Method of preparing for re-operation of reactor for growing epitaxial wafer

A wafer and reaction chamber technology, applied in the field of heavy operation preparation process, can solve problems such as difficulty in ensuring the quality of epitaxial wafers, and achieve the effect of reducing preparation time and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Although the embodiments have been described in detail with reference to the drawings, the present disclosure is not limited to the embodiments. Also, detailed descriptions related to known functions or configurations will be omitted to avoid unnecessarily obscuring the subject matter of the present disclosure.

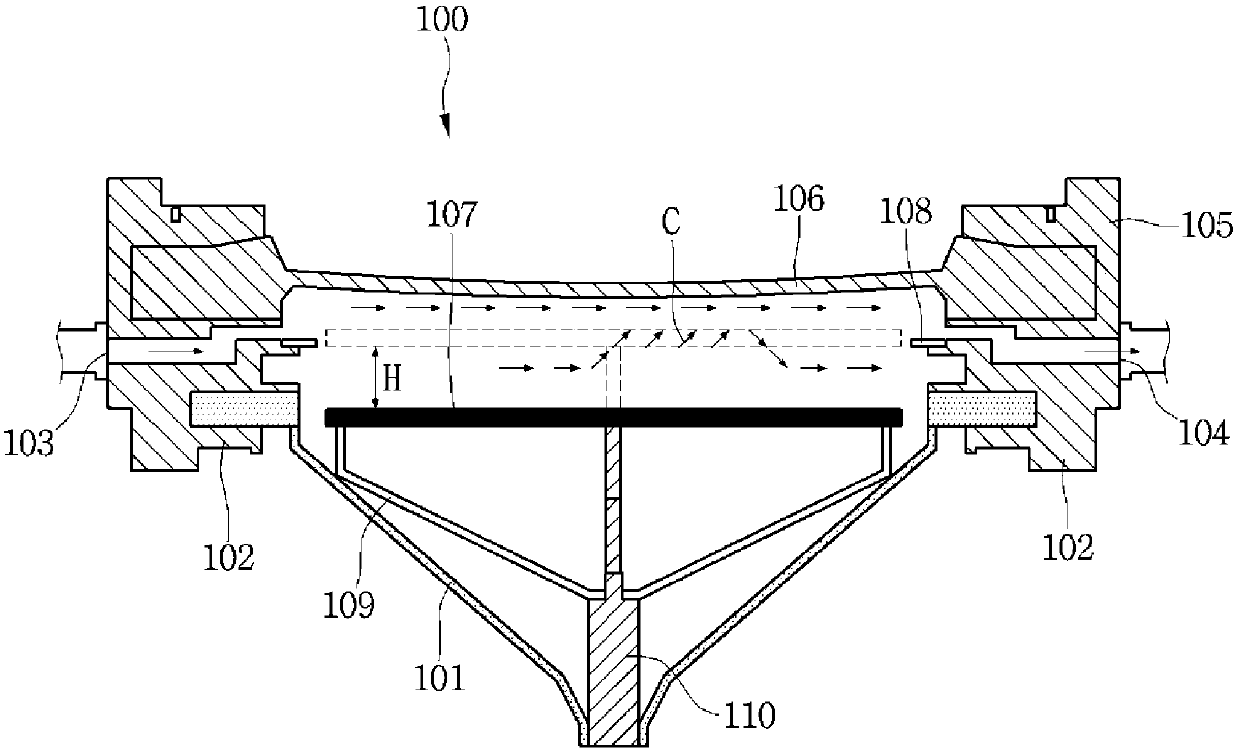

[0022] Embodiments provide a method in which process conditions and pedestal positions in an epitaxial reactor (reactor) are changed such that stagnant contaminants in the lower part of the epitaxial reactor move upwards, creating an upflow.

