A kind of method that reclaims selenium from silver cyanide mud

A technology for silver cyanide and selenium recovery, applied in the direction of element selenium/tellurium, can solve the problems of insufficient oxidation or volatilization of selenium, complicated control of process conditions, reduced selenium volatilization rate, etc., and achieves low cost, increased economic benefits, and improved recovery. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment includes the following steps:

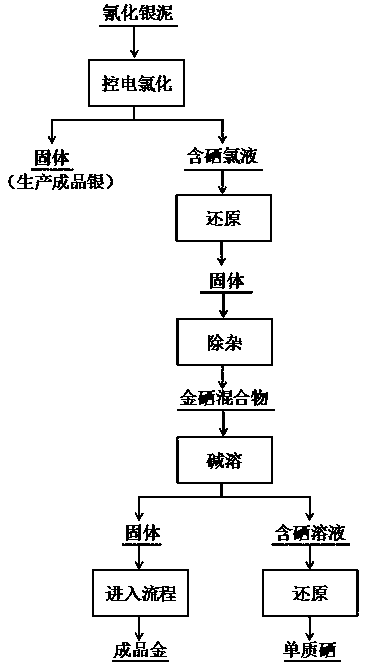

[0036] ① Electricity-controlled chlorination: Add silver cyanide mud into the reaction kettle, control the potential, make it chlorinated in the medium of sulfuric acid and salt, and make all the selenium and part of the gold enter the solution;

[0037] ②The first solid-liquid separation: the solid-liquid separation of the solution containing selenium and gold and the solid produced by chlorination;

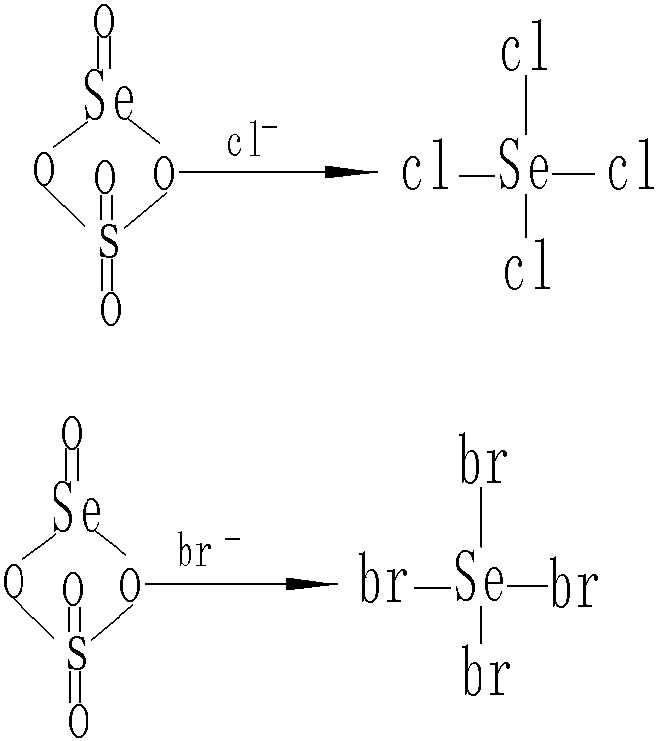

[0038] ③Reduction: Reduct the selenium-chlorine liquid after solid-liquid separation, add a reducing agent and a mixed catalyst of NaCl and NaBr to the selenium-chlorine liquid during reduction, the mixing ratio is 0.5, and react for 2 hours;

[0039] ④ Adsorption: Add ion exchange resin to the liquid containing gold and selenium for adsorption.

[0040] ⑤ Impurity removal: Add 6% dilute sulfuric acid to the elemental substance obtained after reduction and adsorption, and heat to 80°C for 80 minutes to remove impurities.

...

Embodiment 2

[0045] This embodiment includes the following steps:

[0046] ① Electricity-controlled chlorination: Add silver cyanide mud into the reaction kettle, control the potential, make it chlorinated in the medium of sulfuric acid and salt, and make all the selenium and part of the gold enter the solution;

[0047] ②The first solid-liquid separation: the solid-liquid separation of the solution containing selenium and gold and the solid produced by chlorination;

[0048] ③ Reduction: Reduct the selenium-chlorine liquid after solid-liquid separation, add a reducing agent and a mixed catalyst of NaCl and NaBr to the selenium-chlorine liquid during reduction, the mixing ratio is 1, and react for 2 hours;

[0049] ④ Adsorption: Add ion exchange resin to the liquid containing gold and selenium for adsorption.

[0050] ⑤ Impurity removal: Add 5% dilute sulfuric acid to the elemental substance obtained after reduction and adsorption, and heat to 80°C for 60 minutes to remove impurities;

...

Embodiment 3

[0055] This embodiment includes the following steps:

[0056] ① Electricity-controlled chlorination: Add silver cyanide mud into the reaction kettle, control the potential, make it chlorinated in the medium of sulfuric acid and salt, and make all the selenium and part of the gold enter the solution;

[0057] ②The first solid-liquid separation: the solid-liquid separation of the solution containing selenium and gold and the solid produced by chlorination;

[0058] ③Reduction: Reduct the selenium-chlorine liquid after solid-liquid separation, add a reducing agent and a mixed catalyst of NaCl and NaBr to the selenium-chlorine liquid during reduction, the mixing ratio is 1.5, and react for 2 hours;

[0059] ④ Adsorption: Add ion exchange resin to the liquid containing gold and selenium for adsorption.

[0060] ⑤ Impurity removal: Add 6% dilute sulfuric acid to the elemental substance obtained after reduction and adsorption, heat to 80°C, and the impurity removal time is 120 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com