Charging and discharging robot for toothbrush production assembly line

A production line, loading and unloading technology, applied in the field of loading and unloading manipulators, can solve the problems of unsuitability for popularization, high operation and maintenance costs, high production equipment purchase costs, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

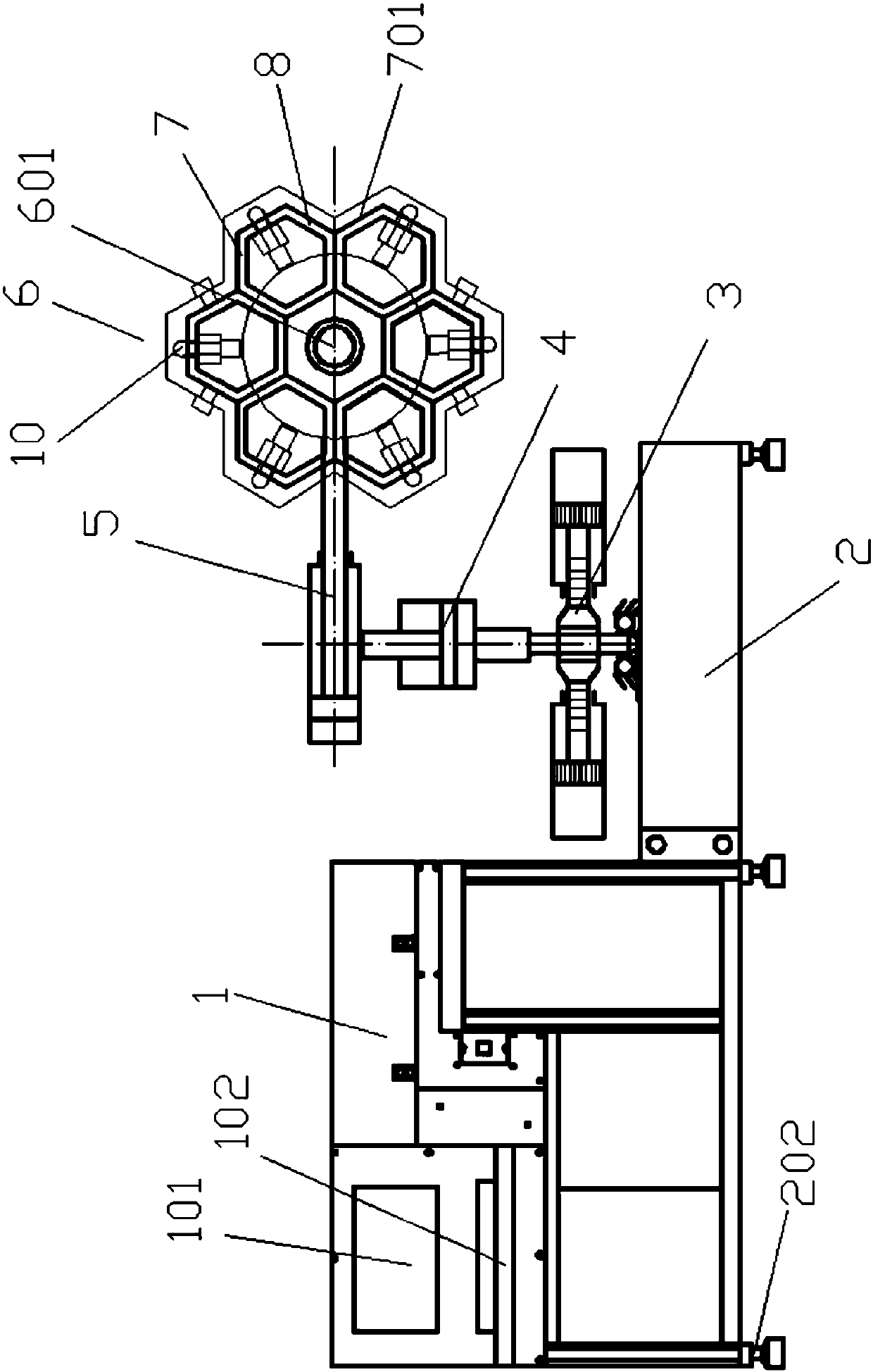

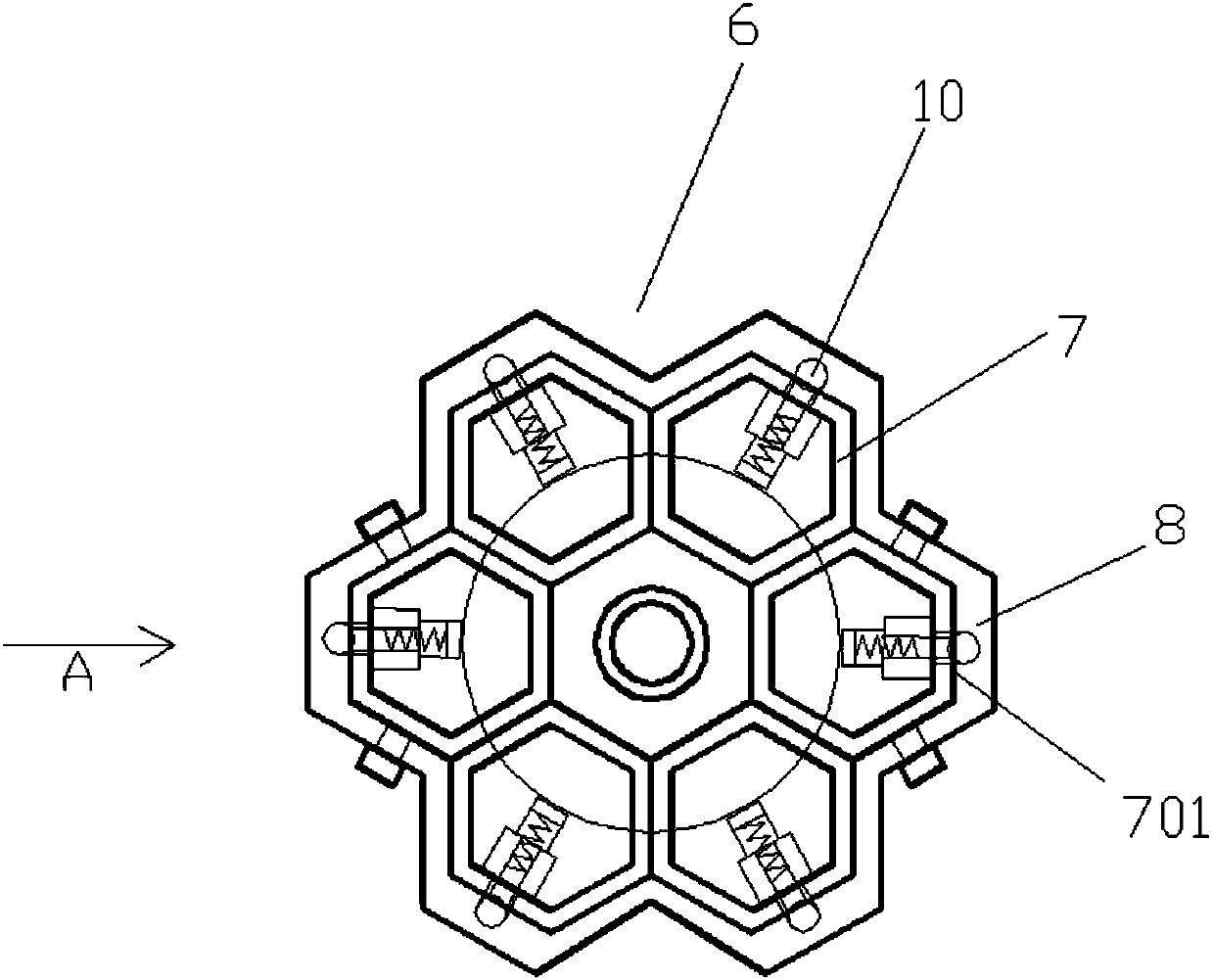

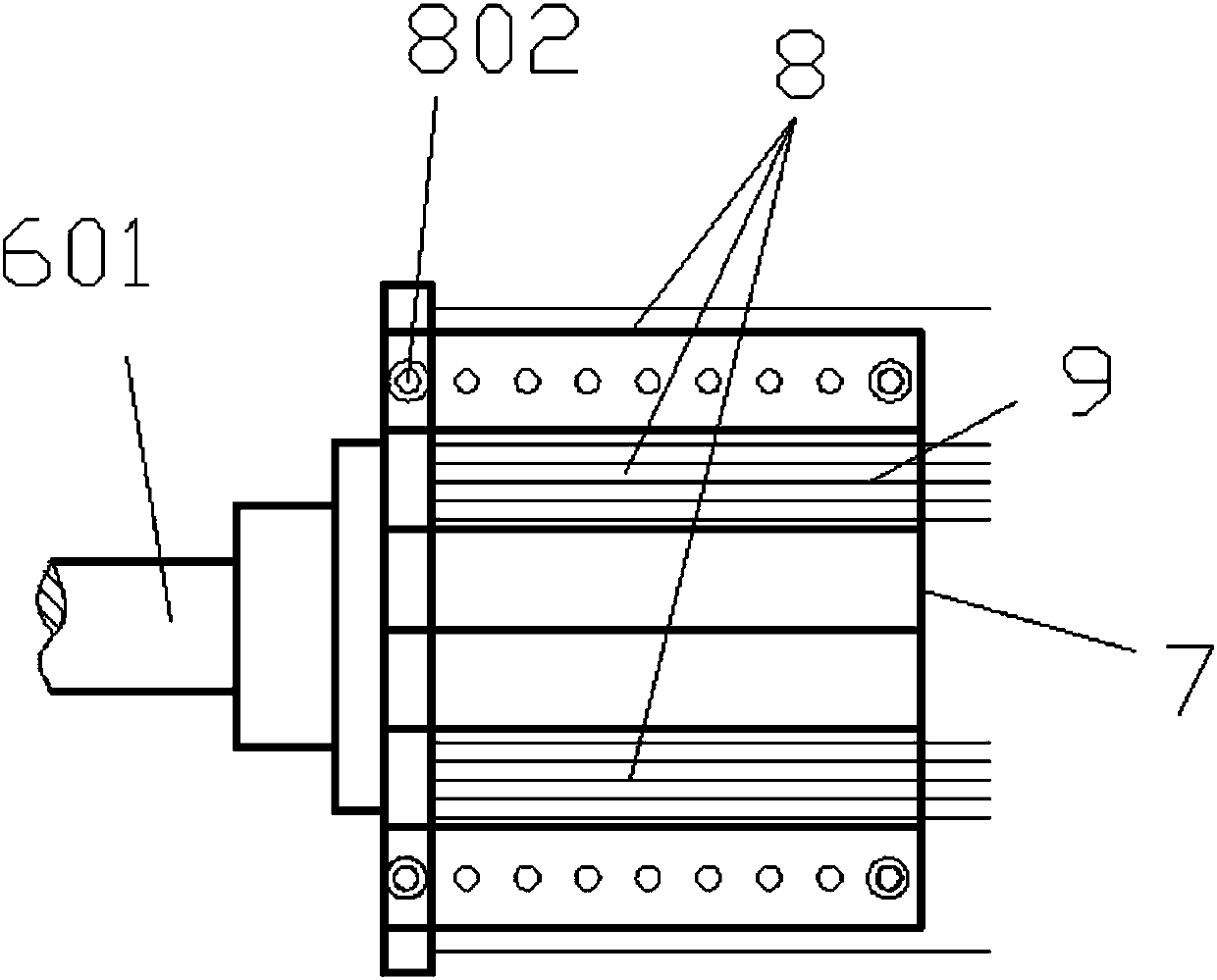

[0023] Attached below Figure 1-7 An embodiment of the present invention is described.

[0024] The following examples facilitate a better understanding of the present invention, but do not limit the present invention. The implementation of the control circuit in the following embodiments is a conventional control method unless otherwise specified. The components used in the following examples are commercially available unless otherwise specified.

[0025] Robots used for loading and unloading materials in the toothbrush production line, (such as figure 1 As shown) has a PLC control cabinet 1, a working platform 2 is installed on one side of the PLC control cabinet 1, and the working platform 2 is a box-type structure. The upper end of the working platform 2 is equipped with a column rotary cylinder 3, and the column rotary cylinder 3 The free end is connected to the lifting cylinder 4, and the lifting free end of the lifting cylinder 4 is connected to the telescopic cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com