Method for preparing edge-carboxylated graphene and graphene through reaction milling technology

A technology of carboxylated graphene and graphene, applied in chemical instruments and methods, graphene, carbon compounds, etc., can solve the problems of large pollution, high cost, and high risk, and achieve complete crystal structure, excellent water solubility, and electrical conductivity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Take out the ball mill tank of the planetary ball mill, add zirconia beads of 1 / 3 volume of the ball mill tank, and continue to add 200 mesh natural flake graphite powder until the total volume of zirconia beads and graphite powder reaches 1 / 2 of the total volume of the tank body, The ball mill jar is sealed, and carbon dioxide gas is charged into the ball mill jar until the pressure reaches 0.2 MPa, and then the gas is released, and this is repeated five times. Fill the ball mill jar with carbon dioxide gas until the pressure reaches 2MPa, close the air valve, and install the ball mill jar on the ball mill.

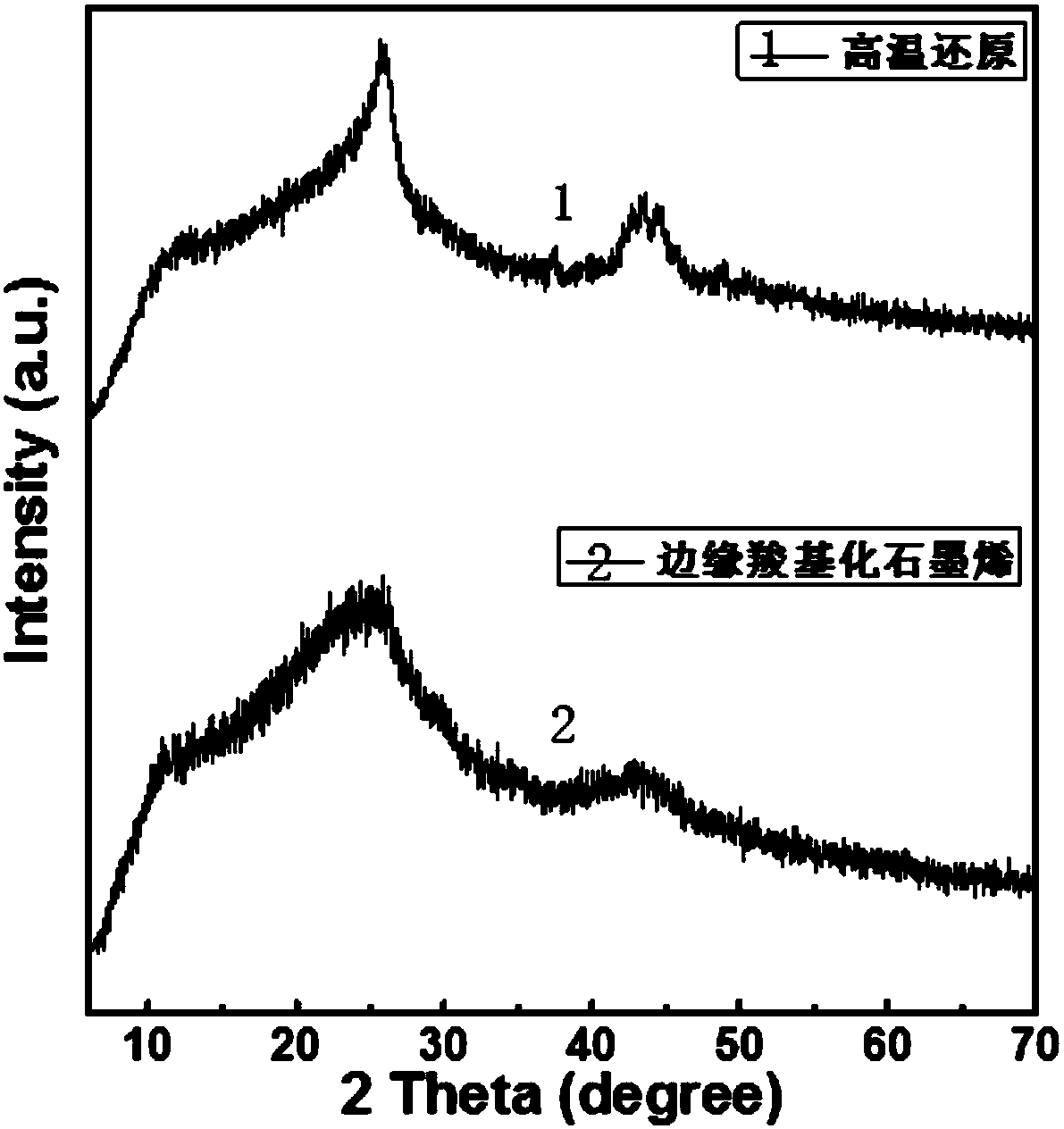

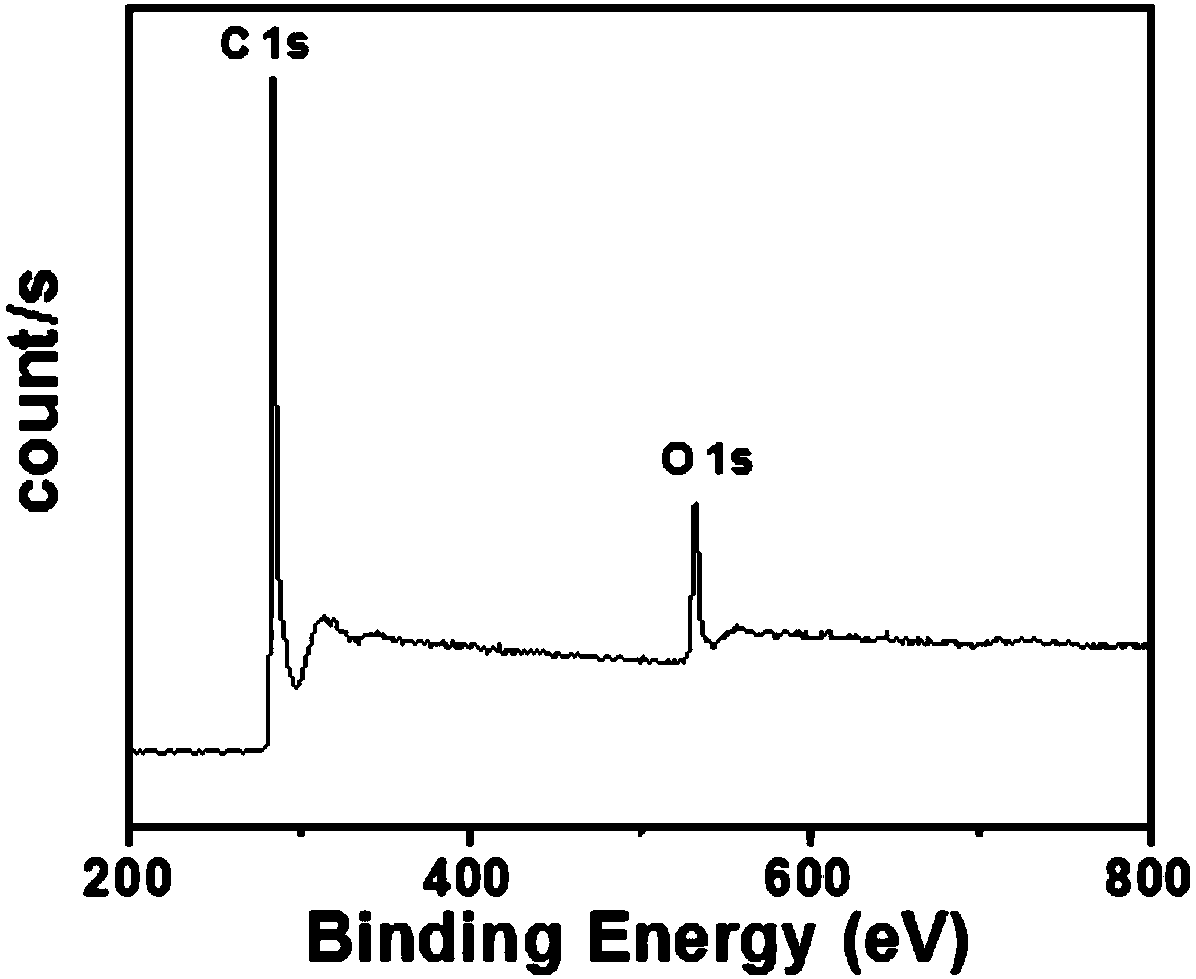

[0026] (2) Set the rotation speed of the ball mill to 500 rpm, and the running time to 36 hours, start the ball mill, and run continuously for 36 hours. Open the air valve, sieve out the sample, and obtain edge carboxylated graphene.

