Composition and application thereof for catalyst removal of titanium series isoprene rubber

A technology of isoprene rubber and composition, applied in the field of polymer catalysts, can solve the problems of complex process, environmental pollution, thermal oxidation performance and processing application performance of dry rubber, large influence, etc., and achieves high removal efficiency and excellent processing and application. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

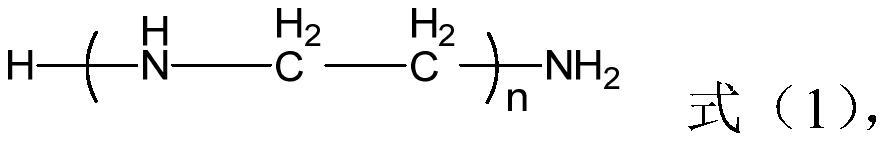

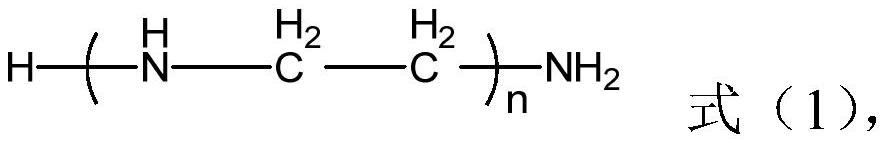

Method used

Image

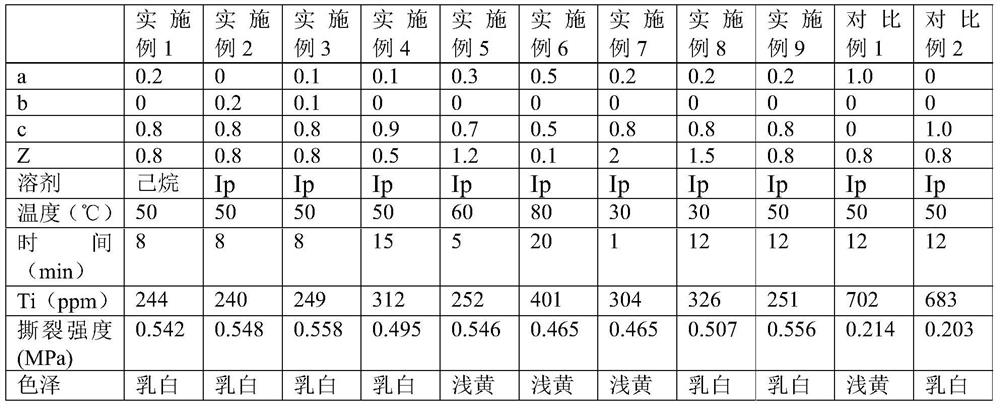

Examples

Embodiment approach 1

[0028] Embodiment 1: The composition includes triisopropanolamine and N,N-di(3-aminopropyl)ethylethylamine;

Embodiment approach 2

[0029] Embodiment 2: The composition includes tetraethylenepentamine and N,N-di(3-aminopropyl)ethylethylamine;

Embodiment approach 3

[0030] Embodiment 3: The composition includes triisopropanolamine, tetraethylenepentamine and N,N-di(3-aminopropyl)ethylethylamine.

[0031] Preferably, the content weight ratio of the component A to the N,N-bis(3-aminopropyl)ethylethylamine is 1:1-10; more preferably 1:2-4. The inventors of the present invention found in research that when the content weight ratio of the component A and the N,N-bis(3-aminopropyl)ethylethylamine is controlled to be 1:2-4, the present invention can be used The removal rate of the composition is higher when removing the titanium-based isoprene rubber catalyst.

[0032] Preferably, the composition further contains a solvent, and the composition is in the form of a solution.

[0033] Preferably, the solvent is at least one selected from organic solvents and inorganic solvents; more preferably, the organic solvent is selected from at least one of paraffins, cycloalkanes and olefins, and the inorganic solvent is water. Further preferably, the solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com