A compound with cyanobenzene as the core and its application in OLED devices

A compound, cyanobenzene technology, applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve efficiency roll-off, low S1 state radiation transition rate, difficult exciton utilization rate and high fluorescence radiation efficiency and other problems, to achieve the effect of strong rigidity, good industrialization prospects, and strong charge transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

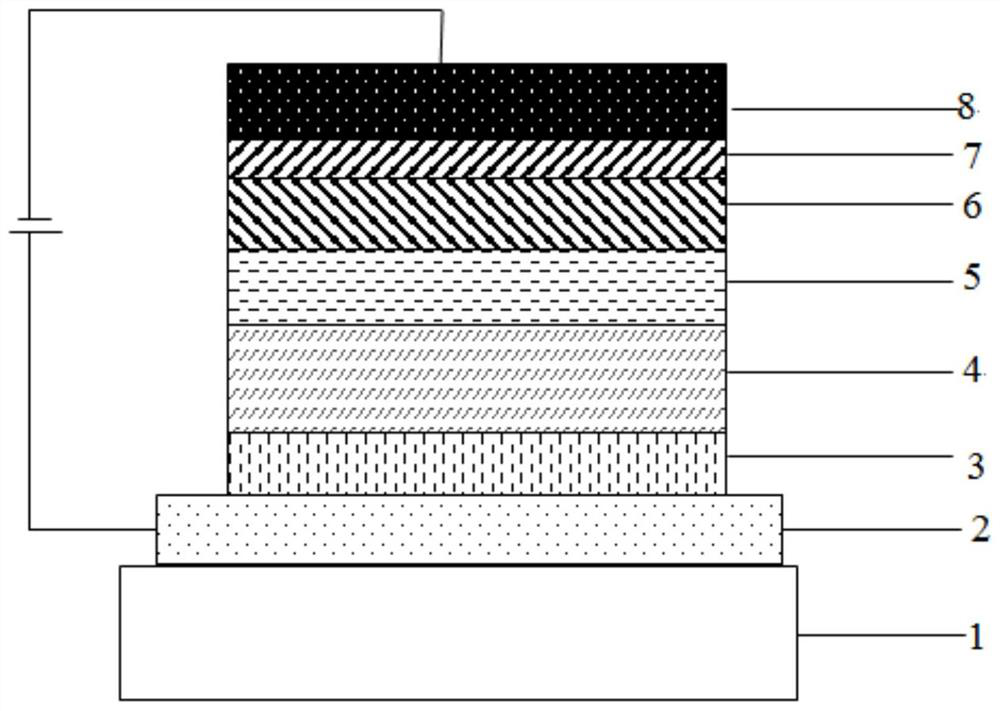

Image

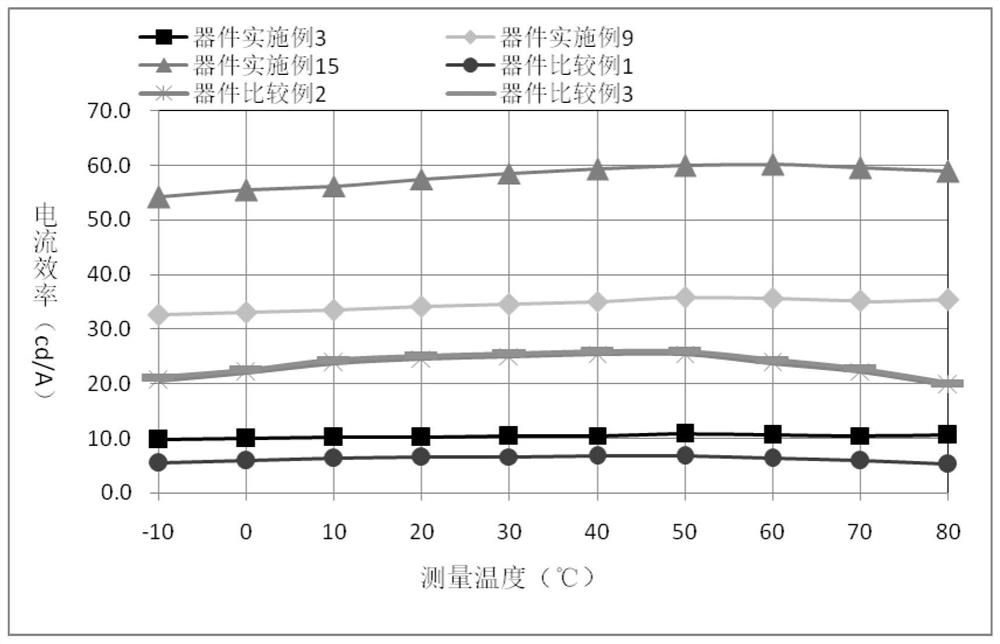

Examples

Embodiment 1

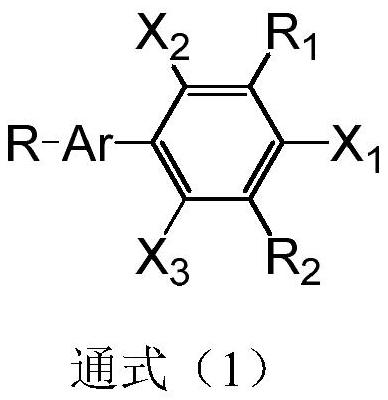

[0045] First provide the intermediate in the general formula (1) The synthetic route of is:

[0046] R 3 Expressed as a hydrogen atom, R 4 When hydrogen atoms are not represented:

[0047]

[0048] Dissolve the bromide raw material I and the amide raw material II in anhydrous toluene, add Pd after deoxygenation 2 (dba) 3 , tri-tert-butylphosphine and sodium tert-butoxide, react at 95-110°C for 10-24 hours under an inert atmosphere, monitor the reaction process with TLC during the reaction process, cool and filter the raw materials after the reaction is complete, and spin the filtrate The solvent is evaporated, and the crude product is passed through a silica gel column to obtain the target compound; the molar ratio of the raw material I to the raw material II is 1:1.0~1.5, Pd 2 (dba) 3 The molar ratio to raw material I is 0.006~0.02:1, the molar ratio of tri-tert-butylphosphine to raw material I is 0.006~0.02:1, and the molar ratio of sodium tert-butoxide to raw mate...