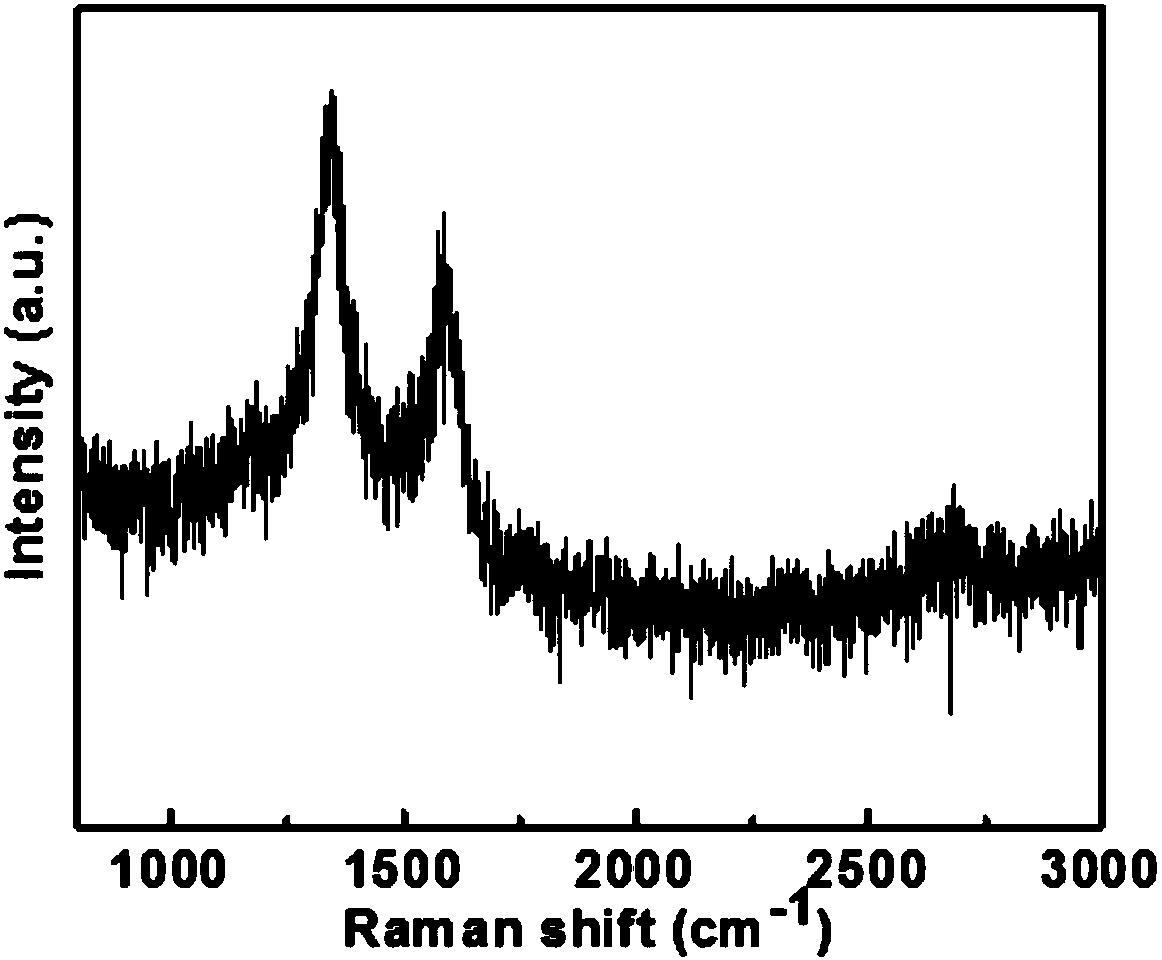

[0027] (3) Put the prepared edge carboxylated graphene in a tube furnace, control the temperature at 1000° C., and reduce it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com