Negative-pressure liquefied gas preparation process

A technology of liquefied gas and preparation technology, which is applied to equipment discharged from pressure vessels, pressure vessels, mechanical equipment, etc., which can solve problems such as energy consumption, low mixing efficiency of air and oil, and increased equipment complexity, etc., to achieve reduction Volume, reduce energy consumption, improve the effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

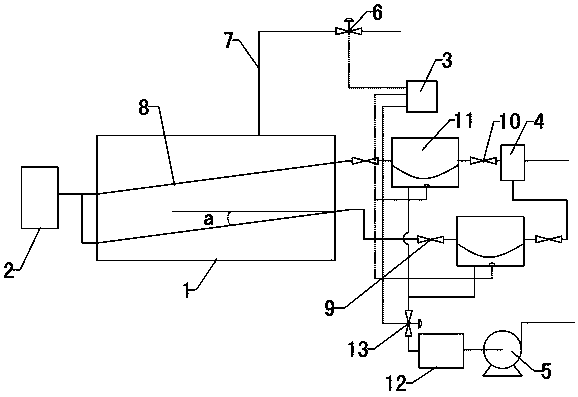

[0025] Holes with a diameter of 1.0mm are evenly distributed on the oil-gas mixing tube 8, and the density of the holes on the oil-gas mixing tube 8 is 3 pcs / cm 2 The wall thickness of the oil-gas mixing tube 8 is 2.5mm; the oil-gas mixing tube 8 is inclined upward from the air inlet end to the other end, and the inclination angle a between the oil-gas mixing tube 8 and the horizontal plane is 10°;

[0026]After the vacuum pump 5 is turned on, the negative pressure buffer box 12 forms a negative pressure. The controller 3 controls each negative pressure pipe electromagnetic valve 13 to open at a certain time interval. The gas is extracted alternately, the space is reduced, and the space in each gas chamber becomes larger, the pressure decreases, the front check valve 9 is opened, and a negative pressure airflow is formed in the oil-gas mixing pipe 8, and air is sucked into the air filter 2 At the same time, the holes on the oil-gas mixing tube 8 suck in liquid light hydrocarbo...

Embodiment 2

[0028] Holes with a diameter of 0.8 mm are evenly distributed on the oil-gas mixing tube 8, and the density of the holes on the oil-gas mixing tube 8 is 4 pcs / cm 2 The wall thickness of the oil-gas mixing tube 8 is 3mm; the oil-gas mixing tube 8 is inclined upward from the inlet end to the other end, and the inclination angle a between the oil-gas mixing tube 8 and the horizontal plane is 12°;

[0029] After the vacuum pump 5 is turned on, the negative pressure buffer box 12 forms a negative pressure. The controller 3 controls each negative pressure pipe electromagnetic valve 13 to open at a certain time interval. The gas is extracted alternately, the space is reduced, and the space in each gas chamber becomes larger, the pressure decreases, the front check valve 9 is opened, and a negative pressure airflow is formed in the oil-gas mixing pipe 8, and air is sucked into the air filter 2 At the same time, the holes on the oil-gas mixing tube 8 suck in liquid light hydrocarbons a...

Embodiment 3

[0031] Holes with a diameter of 0.5 mm are evenly distributed on the oil-gas mixing tube 8, and the density of the holes on the oil-gas mixing tube 8 is 5 pcs / cm 2 The wall thickness of the oil-gas mixing tube 8 is 2 mm; the oil-gas mixing tube 8 is inclined upward from the inlet end to the other end, and the inclination angle a between the oil-gas mixing tube 8 and the horizontal plane is 10°;

[0032] After the vacuum pump 5 is turned on, the negative pressure buffer box 12 forms a negative pressure. The controller 3 controls each negative pressure pipe electromagnetic valve 13 to open at a certain time interval. The gas is extracted alternately, the space is reduced, and the space in each gas chamber becomes larger, the pressure decreases, the front check valve 9 is opened, and a negative pressure airflow is formed in the oil-gas mixing pipe 8, and air is sucked into the air filter 2 At the same time, the holes on the oil-gas mixing tube 8 suck in liquid light hydrocarbons ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com