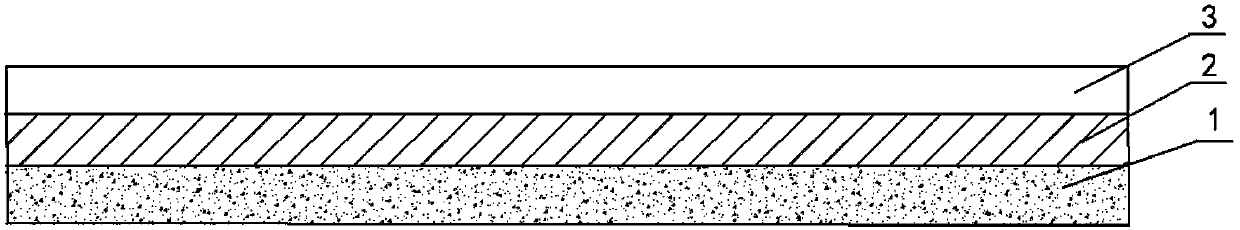

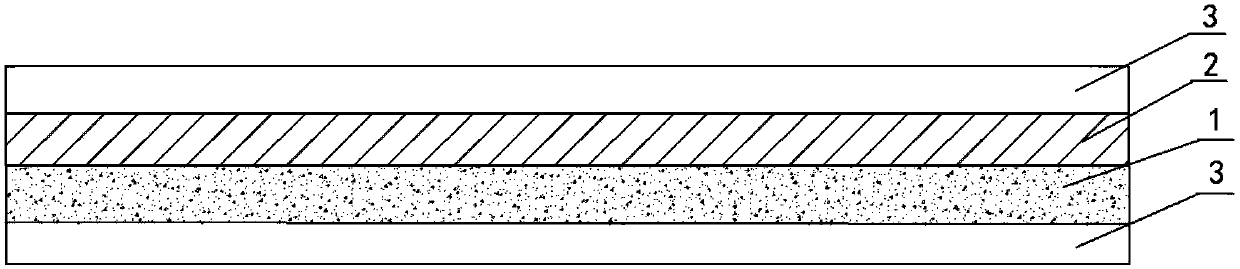

Graphene silver nanowire composite flexible heat-emitting film assembly

A technology of silver nanowire and heating film, which is applied in the direction of heating element materials, electric heating devices, electrical components, etc., can solve the problems of non-antibacterial, etc., and achieve the effects of good heating stability, stable surface temperature, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The present embodiment is used to prepare the graphene-silver nanowire composite flexible heating film, and the raw materials used are as follows:

[0072] Graphene powder: particle size is 4-5μm, from Hefei Microcrystalline Materials Technology Co., Ltd., available in the market;

[0073] Silver nanowire dispersion: the concentration is 5mg / mL, which is from Hefei Microcrystalline Materials Technology Co., Ltd. and can be purchased in the market. The diameter of the silver nanowires contained in it is 60-70nm and the length is 30-40μm;

[0074] Conductive carbon black: particle size is 9-17nm, Tianjin Yiborui Chemical Co., Ltd., brand F900A;

[0075] Waterborne polyurethane resin: 50% solid content, Dongguan Mirenzhan Chemical Co., Ltd., grade MR-709;

[0076] Water-based epoxy resin: 50% solid content, Guangdong Shunde Dadiyuan New Material Co., Ltd., brand DRDSE560;

[0077] Water-based acrylic resin: 50% solid content, Guangdong Shunde Dadiyuan New Material Co., L...

