A kind of solvent-free graphene oxide-supported silica nano-fluid and its application

A silicon dioxide and fluid-like technology, which is applied in the direction of additives, petroleum industry, lubricating compositions, etc., to achieve the effects of enhancing strength, improving processing and application performance, and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

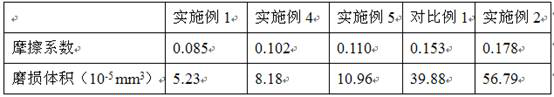

Examples

Embodiment 1

[0038]In parts by mass, 100 parts of silica nanoparticles (8 nm) were dispersed in a mixed solution of 550 mL of deionized water (50 mL) and ethanol (500 mL), ultrasonicated for 1 h, and 100 parts of % of 3-aminopropyltriethoxysilane surfactant, stirred and refluxed at 90 °C for 24 h, centrifuged at 10,000 rpm, washed with deionized water and ethanol, and dried in vacuum at 80 °C for 24 h to obtain surfactant-modified of silica nanoparticles. In parts by mass, 10 parts of graphene oxide were dispersed in 300 mL of deionized water, ultrasonically stripped for 2 h, 20 parts of modified silica nanoparticles were added, reacted at 80 °C for 12 h, and the product was centrifuged at 10,000 rpm and washed with deionized water Wash and purify with ethanol, and dry in vacuum at 80 °C for 24 h to obtain graphene oxide-supported silica nanoparticles; in parts by mass, take 20 parts of graphene oxide-supported silica nanoparticles and disperse them in 100 mL of deionized Sonicate in wate...

Embodiment 2

[0041] In parts by mass, 40 parts of silica nanoparticles (12 nm) were dispersed in a mixed solution of 300 mL of deionized water (20 mL) and ethanol (280 mL), ultrasonicated for 1 h, and 100 parts of % of 3-aminopropyltriethoxysilane surfactant, stirred and refluxed at 120 °C for 24 h, the product was centrifuged at 10,000 rpm, washed and purified with deionized water and ethanol, and dried in vacuum at 80 °C for 24 h to obtain surface active Agent-modified silica nanoparticles. In parts by mass, 10 parts of graphene oxide were dispersed in 300 mL of deionized water, ultrasonically stripped for 1 h, 40 parts of modified silica nanoparticles were added, reacted at 100 °C for 12 h, and the product was washed with deionized water and ethanol after centrifugation Purify and dry in vacuum at 80 °C for 24 h to obtain graphene oxide-supported silica nanoparticles; according to the mass fraction, take 10 parts of graphene oxide-supported silica nanoparticles, disperse them in 100 mL ...

Embodiment 3

[0043] In parts by mass, disperse 10 parts of silica nanoparticles (25 nm) in a mixed solution of 210 mL deionized water (10 mL) and ethanol (200 mL), sonicate for 1 h, and add 100 parts with a mass fraction of 65 % of 3-aminopropyltriethoxysilane surfactant, stirred and refluxed at 150 °C for 8 h, centrifuged at 10000 rpm, washed with deionized water and ethanol, and dried in vacuum at 80 °C for 24 h to obtain surfactant-modified Silica nanoparticles. In parts by mass, 10 parts of graphene oxide were dispersed in 300 mL of deionized water, ultrasonically stripped for 1 h, 150 parts of modified silica nanoparticles were added, reacted at 160 °C for 8 h, and the product was centrifuged at 10,000 rpm and washed with deionized water Wash and purify with ethanol, and vacuum-dry at 80 °C for 24 h to obtain graphene oxide-supported silica nanoparticles; in parts by mass, take 10 parts of graphene oxide-supported silica nanoparticles and disperse them in 100 mL deionized water , son...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com