Embodiment 2

[0066] Embodiment 2: the synthesis of compound 3:

[0067]

[0068] Dissolve 0.01mol raw material E1-1 and 0.012mol intermediate M1-1 in 150mL anhydrous toluene, add 0.0005mol Pd after deoxygenation 2 (dba) 3 , 0.015mol tri-tert-butylphosphine and 0.02mol sodium tert-butoxide, and reacted at 110°C for 24 hours under an inert atmosphere. During the reaction, TLC was used to continuously monitor the reaction process. After the raw materials were completely reacted, cooled and filtered, the filtrate was spun Evaporate and remove solvent, thick product crosses silica gel column, obtains intermediate target product; Elemental analysis structure (molecular formula C 43 h 29 N 3 ): theoretical value C, 87.88; H, 4.97; N, 7.15; test value: C, 87.88; H, 4.98; N, 7.14; for 587.25.

Embodiment 3

[0069] Embodiment 3: the synthesis of compound 11:

[0070]

[0071] The preparation method of compound 11 is the same as that of Example 2, except that intermediate M1-2 is used instead of intermediate M1-1. Elemental analysis structure (molecular formula C 55 h 38 N 4 ): theoretical value C, 87.50; H, 5.07; N, 7.42; test value: C, 87.50; H, 5.06; N, 7.43. ESI-MS(m / z)(M + ): The theoretical value is 754.31, and the measured value is 754.66.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com