Nursery greenhouse beneficial to nursery stock growth

A greenhouse and nursery technology, applied in the field of nursery Dapeng, can solve the problems of insufficient comprehensiveness, high cost, slow growth of seedlings, etc., and achieve the effects of reasonable structure design, labor intensity saving, and good growth of seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

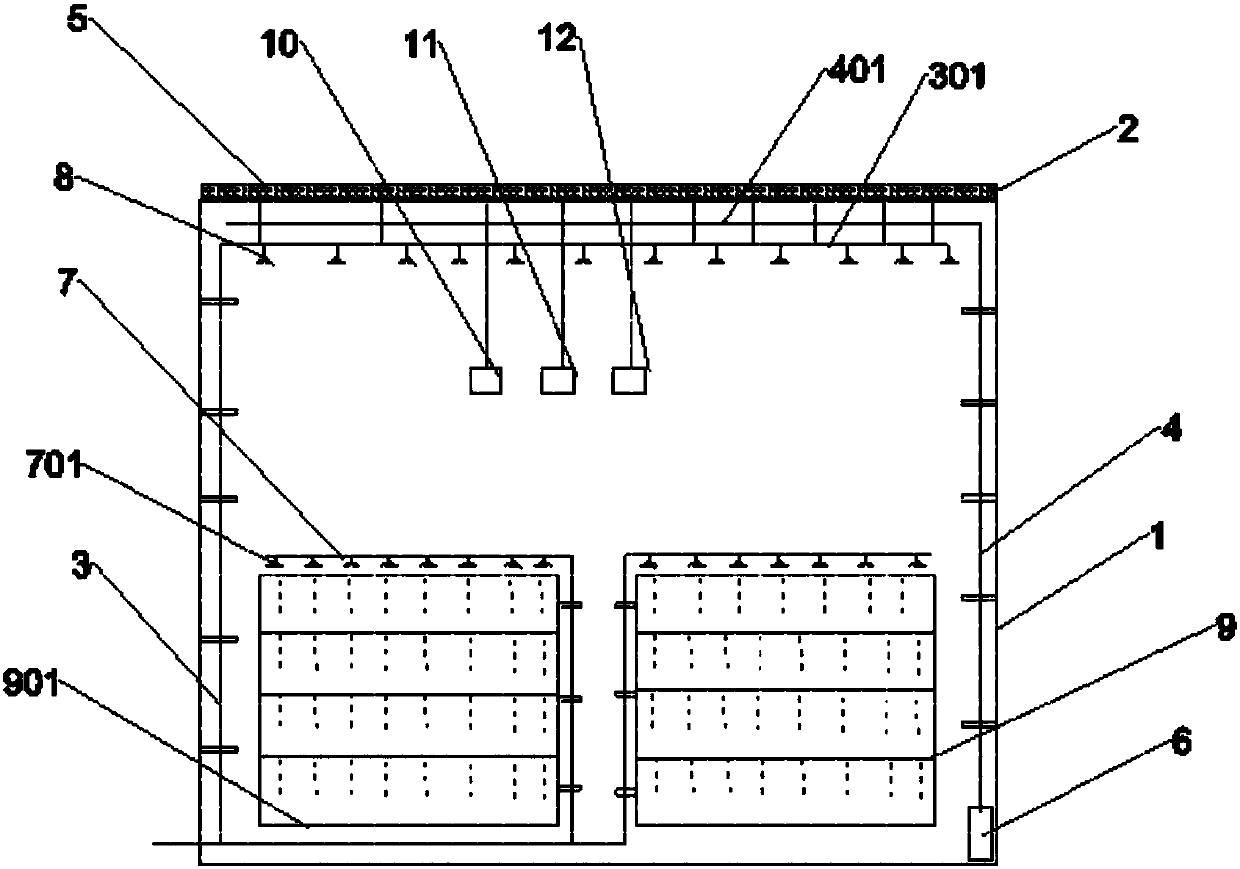

[0018] A kind of nursery greenhouse that is beneficial to the growth of seedlings, comprising a greenhouse body 1 and at least one group of water spray pipes 7, spray water pipes 301, flue gas pipes 401 and seedling raising racks 9 arranged in the greenhouse body 1; the top cover of the greenhouse body 1 is Transparent glass cover 2; two layers of seedling beds 901 are arranged at least on the seedling raising frame 9, some water outlet holes are arranged at the bottom of the seedling raising bed 901, and one layer of cotton water-absorbing layer is arranged at the bottom of the seedling raising bed 901, and the water spray pipe 7 is provided with Above the seedling raising frame 9, and the water spray pipe 7 is provided with several spray heads 701; the spray water pipe 301 and the flue gas pipe 401 are fixed on the top of the greenhouse body 1 by a fixing frame, and the spray water pipe 301 is provided with a plurality of spray heads 8. A number of air outlets are provided on...

Embodiment 2

[0021] Further optimization is carried out on a kind of nursery greenhouse that is beneficial to the growth of seedlings described in Embodiment 1. In this embodiment, the water spray pipe 7 and the spray water pipe 301 are respectively connected to the water inlet pipe 3, and the water inlet pipe 3 is respectively connected by buckles. Be fixed on the greenhouse body 1 side wall and the seedling raising frame 9 side walls. The setting of water inlet pipe 3 is conducive to providing water for water spray pipe 7 and spray pipe 8, and water inlet pipe 3 is fixed on the side wall by buckle and is conducive to the fixing of water inlet pipe 3, and is convenient for disassembly and maintenance.

Embodiment 3

[0023] Further optimization is carried out on a kind of nursery shed that is beneficial to the growth of seedlings described in Embodiment 1. In this embodiment, the flue gas pipe 401 is connected to the air inlet pipe 4, and the lower end of the air inlet pipe 4 extends into the gas mixing chamber 6. The gas mixing chamber 6 is used for mixing flue gas and cold air, and the air inlet pipe 4 is fixed on the side wall of the greenhouse body 1 by buckling. The setting of the mixing chamber 6 is conducive to the mixing of flue gas and cold air. The concentration and temperature of CO2 in the flue gas are relatively high, which can be neutralized by mixing with the cold air, and then enter the flue gas pipe 401, and at the same time provide the necessary temperature for the greenhouse and CO2 gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com