Part for clock movement

A clock movement and outer surface technology, applied in the field of fork shaft, escapement pinion, non-magnetic pivoting mandrel and pendulum shaft, can solve the problems of difficult machining of pivoting mandrel, high cost, expensive alloy, etc. To achieve the effect of good chemical resistance, improved friction performance, good mechanical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In this specification, the term "non-magnetic" refers to a paramagnetic or diamagnetic or antiferromagnetic material having a magnetic permeability lower than or equal to 1.01.

[0034] An alloy of an element is an alloy comprising at least 50% by weight of that element.

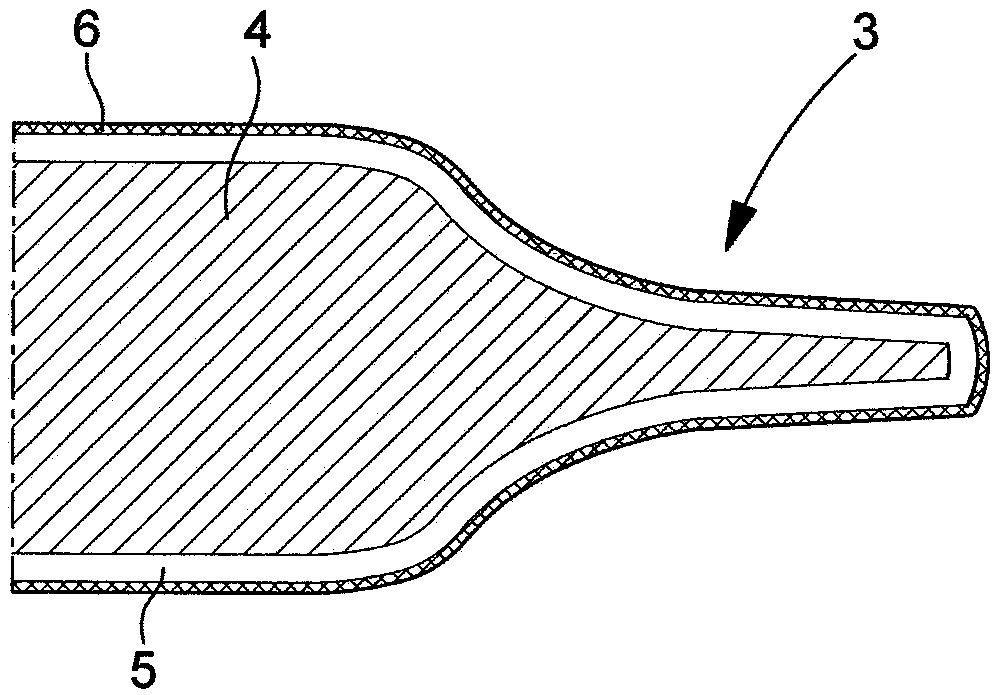

[0035] The present invention relates to a component for a timepiece movement, and in particular to a non-magnetic pivoting arbor for a mechanical timepiece movement.

[0036] The invention will be described below with reference to the application of a non-magnetic balance shaft 1 . Of course, other types of timepiece pivot arbors are also conceivable, such as a timepiece wheel set arbor, typically an escapement pinion or a fork. Such a component has a body with a diameter of preferably less than 2 mm and a pivot with a diameter of preferably less than 0.2 mm, with an accuracy of a few micrometers.

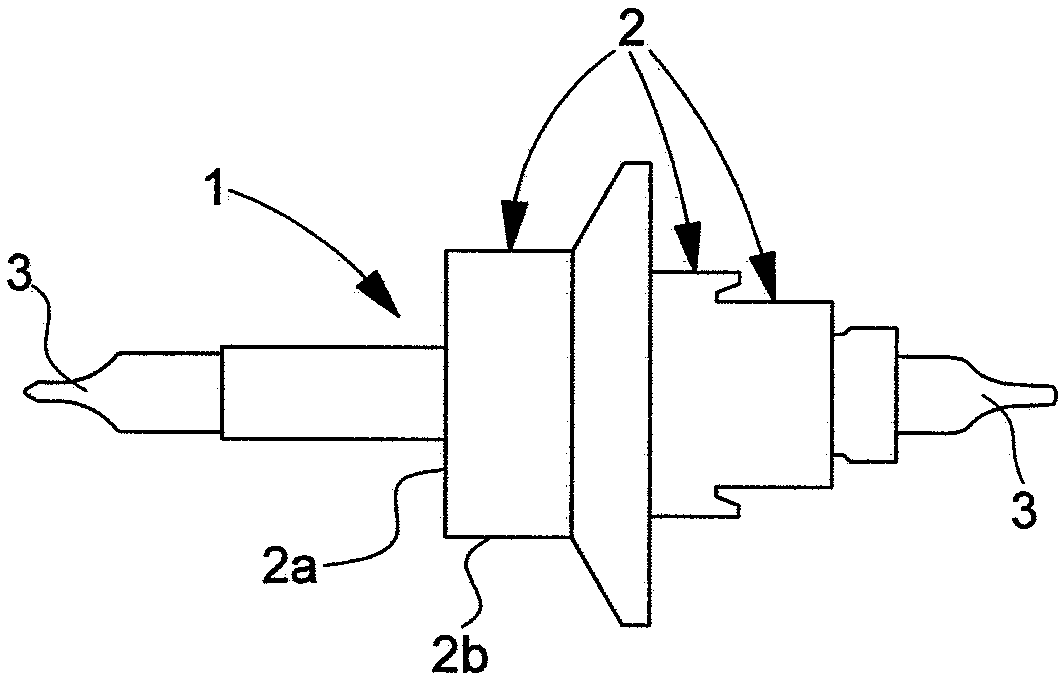

[0037] refer to figure 1 , which shows a pendulum 1 according to the invention comprising a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com