Carbon nitride composite photocatalyst, preparation method and application thereof

A technology of composite light and catalyst, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low activity of visible light and weak adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] BiVO 4 / Ag 3 VO 4 Loaded ultrasonic peeling C 3 N 4 The preparation method of composite photocatalyst comprises the steps:

[0059] (1) Preparation of ultrasonically peeled C 3 N 4 weak:

[0060] 1) Put 5 g of melamine in an agate mortar, grind it vigorously, transfer it to a 50 mL crucible, and place it in a muffle furnace for calcination at 500° C. for 2 hours.

[0061] 2) After taking out the crucible, C was obtained after centrifugation, drying and grinding. 3 N 4 powder.

[0062] 3) Take 0.1gC 3 N 4 The powder is placed in 100mL of 50% ethanol solution, after continuous ultrasonication for six hours, centrifuged at 10000ram / min for 5min, the uniform milky white solution remains, which is the C 3 N 4 weak.

[0063] (2) Preparation of BiVO 4 / Ag 3 VO 4 Loaded ultrasonic peeling C 3 N 4 Composite photocatalyst:

[0064] 1) Add 0.485g Bi(NO 3 ) 3 .5H 2 O powder with 0.170g AgNO 3 Powder placed in 40mL C 3 N 4 The ultrasonic stripping solution ...

Embodiment 1

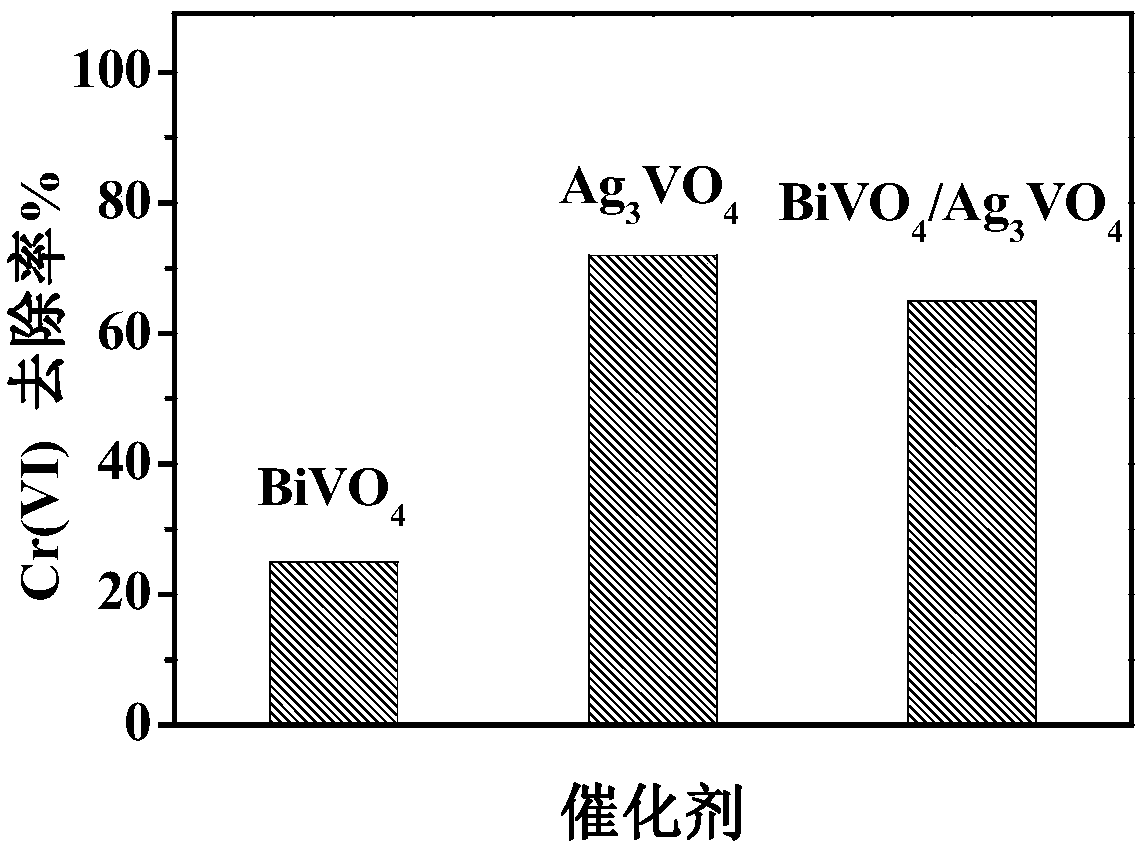

[0069] Catalysts containing three different components were selected, and the effectiveness of each component was determined by comparing their degradation performance. The catalyst preparation process is as follows:

[0070] (1) BiVO 4 Preparation: Bi(NO 3 ) 3 .5H 2 O powder was ground in a mortar, placed in water, and then sodium vanadate solution was added dropwise. After stirring for 2 hours, BiVO was obtained after centrifugation, drying and grinding. 4 powder.

