Efficient seamless stone lawn construction technology

A construction technology and seamless stone technology, applied in the field of building manufacturing, can solve problems such as difficult construction quality assurance, difficulty in large-scale promotion of technology, complex process flow, etc., to achieve simple and convenient post-maintenance, simple and easy technology, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

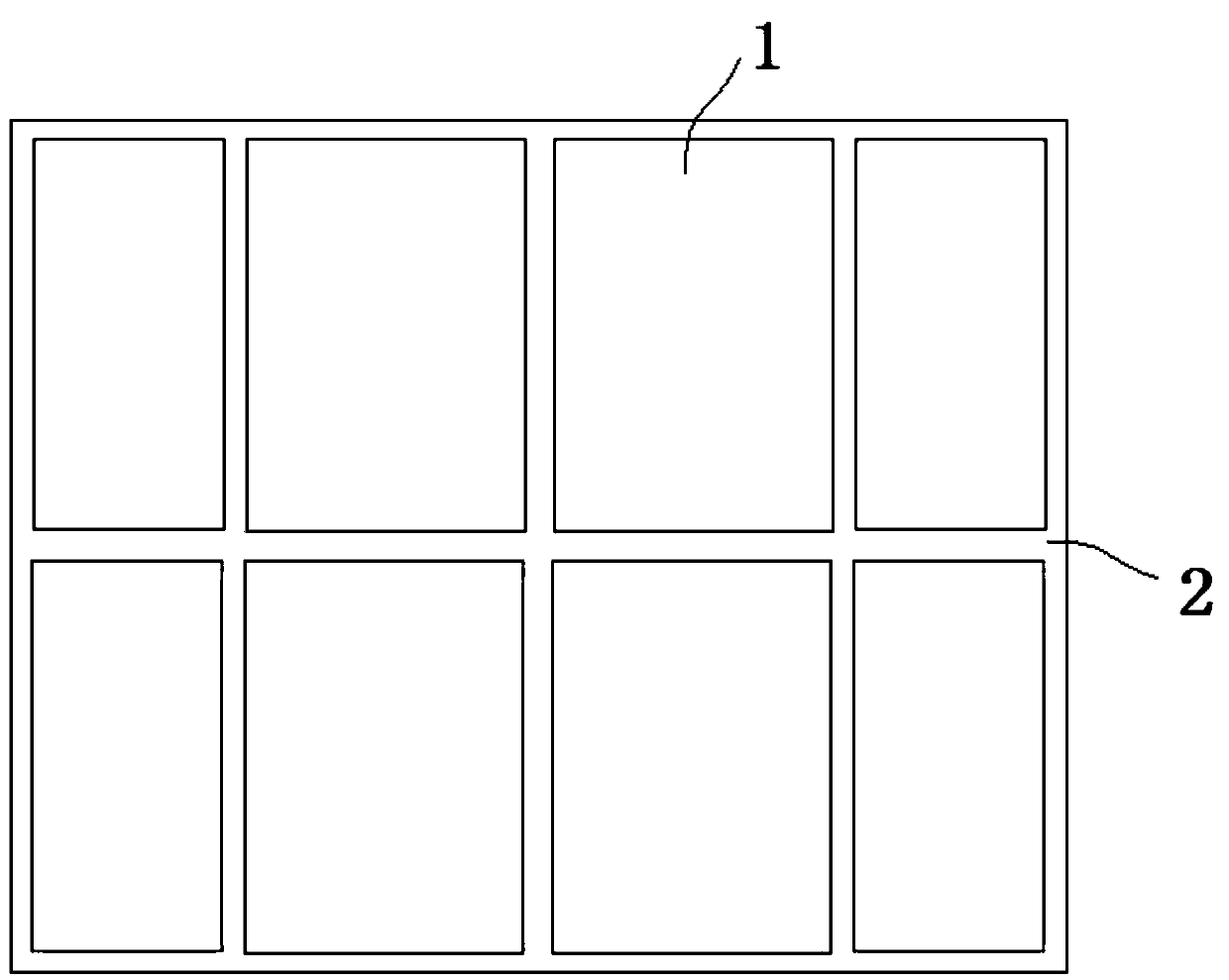

[0048] Such as figure 1 Shown, a kind of high-efficiency seamless stone floor construction technique, hard plate 1 is white granite, comprises the following steps:

[0049] Base surface treatment: surface cleaning, ground grinding, ground roughening, primer coating, and ground leveling of the ground in the construction area.

[0050] Hard board 1 pavement: draw the board laying position on the ground of the construction area, the interval between adjacent board laying positions is 20mm, and use resin adhesive to bond the hard board 1 to the board laying position, so The surrounding space of the hard board 1 is filled with the composite soft stone floor material 2 corresponding to the hard board 1 , the coverage area of the hard board 1 is 90%, and the total coverage area of the spacer is 10%.

