A kind of solvent-free silicon dioxide nanometer fluid and its application

A silicon dioxide, fluid-like technology, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problem of no ceramic nano-particle fluid lubricants and lubricating oil additives publicly reported, etc., to improve processing and application performance, improve The effect of boundary lubrication performance, good anti-wear and anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

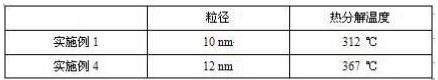

Embodiment 1

[0032] 1) Weigh 10 g of 30 wt% silica nanoparticle aqueous solution, disperse in 40 mL of deionized water, ultrasonicate for 30 minutes, adjust the pH of the solution to 9 with 2 mol / L sodium hydroxide, add 10.0 g of 50 wt% 3- (Trihydroxysilyl) propyl methylphosphonic acid monosodium salt aqueous solution, heated and stirred at 100°C for 24 hours, washed and purified to obtain phosphonate-modified silica nanoparticles. Disperse it in tetrahydrofuran solution, then add 40 mL of concentrated hydrochloric acid, stir and react at room temperature for 2 hours, centrifuge to remove sodium chloride salt, wash and spin dry the product, and obtain phosphonic acid-modified silica nanoparticles. Dissolve phosphonic acid-modified silica nanoparticles in deionized water, add 30 g of 70 wt% M2070 aqueous solution, heat and stir at 100 °C for 24 hours to obtain organic-modified silica nano-fluids. Wash and filter with deionized water, ethanol and tetrahydrofuran to remove impurities, then fu...

Embodiment 2

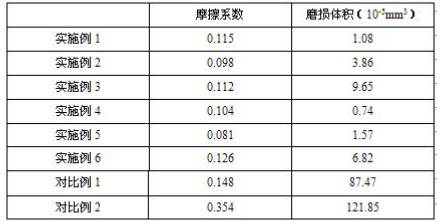

[0035] The silicon dioxide nano-fluid containing phosphonic acid functional groups obtained in Example 1 was used as an additive to the base oil polyethylene glycol PEG (Mw ~ 400), the addition amount was 5 wt%, and the lubricant was obtained by ultrasonic dispersion and dissolution to investigate its friction academic performance.

Embodiment 3

[0037] The silicon dioxide nano-fluid containing phosphonic acid functional groups obtained in Example 1 was used as the additive of the base oil polyalphaolefin PAO4, the addition amount was 5 wt%, and the lubricant was obtained by ultrasonic dispersion to investigate its tribological properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com