Embodiment 2

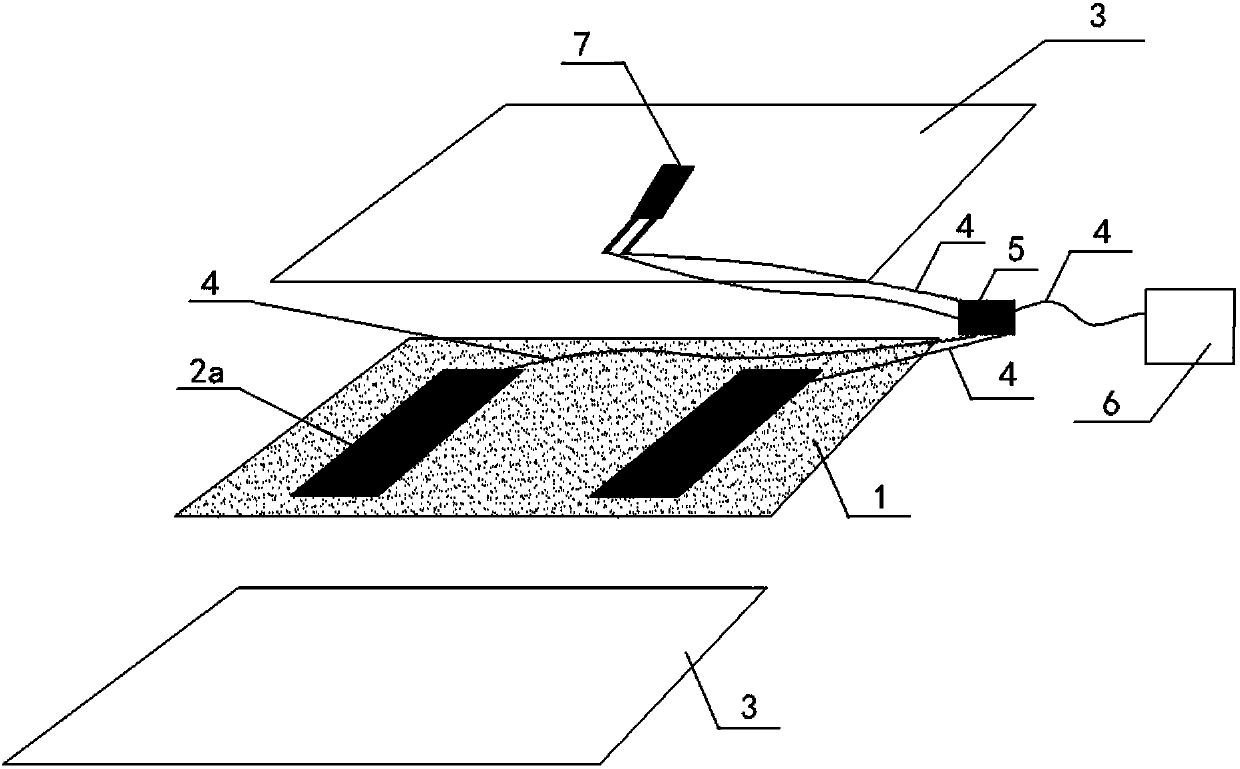

[0096] The electrode material of the present invention can take different forms, such as metal foil, conductive cloth, conductive tape and conductive paste, etc. The different forms of electrodes will also have an impact on the heating film assembly, as follows:

[0097] When using the interdigital electrode in the form of conductive silver paste, it is processed as follows: first, the electrode pattern is drawn through cad, and then a screen printing plate is made, and the electrode area needs to be hollowed out and alignment marks are made; The graphene-silver nanowire composite flexible heating film is cut into the desired size and shape; the conductive silver paste is screen printed on the graphene-silver nanowire composite flexible heating film, and then cured at 150 ° C for 1 hour to form an electrode layer (The actual picture is as Image 6 shown); riveted the conductive wire on the electrode of the heating film by the end punching machine (the actual picture is shown i...

Embodiment 3

[0104] When the electrode layer is an interdigitated electrode structure, if the distance between the extension terminal of the current collector bar and another current collector bar is too small, local hot spots will occur, and if the distance is too large, the excessively large area will not generate heat, thus affecting the heating performance. Therefore, the present invention solves this problem by arranging the form of a through hole between the extension terminal of the current collecting bar and another current collecting bar. like Figure 8 As shown, A is the infrared image of the heating film with unprocessed through-holes under 5V voltage, and B is the infrared image of the heating film with processed through-holes under 5V voltage. After testing, the resistances of the two are basically the same. It can be seen that a local hot spot is generated between the extension terminal of the collector strip and another collector strip in Figure A, while there is no hot spot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com