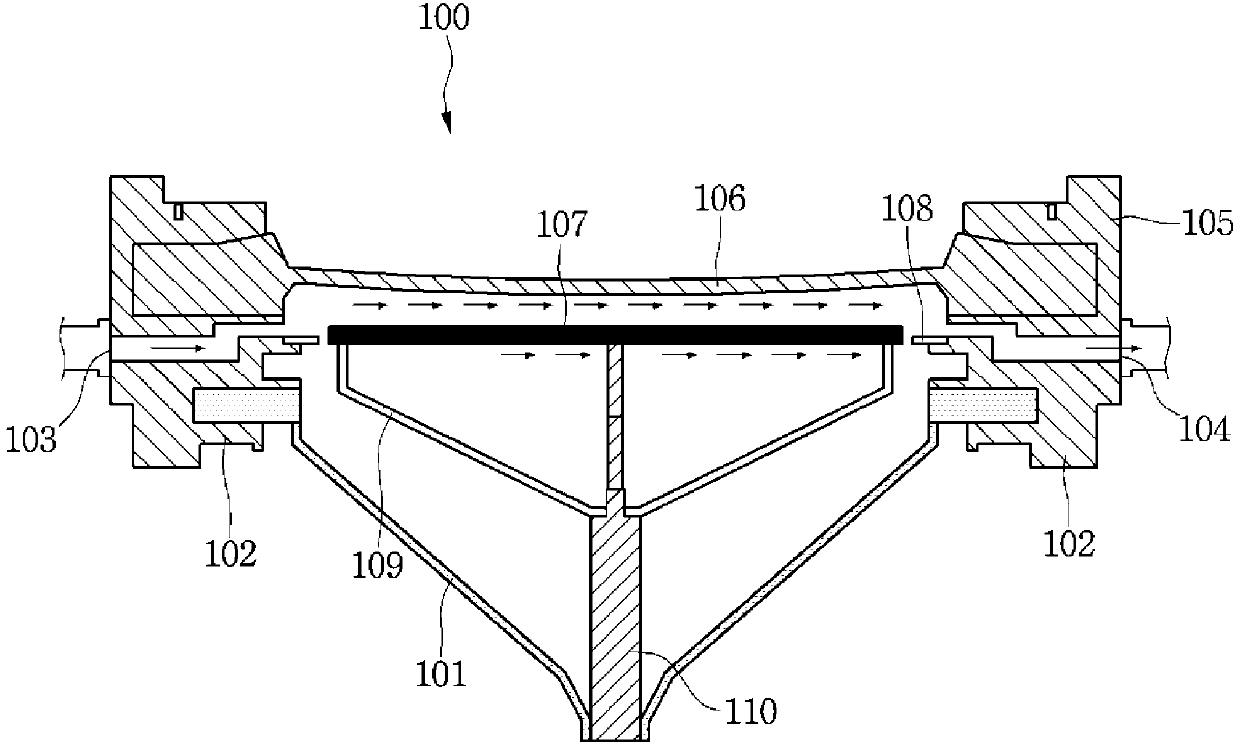

[0023] figure 1 is a view of the epitaxial growth device, that is, a schematic cross-sectional view showing the first position of the susceptor when the baking process is performed in the processing chamber.

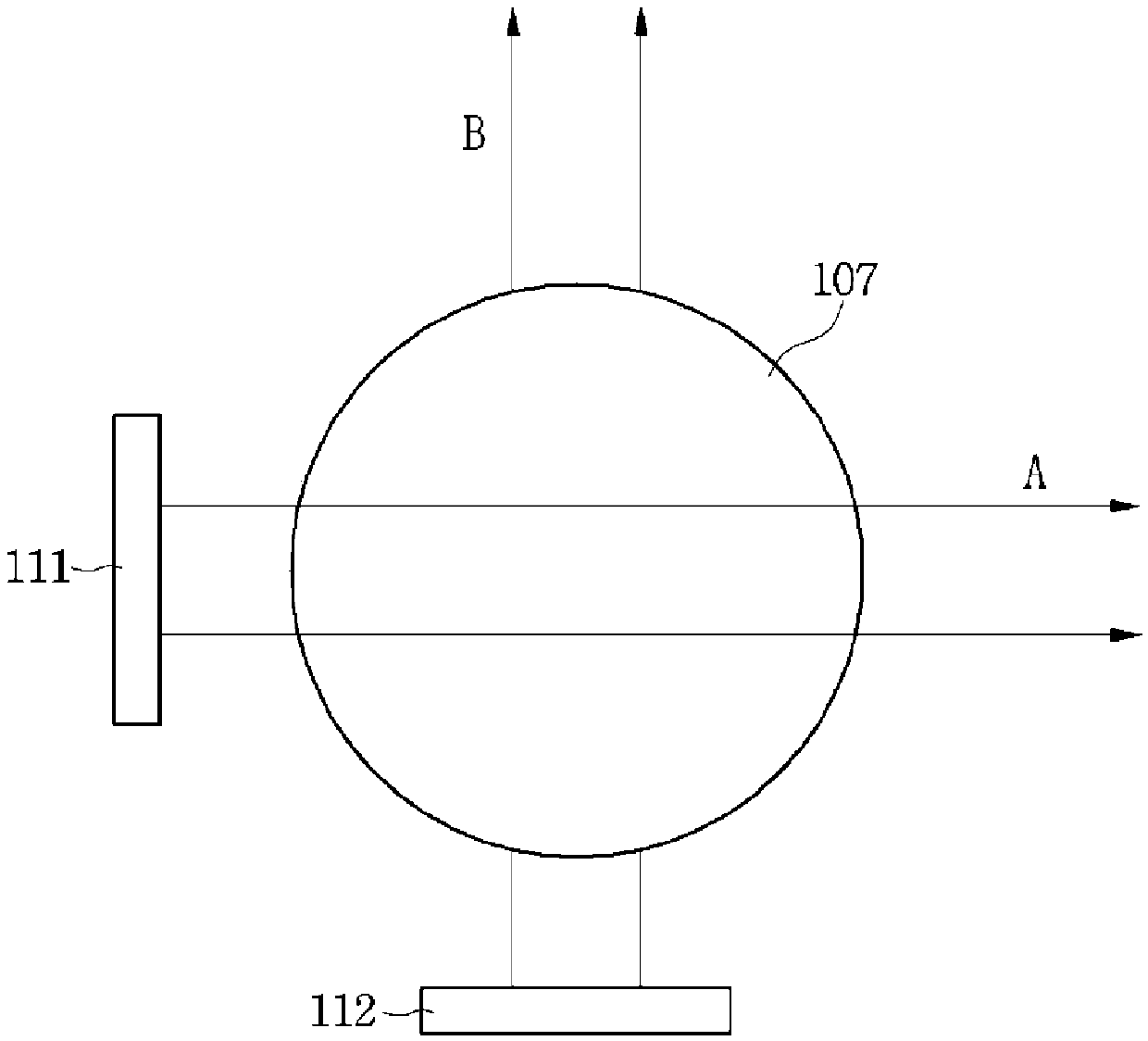

[0024] refer to figure 1 , the epitaxial growth apparatus 100 may include: an upper liner 105, a lower liner 102, an upper cover 106, a lower cover 101, a base 107, a preheating ring 108, a base support 109, an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com