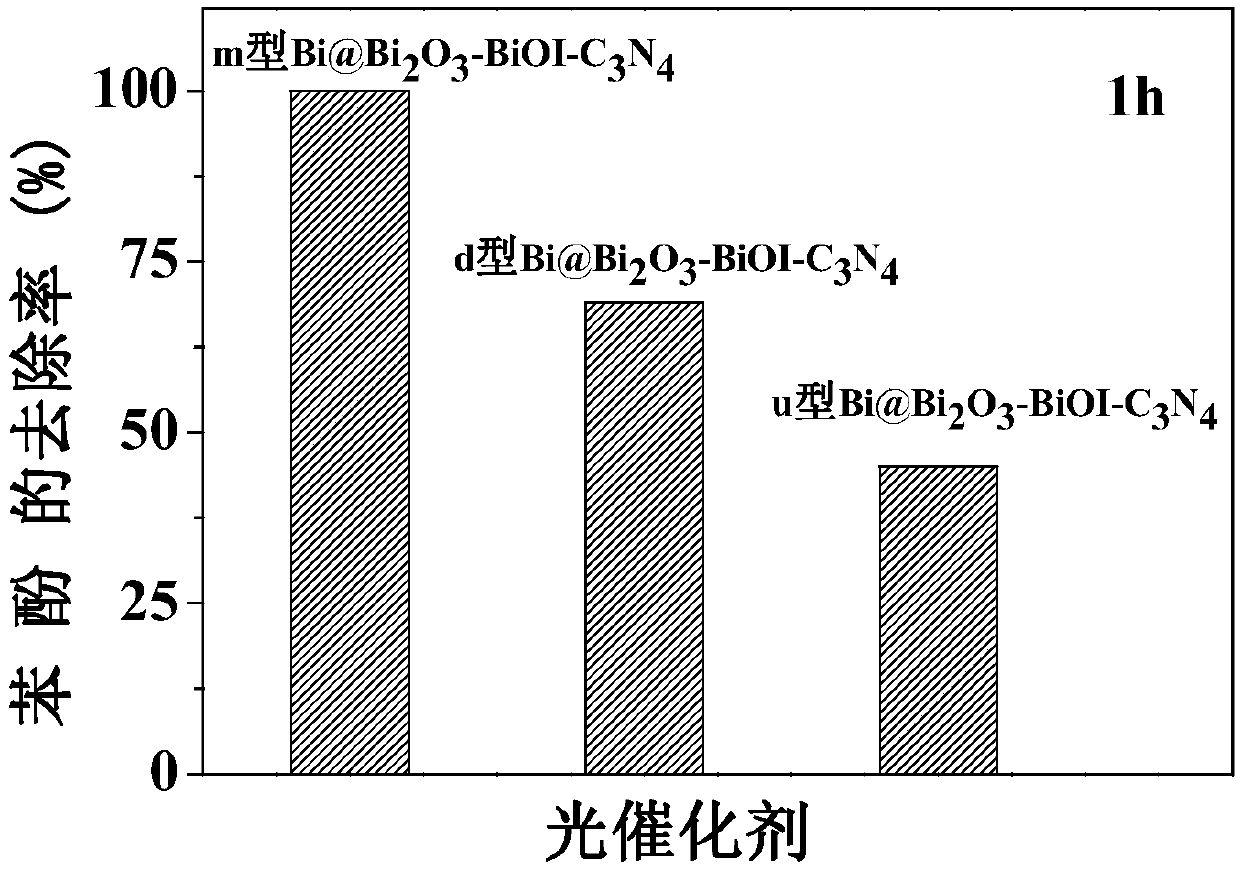

[0088] The effect of catalysts prepared from different carbon nitride precursors on the degradation performance of phenol was investigated. The experiment selects three common carbon nitride precursors, which are melamine, dicyandiamide and urea; respectively recorded as u-type Bi@Bi 2 o 3 -BiOI / C 3 N 4 (urea), m-type Bi@Bi 2 o 3 -BiOI / C 3 N 4 (melamine), d-type Bi@Bi 2 o 3 -BiOI / C 3 N 4 (dicyandiamide).

[0089] From the degradation effect diagram ( figure 2 ) It can be found that Bi@Bi prepared from three different precursors 2 o 3 -BiOI / C 3 N 4 It has a good degradation effect on phenol, but the m-type Bi@Bi 2 o 3 -BiOI / C3 N 4 (Using melamine as the precursor of carbon nitride) has the fastest degradation rate and can completely degrade phenol. The other two prepared catalysts also had good effects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com