[0071] (2)Ag 3 VO 4 Preparation: AgNO 3 After the powder is ground in a mortar, it is placed in water, and then sodium vanadate solution is added dropwise. After stirring for 2 hours, Ag is obtained after centrifugation, drying and grinding. 3 VO 4 powder.

[0072] (3) BiVO 4 / Ag 3 VO 4 Preparation: Bi(NO 3 ) 3 .5H 2 O powder and AgNO 3 The powder was stirred in aqueous solution for 1 hour. Add an excess of 0.1mol / L Na dropwise 3 VO 4 solution, after stirring for 2 hours, BiVO was obtained aft...

Embodiment 2

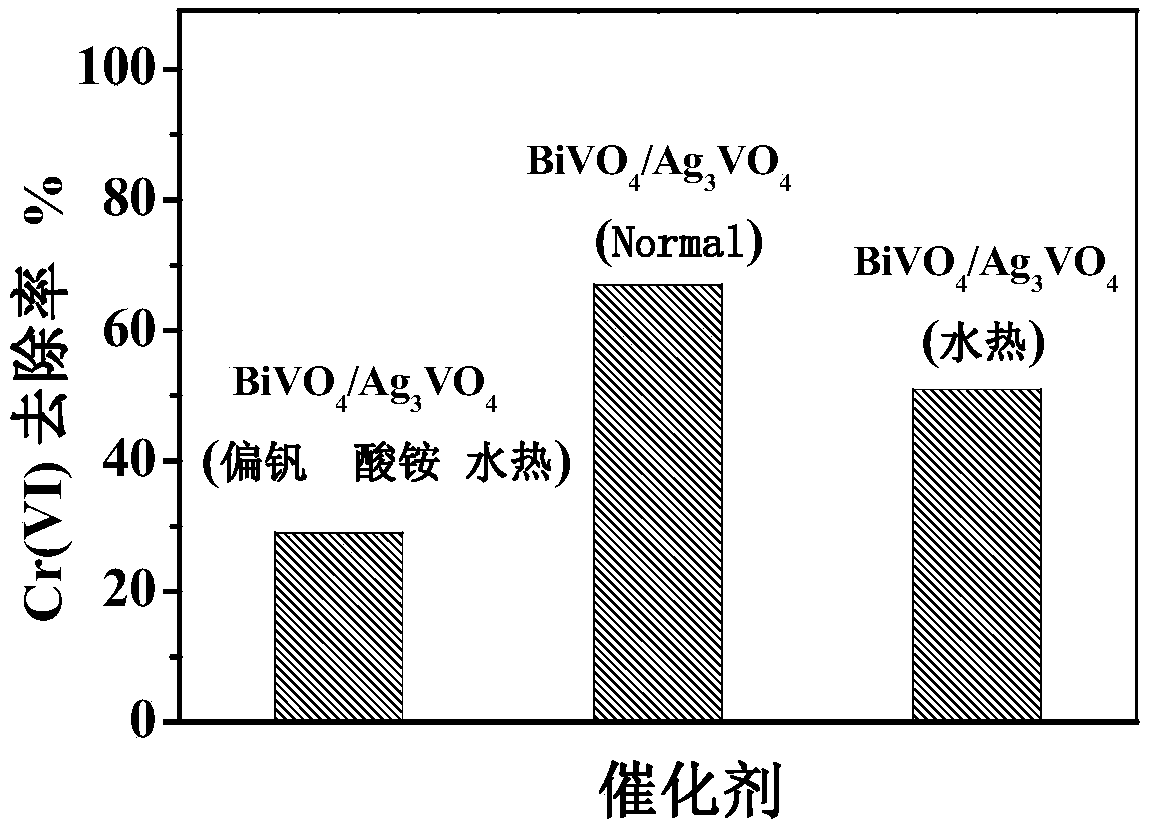

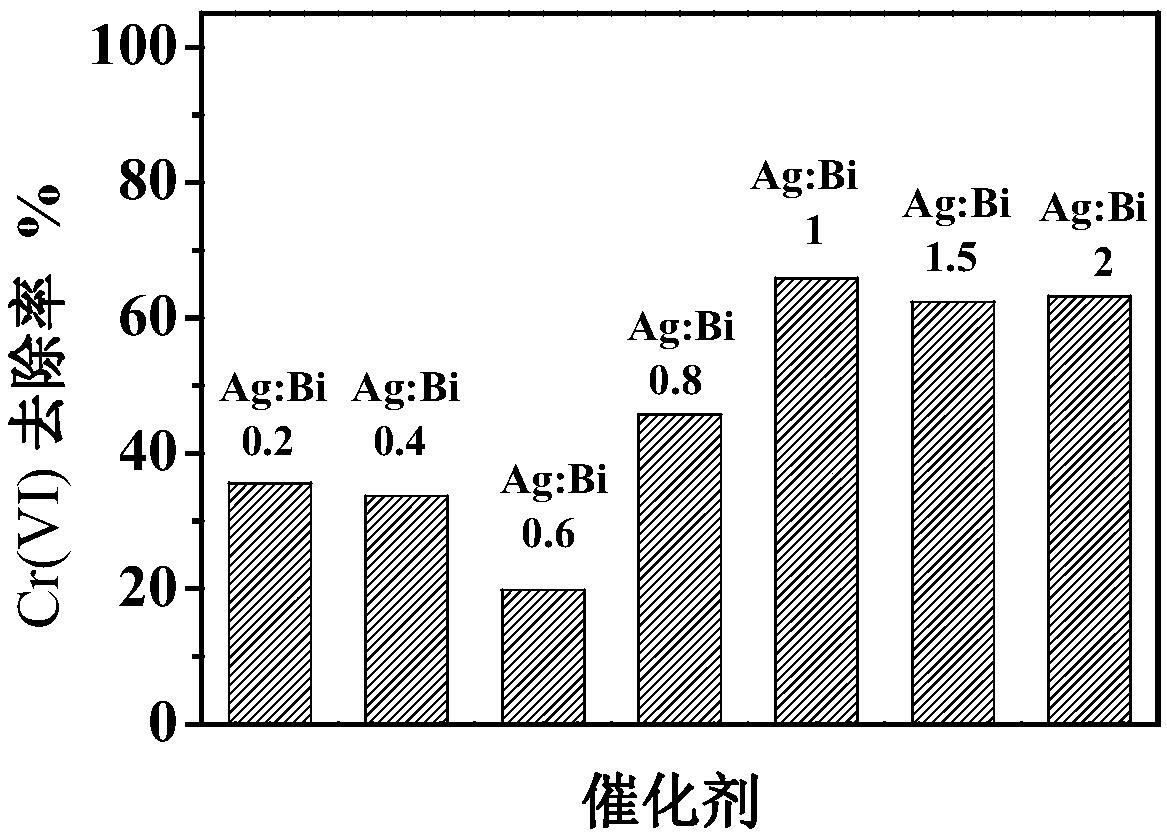

[0074] Explore BiVO 4 / Ag 3 VO 4 The influence of different preparation methods in the catalyst on the performance of the catalyst.

[0075] (1) Mix 0.485g bismuth nitrate + 0.17g silver nitrate, add excess sodium vanadate solution (15mL) dropwise, and stir for 2 hours.

[0076] (2) 0.485g bismuth nitrate + 0.17g silver nitrate were mixed, and excess sodium vanadate solution (15mL) was added dropwise, stirred for 20min, and placed in an autoclave at 140°C for 20 hours.

[0077] (3) Excessive ammonium metavanadate solution + bismuth nitrate were mixed and stirred for 20 minutes, placed in an autoclave at 140°C for 20 hours, and 0.324g BiVO was taken after drying 4 + 0.17g of silver nitrate were mixed, and excess sodium vanadate solution (5ml) was added dropwise, and stirred overnight.

[0078] The three catalysts were centrifugally washed, dried and ground to obtain BiVO prepared by different methods 4 / Ag 3 VO 4 .

[0079] Respectively recorded as BiVO 4 / Ag 3 VO 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com