[0051] Filling the stone-level composite soft material: filling the stone-level composite soft material into the interval around the hard plate 1, the stone-level composite soft ma...

Embodiment 2

[0057] Such as figure 1 Shown, a kind of efficient seamless stone floor construction technique, the kind of hard plate 1 is white marble, comprises the following steps:

[0058] Base surface treatment: surface cleaning, ground grinding, ground roughening, primer coating, and ground leveling of the ground in the construction area.

[0059] Hard board 1 pavement: draw the board laying position on the ground of the construction area, the interval between adjacent board laying positions is 50mm, use resin adhesive to glue the hard board 1 on the board laying position, hard The coverage area of the solid sheet 1 is 80% and the total coverage area of the spacer is 20%.

[0060] Filling stone-level composite soft material: filling composite soft filler into the interval around the hard plate 1, the composite stone-level composite soft material 2 is composed of 15% by mass of stone particle aggregate, 60% of stone powder , 12% polyurethane, 3% polyurethane curing agent, 6% auxil...

Embodiment 3

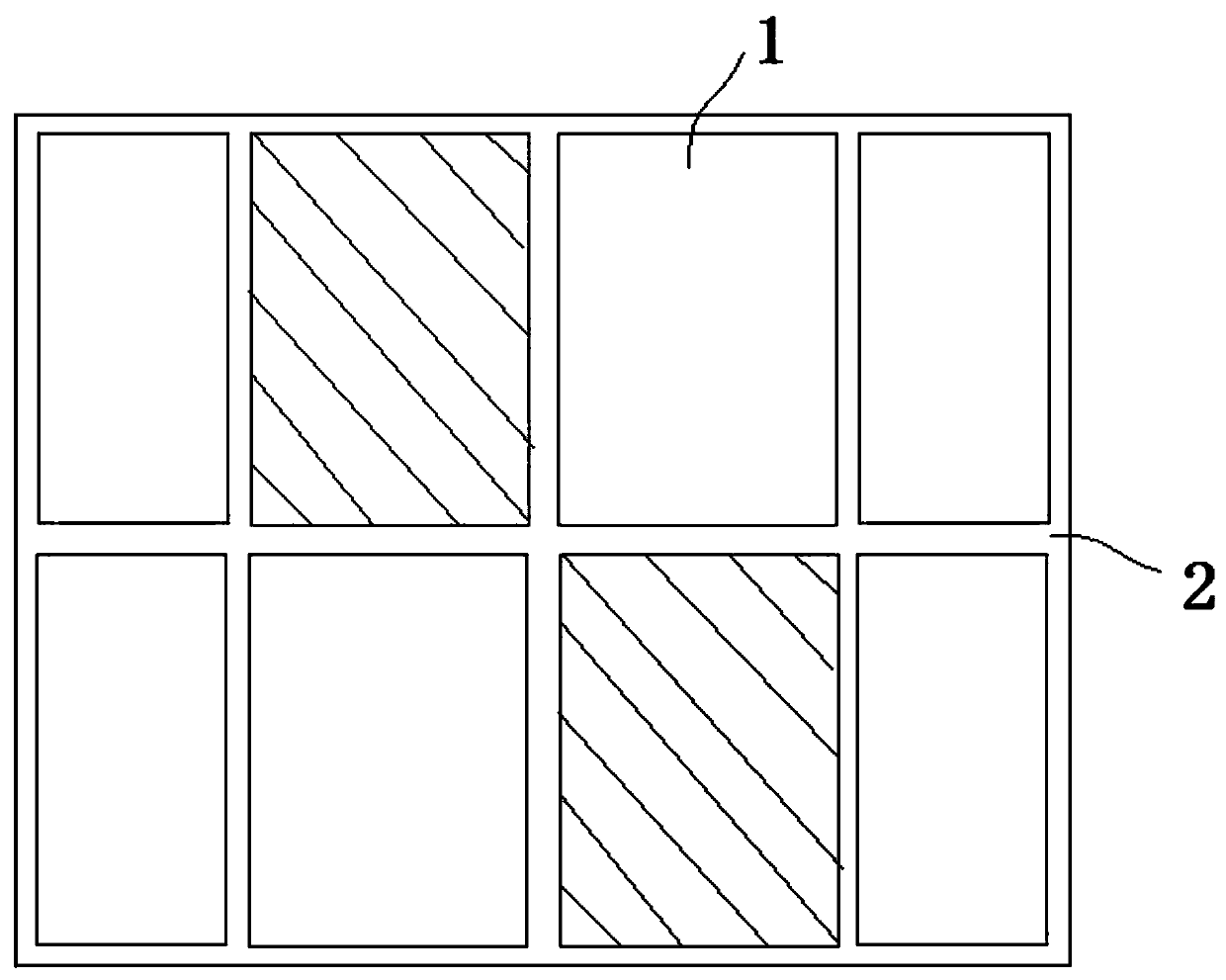

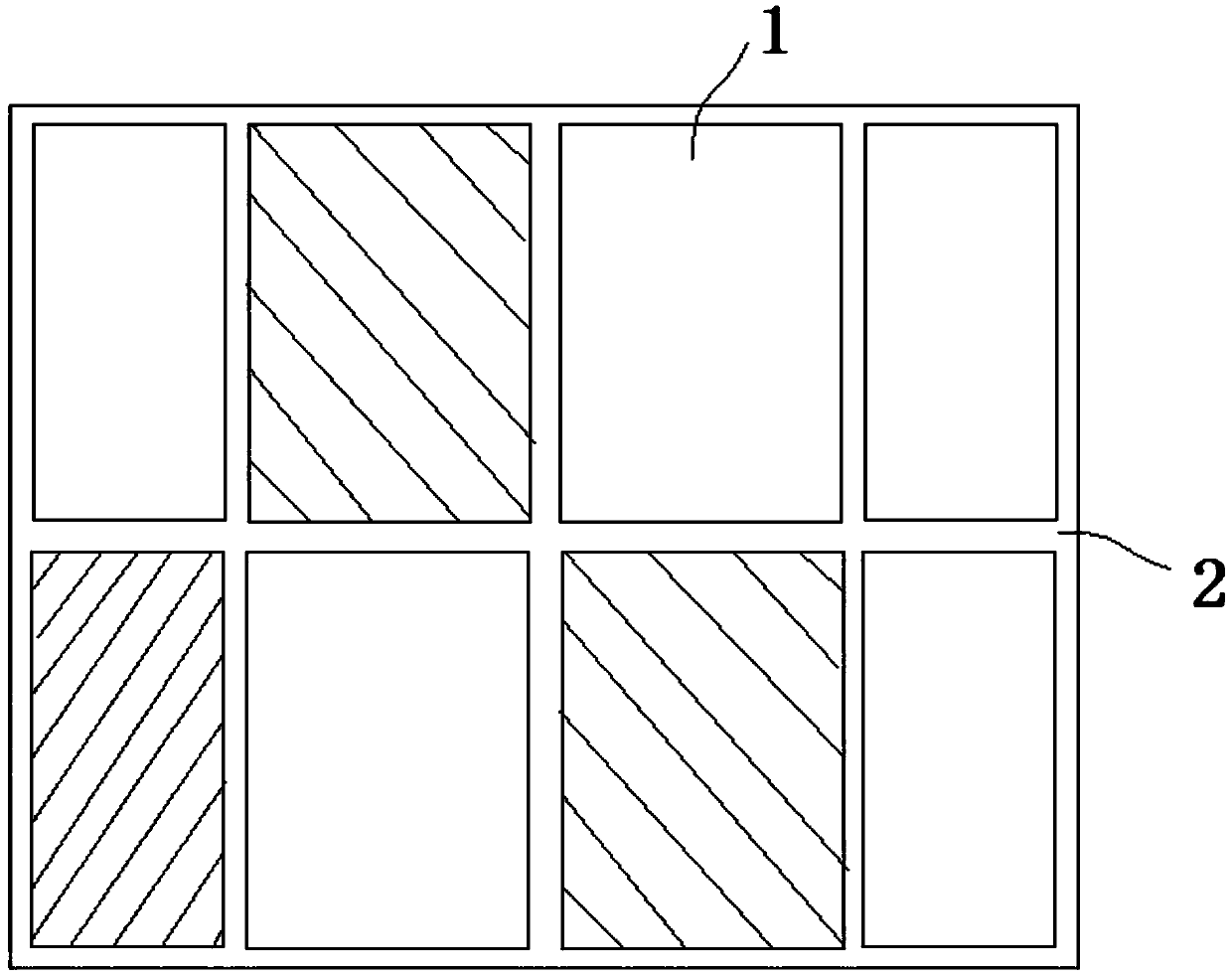

[0066] Such as figure 2 As shown, a kind of high-efficiency seamless stone floor construction technique, hard plate 1 comprises white granite and red granite, forms the stone floor with white as the base and red as the pattern, including the following steps:

[0067] Base surface treatment: surface cleaning, ground grinding, ground roughening, primer coating, and ground leveling of the ground in the construction area.

[0068] Hard slab 1 pavement: According to the horizontal and vertical coordinate axes of white granite and red granite in the design drawings, the corresponding horizontal and vertical distances on the ground in the construction area, the laying positions of hard slabs 1 of white granite and red granite are respectively Positioning is set on the ground in the construction area, and then the board laying position is drawn at the position set by the positioning. The interval between adjacent board laying positions is 300mm, and the hard board 1 is bonded to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap