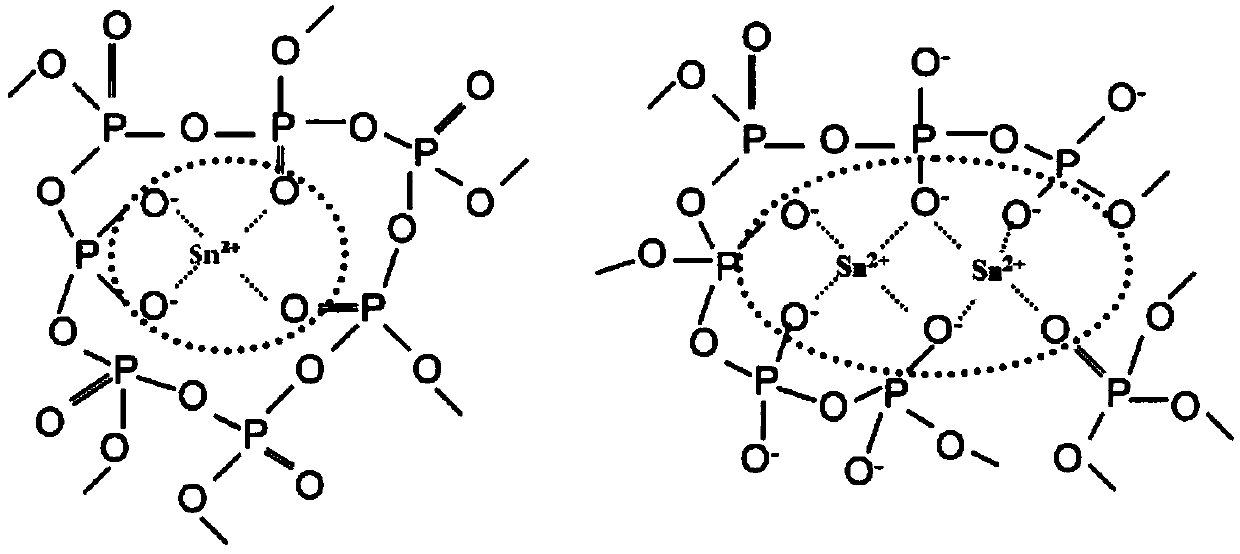

Phosphate-glass synergistic-effect halogen-free flame-retardant nylon-6 composition and preparation method thereof

A phosphate glass, flame retardant nylon technology, applied in the phosphate glass synergistic halogen-free flame retardant nylon 6 composition and its preparation, the field of modified nylon 6, can solve the problems of high dosage, reduced mechanical properties, etc. Good properties, enhanced flame retardant performance, good barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

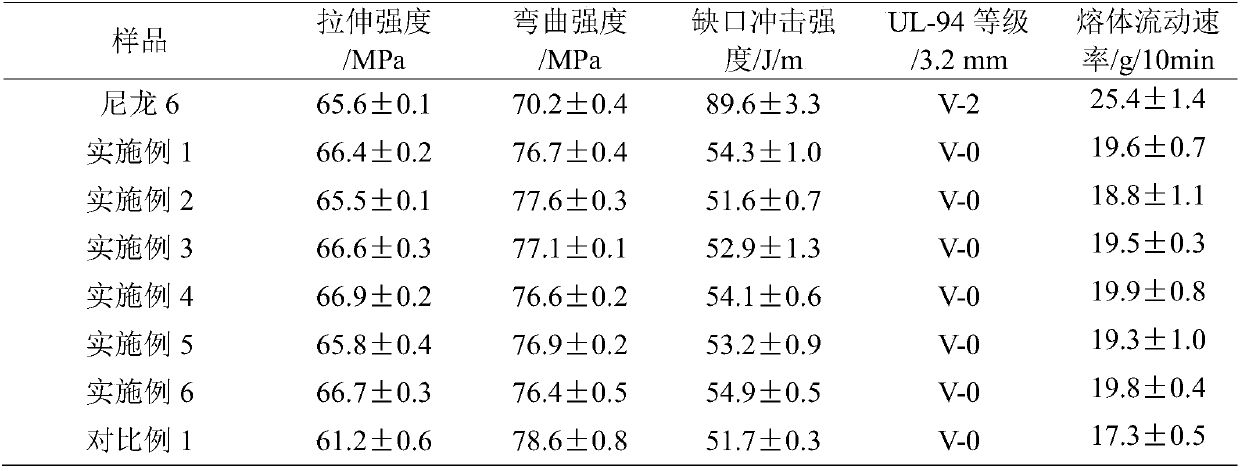

Embodiment 1

[0032] (1) Weigh 40.41g of stannous oxide and 42.60g of phosphorus pentoxide (molar ratio 50:50) and put them in a ceramic mortar, mix them evenly with a pestle and transfer them into a 200ml alumina ceramic crucible, and then put them Put it into another 500ml crucible, place excess carbon powder around the 200ml crucible to maintain a reducing atmosphere, cover it and place it in a muffle furnace at a temperature of 500°C for 60 minutes, take it out immediately, and pour the glass melt on an iron plate while it is hot Quenched on the top, pulverized by a high-speed pulverizer to obtain phosphate glass powder, measured T g is 123°C;

[0033] (2) At room temperature, add 2 g of melamine to 200 g of ethanol, and mix ultrasonically for 20 minutes to obtain a dispersion; heat the dispersion to 78° C., add 15 g of phosphate glass powder prepared in step (1), and mix at this temperature and 260 r React for 12 hours at a stirring rate of 1 / min, filter while hot, wash with ethanol, an...

Embodiment 2

[0036] (1) Weigh 32.33g of stannous oxide and 51.12g of phosphorus pentoxide (molar ratio 40:60) and put them in a ceramic mortar, mix them evenly with a pestle and transfer them to a 200ml alumina ceramic crucible, and then put them Put it into another 500ml crucible, place excess carbon powder around the 200ml crucible to maintain a reducing atmosphere, cover it and place it in a muffle furnace at a temperature of 500°C for 60 minutes, take it out immediately, and pour the glass melt on an iron plate while it is hot Quenched on the top, pulverized by a high-speed pulverizer to obtain phosphate glass powder, measured T g 55°C;

[0037] (2) At room temperature, add 5 g of melamine to 300 g of ethanol, and ultrasonically mix for 30 minutes to obtain a dispersion; the dispersion is heated to 78° C., and 15 g of the phosphate glass powder prepared in step (1) is added. React at a stirring rate of 1 / min for 20 hours, filter while hot, wash with ethanol and dry in a vacuum oven at...

Embodiment 3

[0040] (1) Weigh 48.49g of stannous oxide and 34.08g of phosphorus pentoxide (molar ratio 60:40) and put them in a ceramic mortar, mix them evenly with a pestle and transfer them to a 200ml alumina ceramic crucible, and then put Put it into another 500ml crucible, place excess carbon powder around the 200ml crucible to maintain a reducing atmosphere, cover it and place it in a muffle furnace at a temperature of 500°C for 60 minutes, take it out immediately, and pour the glass melt on an iron plate while it is hot Quenched on the top, pulverized by a high-speed pulverizer to obtain phosphate glass powder, measured T g is 183°C;

[0041] (2) At room temperature, add 1 g of melamine to 200 g of ethanol, and mix ultrasonically for 10 minutes to obtain a dispersion; heat the dispersion to 78° C., add 15 g of phosphate glass powder prepared in step (1), and mix at this temperature and 280 r React at a stirring rate of 1 / min for 6 hours, filter while hot, wash with ethanol and dry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com