BMC line spraying system and spraying process

A work station and spray booth technology, applied in liquid spraying equipment, coatings, spray booths, etc., can solve the problems of unreasonable space layout, low product qualification rate, large floor space, etc., and achieve high utilization rate of human space, High product qualification rate and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

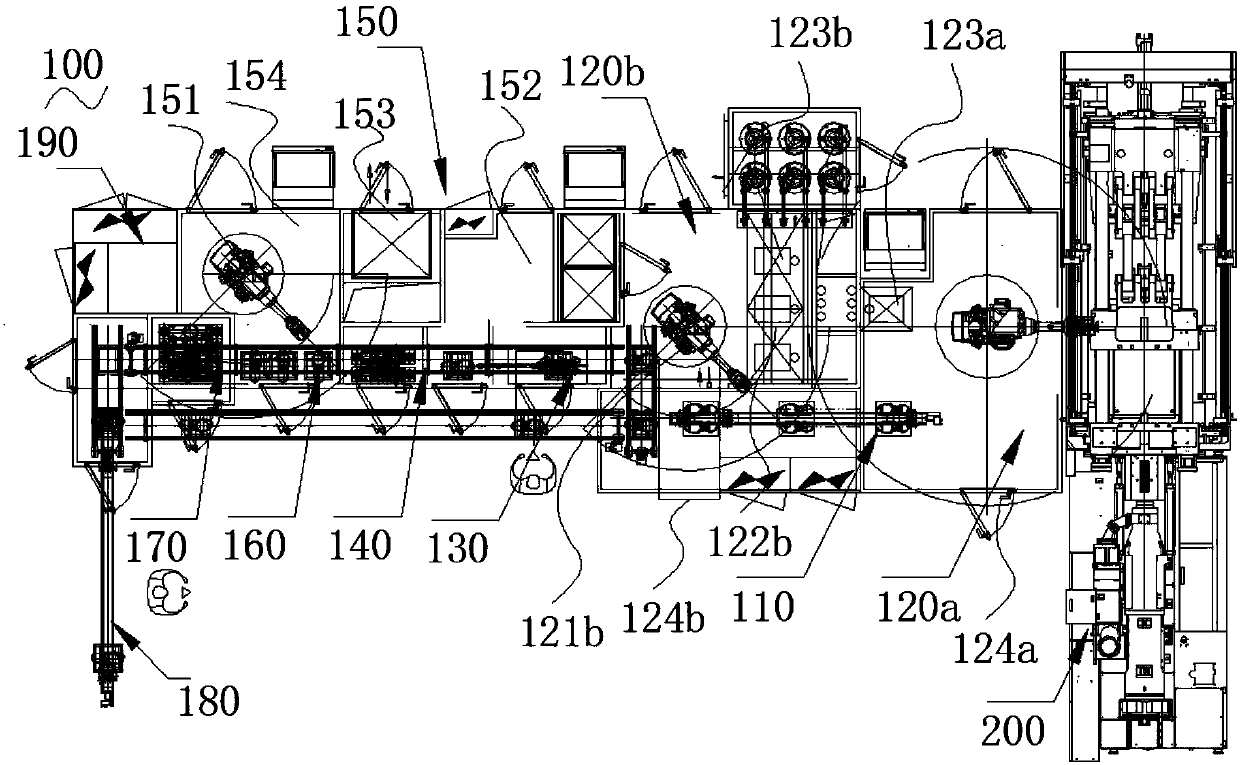

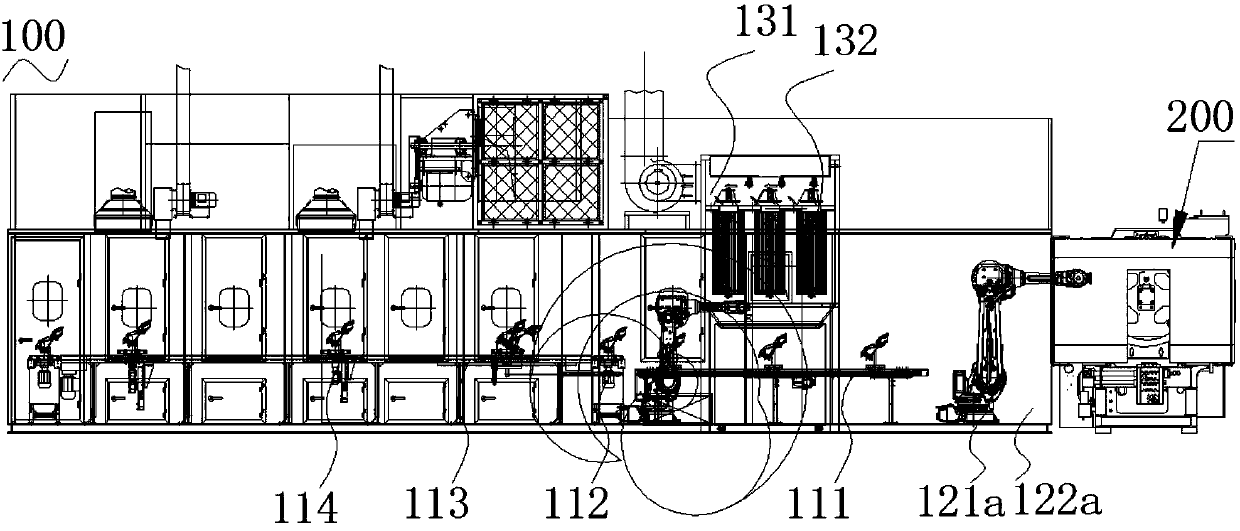

[0035] Such as figure 1 and figure 2 Shown, are the front view and top view of the present invention respectively.

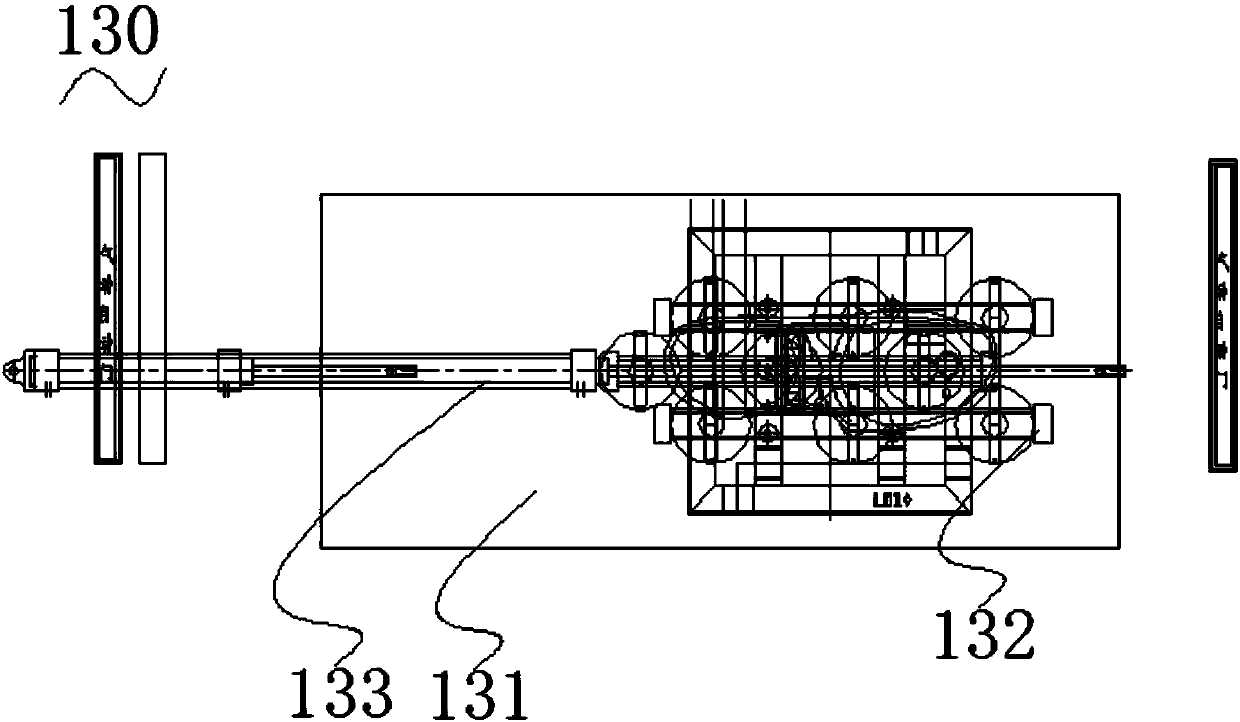

[0036] The BMC line spraying system 100 includes a feeding station 110 for feeding products after injection molding, a preliminary repair station 120a for preliminary trimming of products, and a finisher for secondary trimming of products Position 120b, the dedusting station 130 for dedusting the trimmed product, the UV pretreatment station 140 for UV pretreatment of the dedusted product, and the UV pretreatment station 140 for spraying the UV pretreated product Paint spraying station 150, buffer leveling station 160 for buffering and leveling the products after painting, UV curing station 170 for UV curing of products after buffering and leveling, for products after UV curing The blanking station 180 for cooling and blanki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com